Polyurethane track made of polyurethane fiber waste and preparation method thereof

A technology of spandex waste silk and polyurethane, which is applied in the field of polyurethane application, can solve the problem of high cost of runways, and achieve the effects of reducing sports injuries, high safety, and preventing sports injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

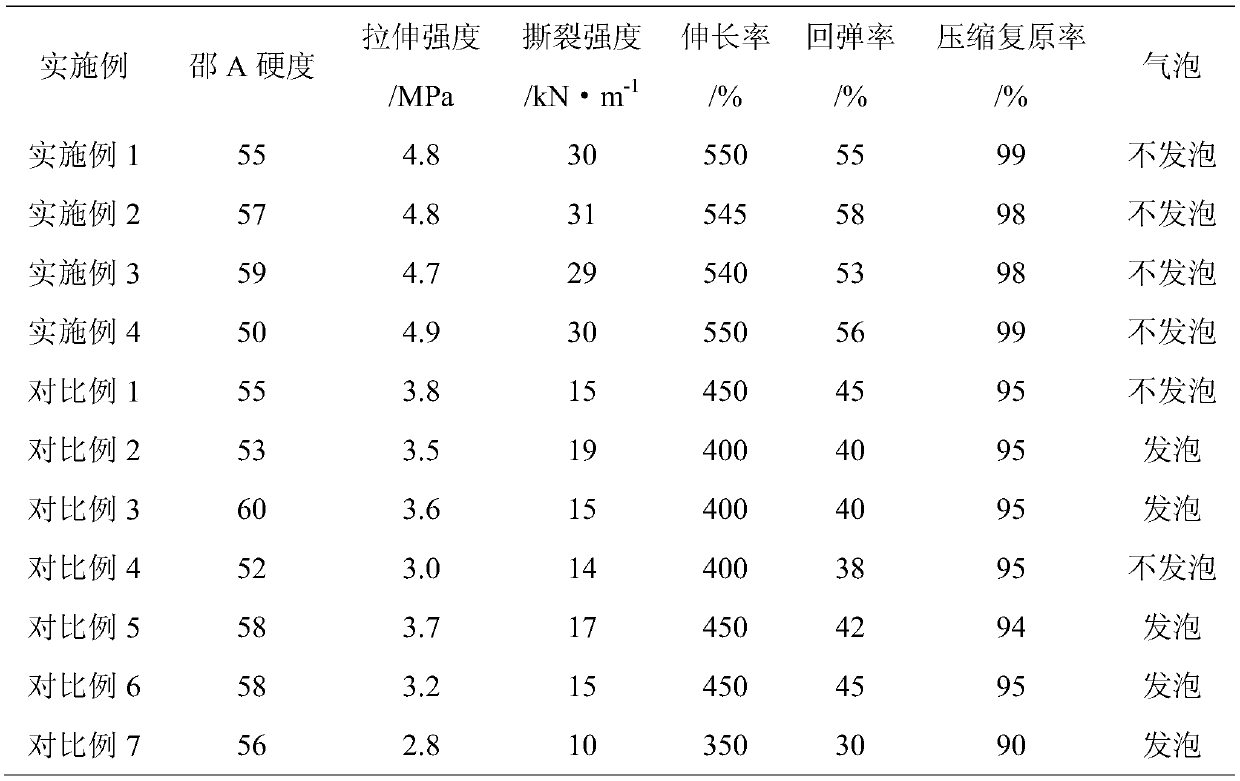

Examples

Embodiment 1

[0019] A. Prepolymer components: 25 parts of MDI, 45 parts of polyether polyol (N-2020(Mn=2000));

[0020] B. Curing agent components: 15 parts of polyether glycol (polyether glycol DL-2000 (Mn=2000)), 10 parts of polyether triol (MN3050 (Mn=3000)), chain extender MOCA5 Parts, plasticizer 5230 parts of chlorinated paraffin, 30 parts of filler kaolin, 5 parts of pigments, catalyst (mixture of lead isooctanoate and zinc isooctanoate at a mass ratio of 1:2) 0.5 parts, thixotropic agent (gas-phase white carbon black) 1 part, antioxidant (antioxidant 1010) 0.15 part, ultraviolet absorber (UV-9) 0.1 part, spandex waste silk (diameter 25μm, length 5mm) 60 parts. The waste spandex yarn is the waste spandex yarn after degreasing and finishing with softener (polyether modified silicone oil H-193 (Jiangxi Haiduo Chemical Co., Ltd.)).

[0021] The preparation method of the above-mentioned polyurethane high elasticity track includes the following steps: (1) The polyether polyol in component A ...

Embodiment 2

[0025] A. Prepolymer components: 30 parts of MDI, 45 parts of polyether polyol (N-2020(Mn=2000));

[0026] B. Curing agent components: 10 parts of polyether diol (polyether diol DL-2000 (Mn=2000)), 20 parts of polyether triol (MN3050 (Mn=3000)), chain extender MOCA10 Parts, plasticizer chlorinated paraffin 5220 parts, filler kaolin 25 parts, pigment 8 parts, catalyst (a mixture of lead isooctanoate and zinc isooctanoate at a mass ratio of 1:2) 1 part, thixotropic agent (gas phase white carbon black) 3 parts, 0.1 part of antioxidant (antioxidant 1010), 0.15 part of ultraviolet absorber (UV-9), 55 parts of waste spandex (diameter 35μm, length 3mm). The waste spandex yarn is the waste spandex yarn that has been degreasing and treated with a softener (polyether modified silicone oil ZBH-2070 (Qingdao Zhongbao Chemical Co., Ltd.)).

[0027] The preparation method of the above-mentioned polyurethane highly elastic racetrack includes the following steps: (1) The polyether polyol in compo...

Embodiment 3

[0031] A. Prepolymer components: 40 parts of MDI, 45 parts of polyether polyol (N-2020(Mn=2000));

[0032] B. Curing agent components: 15 parts of polyether glycol (polyether glycol DL-2000 (Mn=2000)), 15 parts of polyether triol (MN3050 (Mn=3000)), chain extender MOCA8 Parts, plasticizer 5230 parts of chlorinated paraffin, 30 parts of filler kaolin, 10 parts of pigments, 2 parts of catalyst (mixture of lead isooctanoate and zinc isooctanoate at a mass ratio of 1:2), thixotropic agent (gas phase white carbon black) 5 parts, 0.1 part of antioxidant (antioxidant 1010), 0.1 part of ultraviolet absorber (UV-9), 50 parts of spandex waste silk (50μm in diameter and 5mm in length). The waste spandex yarn is the waste spandex yarn after degreasing and finishing with a softener (polyether modified silicone oil SM-601 (Laiyang Shunming Chemical Co., Ltd.)).

[0033] The preparation method of the above-mentioned polyurethane high elasticity track includes the following steps: (1) The polyeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com