Welding method of SMD electrolytic capacitor

A technology of electrolytic capacitors and welding methods, which is applied in the direction of assembling printed circuits, electrical components, and printed circuits with electrical components. Effect of Mounting Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The present embodiment provides a welding method for chip electrolytic capacitors, which includes the following steps:

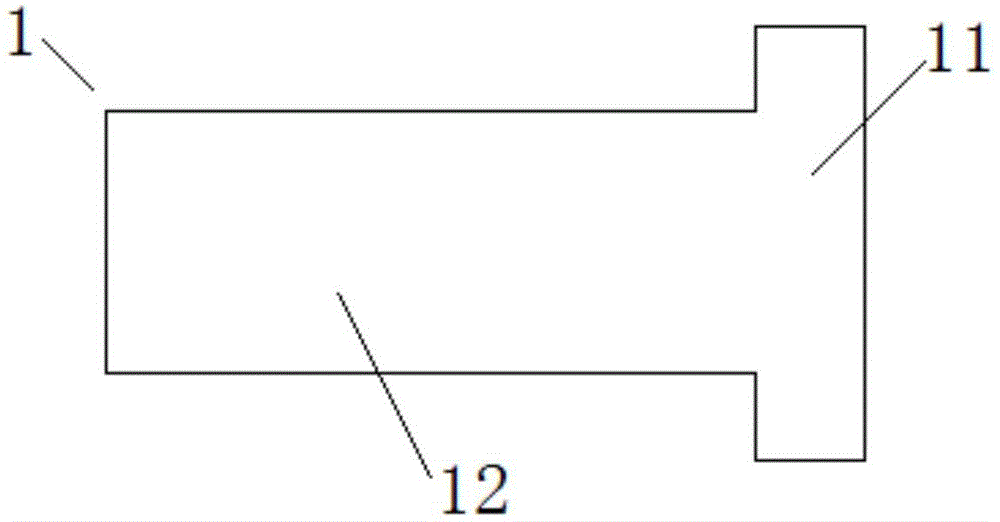

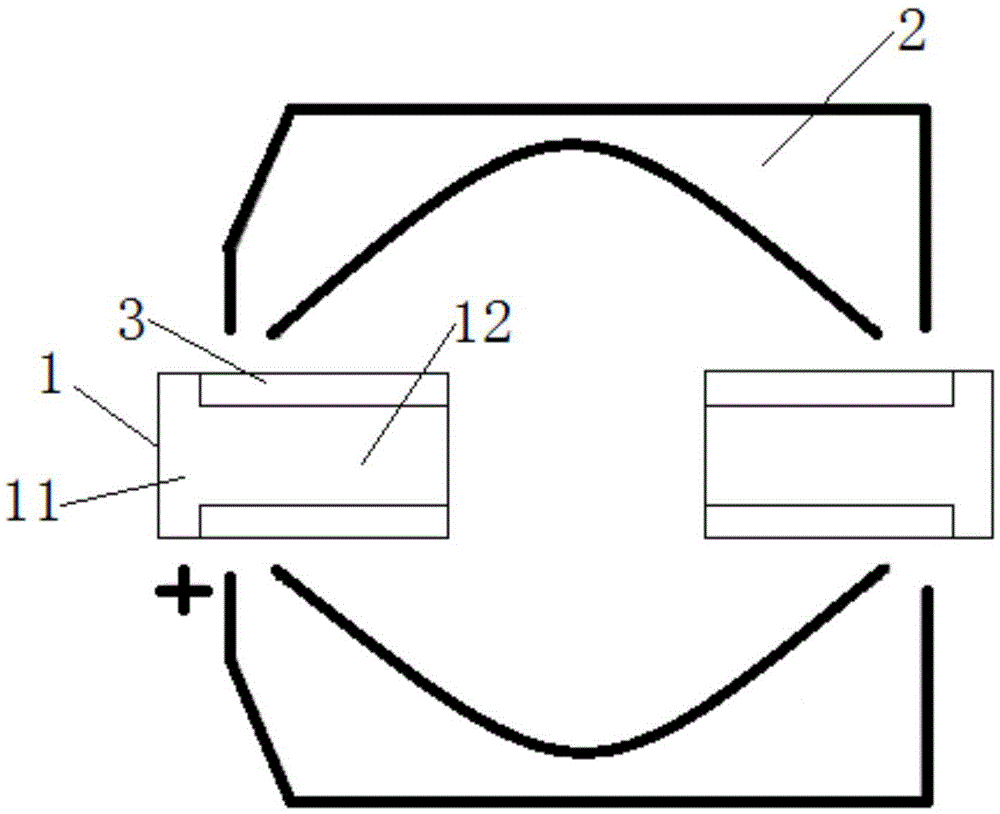

[0030] S1, making a steel mesh, the opening 1 of the welding pad on the steel mesh is T-shaped, and consists of a first rectangular part 11 and a second rectangular part 12 that are vertically connected to each other, such as Figure 1-2 As shown, the length of the first rectangular part 11 of the pad opening 1 is 70-90mil, and the width is 20-30mil; the length of the second rectangular part 12 is 110-130mil, and the width is 40-60mil. In this embodiment , the body diameter of the chip electrolytic capacitor 2 is 8 mm, the length of the first rectangular part 11 of the pad opening 1 is 80 mil, and the width is 20 mil; the length of the second rectangular part 12 is 120 mil, and the width is 48 mil. The short side of the second rectangular part 12 is arranged perpendicular to the long side of the first rectangular part 11, and the short side of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com