A device and method for rolling silver-magnesium-nickel alloy narrow strip

A silver-magnesium-nickel, narrow-band technology, applied in the field of alloy material processing, can solve the problems of easy generation of burrs, low production efficiency, poor surface quality, etc., to achieve high production efficiency, improve efficiency, and eliminate the effects of spiral ring deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

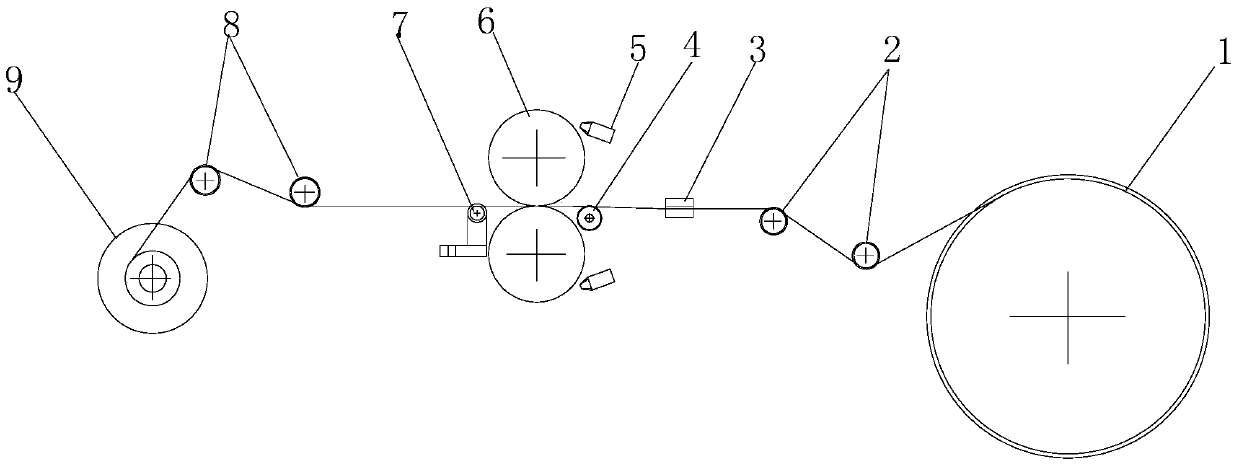

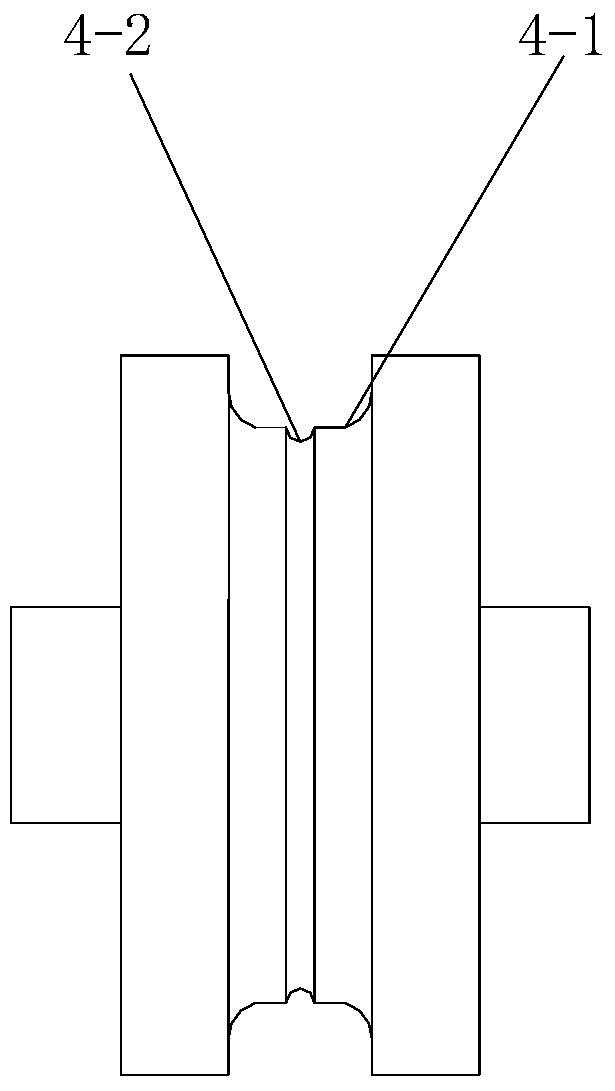

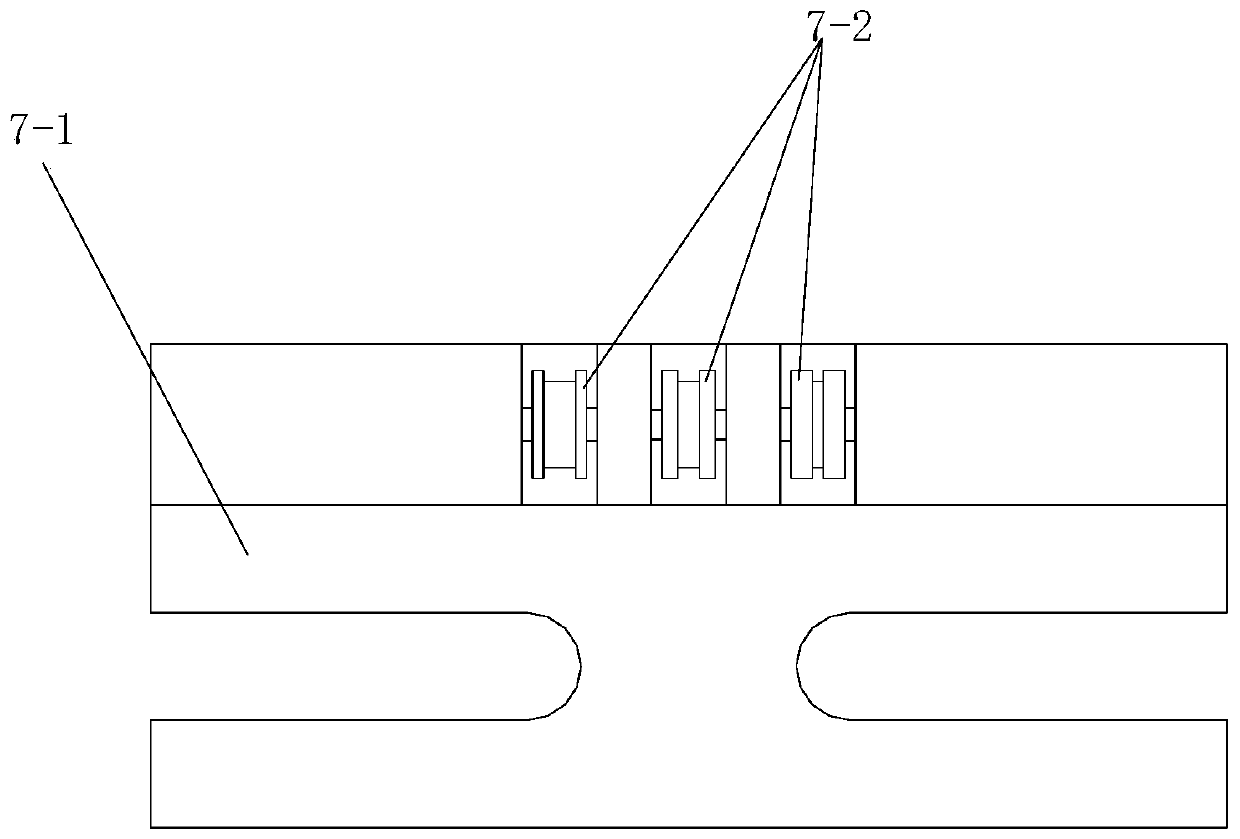

[0038] to combine Figure 1-4 The device for rolling silver-magnesium-nickel alloy narrow strips of the present invention includes a pay-off wheel 1 wound with silver-magnesium-nickel alloy wires, a roller 6 for rolling the silver-magnesium-nickel alloy wires into silver-magnesium-nickel alloy narrow strips And the take-up wheel 9 that is used to wind up the silver-magnesium-nickel alloy narrow strip, the entrance of the roll 6 is provided with a roll guide wheel 4, and the exit of the roll 6 is provided with a straightening mechanism 7, so The entry roller guide wheel 4 is provided with a large guide wheel groove 4-1, and a small guide wheel groove 4-2 is arranged in the described large guide wheel groove 4-1, and the straightening mechanism 7 includes a base 7-1 and a A plurality of guide wheels 7-2 arranged on the base 7-1 are provided with guide wheel grooves on each of the guide wheels 7-2, and the groove widths of the guide wheel grooves on each of the guide wheels 7-2 a...

Embodiment 2

[0046] The specifications of the silver-magnesium-nickel alloy narrow strip to be rolled in this embodiment are: width B=1.5mm, thickness H=0.1mm. to combine Figure 1-4 , the present embodiment utilizes the method for rolling silver-magnesium-nickel alloy narrow strip as described in embodiment 1 and comprises the following steps:

[0047] Step 1. Select the silver-magnesium-nickel alloy wire and determine the rolling pass; according to "the cross-sectional area s of the selected silver-magnesium-nickel alloy wire satisfies: 1.1S≤s≤1.25S, wherein S is the silver to be rolled The cross-sectional area of the magnesium-nickel alloy narrow strip, the units of S and s are mm 2 "Principle, the wire diameter of the silver-magnesium-nickel alloy wire material that the present embodiment selects is 0.48mm, and the determined rolling pass is two passes;

[0048] Step 2, use the roll 6 to carry out the first rolling of the silver-magnesium-nickel alloy wire, and use the compressed a...

Embodiment 3

[0052] The specifications of the silver-magnesium-nickel alloy narrow strip to be rolled in this embodiment are: width B=2.0mm, thickness H=0.15mm. to combine Figure 1-4 , the present embodiment utilizes the method for rolling silver-magnesium-nickel alloy narrow strip as described in embodiment 1 and comprises the following steps:

[0053] Step 1. Select the silver-magnesium-nickel alloy wire and determine the rolling pass; according to "the cross-sectional area s of the selected silver-magnesium-nickel alloy wire satisfies: 1.1S≤s≤1.25S, wherein S is the silver to be rolled The cross-sectional area of the magnesium-nickel alloy narrow strip, the units of S and s are mm 2 "Principle, the wire diameter of the silver-magnesium-nickel alloy wire material selected in the present embodiment is 0.65mm, and the determined rolling passes are two passes;

[0054] Step 2, use the roll 6 to carry out the first rolling of the silver-magnesium-nickel alloy wire, and use the compresse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com