A kind of alloy ingot containing magnesium and cadmium and preparation method thereof

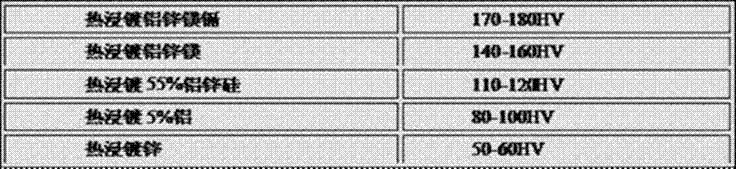

A technology of alloy ingots and alloy elements, which is applied in the field of alloy ingots containing magnesium and cadmium and its preparation, can solve problems such as defects in machining, achieve superior scratch resistance, save zinc resources, and reduce resource consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

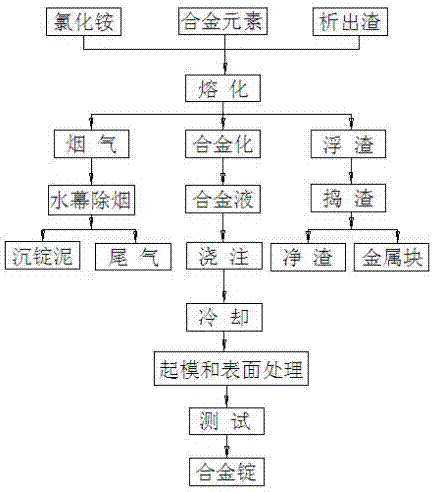

[0027] A method for preparing an alloy ingot containing magnesium and cadmium, which is characterized in that it comprises the following steps:

[0028] (1) Ingredients:

[0029] The alloying elements are proportioned according to the mass percentage: aluminum 50% to 58%, silicon 1.2% to 1.8%, magnesium 1% to 3%, cadmium 0.5% to 2%, and the balance is zinc;

[0030] (2) Smelting:

[0031] Put the well proportioned metal into the smelting furnace, raise the temperature to 650°C, stir to make the components uniformly alloyed to avoid aluminum segregation, and then sample from the furnace mouth to check whether the composition is uniform;

[0032] (3) Pouring:

[0033] Use movable movable zinc chute for pouring;

[0034] (4) Cooling:

[0035] When the center temperature of the alloy liquid drops to about 469℃, observe that the diameter of the non-condensed area on the upper surface is within 200mm and slowly sprinkle water, and gradually increase the amount of watering;

[0036] (5) Mold drawi...

Embodiment

[0046] Take the percentage by weight: aluminum 56%, silicon 1.5%, magnesium 2%, cadmium 1.5%, and the balance is zinc. Heat the metal in an intermediate frequency induction electric furnace with a good ratio to 650°C and stir to make the ingredients uniform Alloying to avoid aluminum segregation, and then sampling at the furnace mouth, laboratory testing whether the composition is uniform, the furnace is cooled to 630 ℃ for refining and scum, and then cooled to 550 ℃ for slagging and pouring, and the time is not suitable Too fast, otherwise it is easy to produce bubbles, slag inclusions, and crack defects. The ingot is poured for about 3 minutes each time, and the skin is quickly rubbed after the casting is completed. When the center temperature of the alloy liquid drops to about 469°C, observe the diameter of the uncondensed area on the upper surface Slowly sprinkle water within 200mm and gradually increase the amount of water. In the process of drawing out, check whether the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com