Generator for motorcycle

A technology for motorcycles and generators, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/pattern/structure, magnetic circuit stationary parts, etc. Power generation output and power generation efficiency are reduced, and the power loss of the generator is reduced, so as to achieve the effect of increasing power generation output, improving power generation efficiency, and reducing power loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

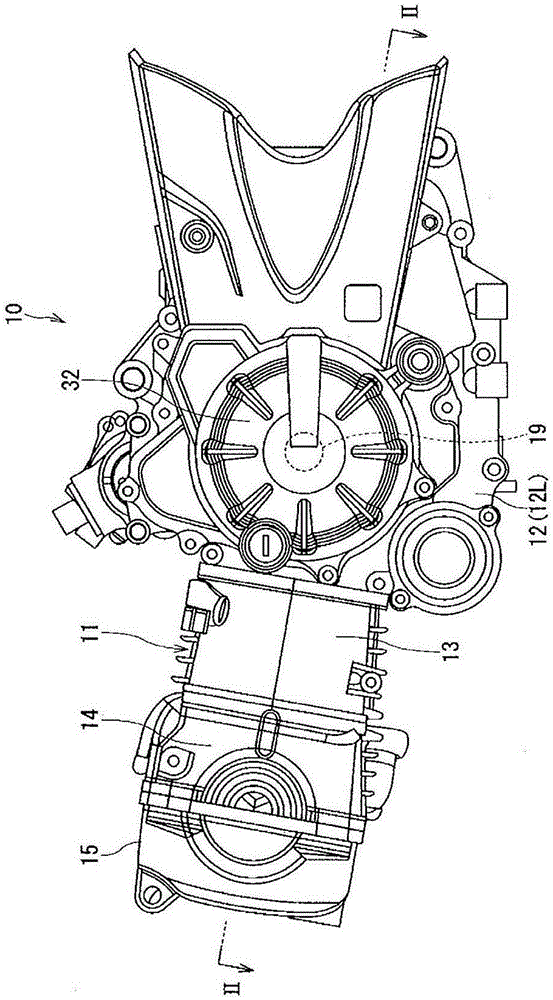

[0064] figure 1 It is a left side view showing the engine unit of the motorcycle to which the first embodiment of the motorcycle generator according to the present invention is applied. figure 1 Among them, the power unit 10 has an air-cooled four-stroke single-cylinder engine 11, and the engine 11 is mainly composed of: a crankcase 12 that rotatably supports and accommodates a crankshaft 19; a cylinder block 13 that is coupled to the end of the crankcase 12; a cylinder head 14 coupled to the cylinder block 13 ; and a head cover 15 coupled to the cylinder head 14 . In addition, the motorcycle generator of the present invention is installed in a power unit of the motorcycle.

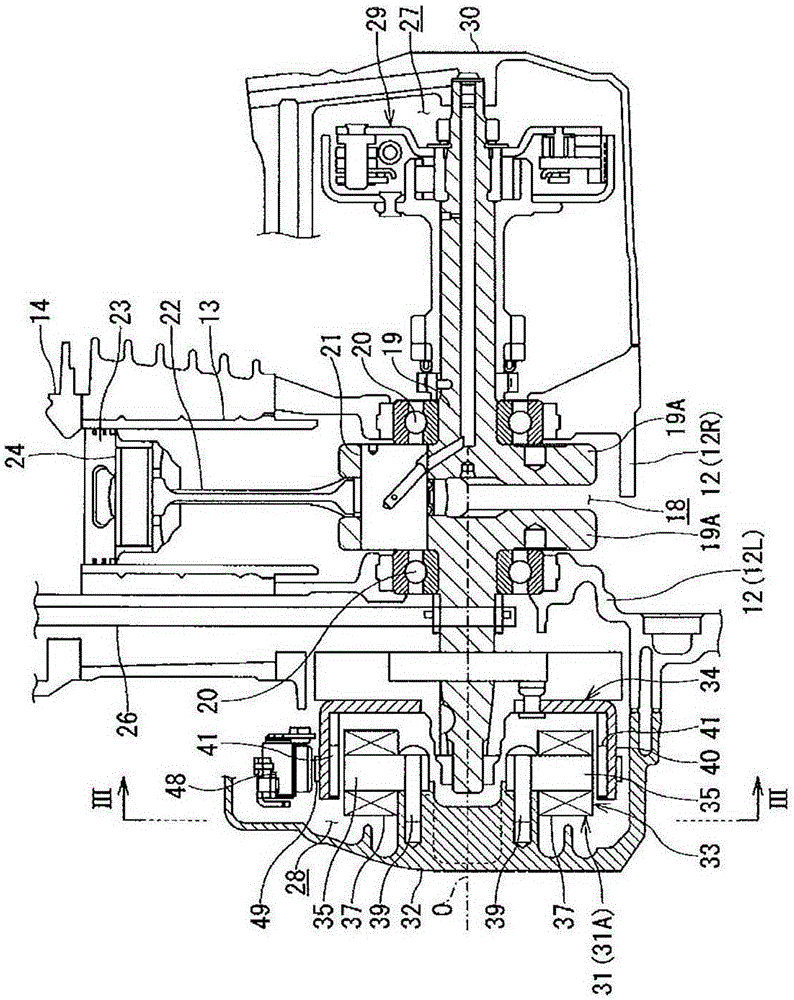

[0065] In this embodiment, the crankcase 12 is divided into two left and right. exist figure 2 In the crankcase 12 , a right crankcase 12R and a left crankcase 12L which are a pair of left and right are mutually coupled to form a crank chamber 18 integrally. In the crank chamber 18 , a crankshaft 1...

no. 2 Embodiment approach

[0088] Next, refer to Figure 12 to Figure 2 0 A second embodiment of the motorcycle generator of the present invention will be described.

[0089] The motorcycle generator according to the second embodiment is installed in the power unit of the motorcycle according to the first embodiment, and it is different from the motorcycle generator shown in the first embodiment. Figure 1 to Figure 3 The structure of the magnetic device 31 is the same, so the same structure is marked with the same symbol to omit or simplify the repeated description.

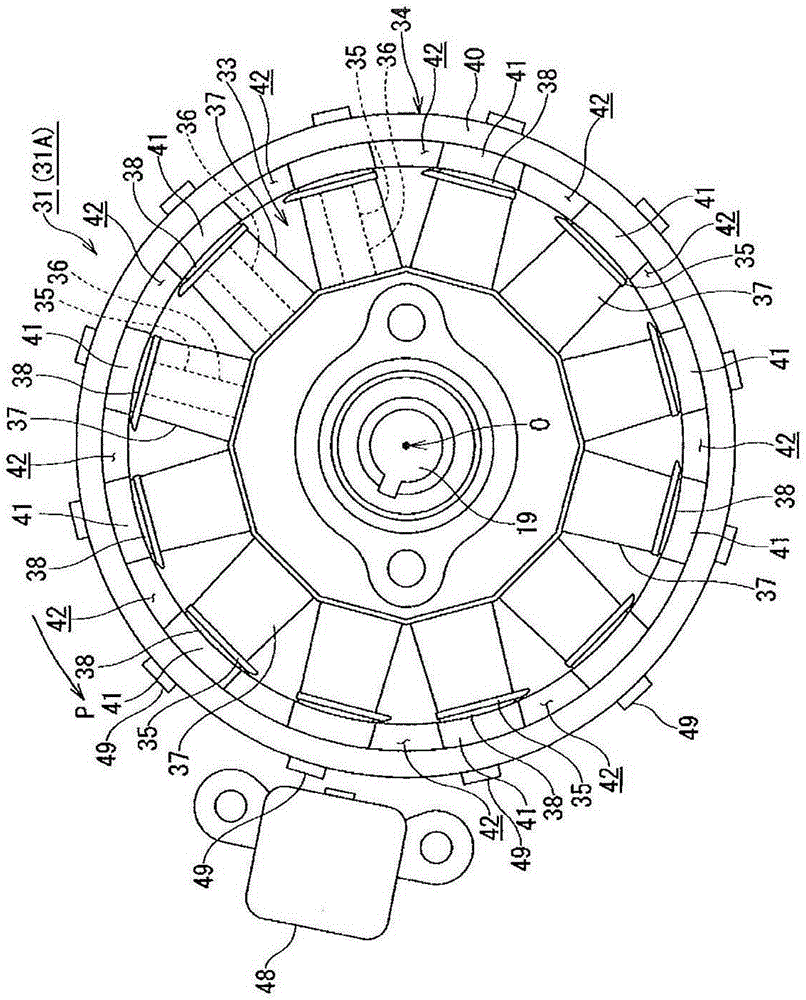

[0090] The motorcycle generator of the second embodiment has a single-phase or three-phase magnetic alternator 31A as a magnetic device. Such as Figure 12 As shown, the magneto generator 31A is configured to include: a stator 33 arranged coaxially with the crankshaft 19 and arranged around the crankshaft 19 ; The rotor 34 is fixed on the left side shaft end of the crankshaft 19, and the rotation direction of the rotor 34 is determined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com