Aluminum-strengthened maraging steel and preparing method thereof

A maraging steel, martensitic steel technology, applied in the field of new aluminum reinforced martensitic steel, can solve the problems of general fatigue performance, insufficient steel stiffness, increased cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

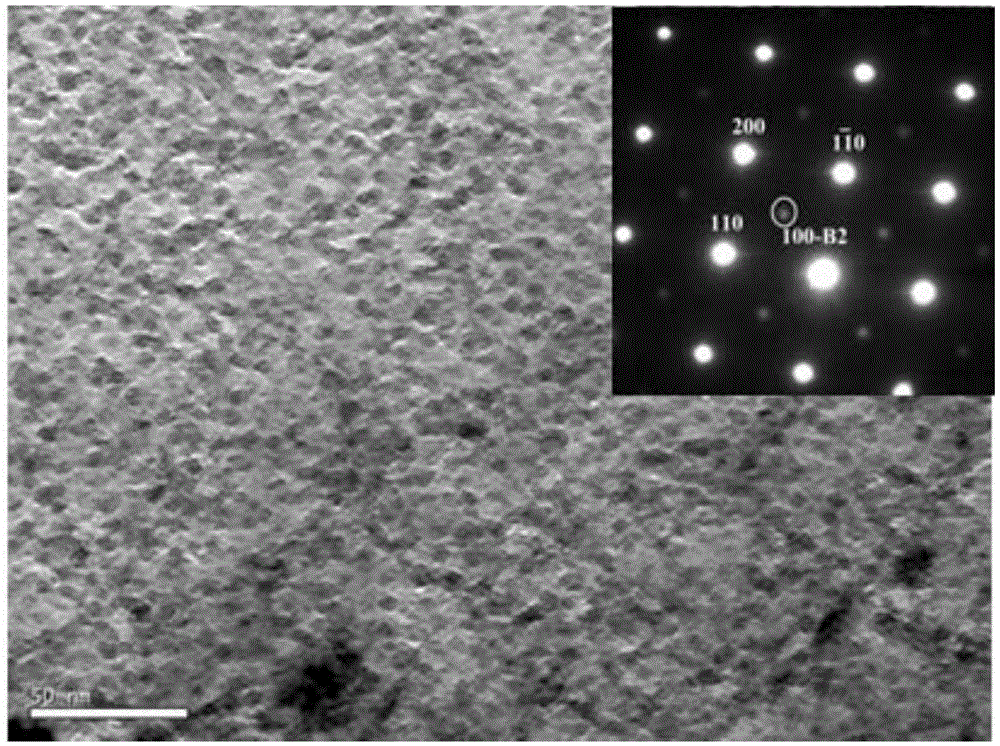

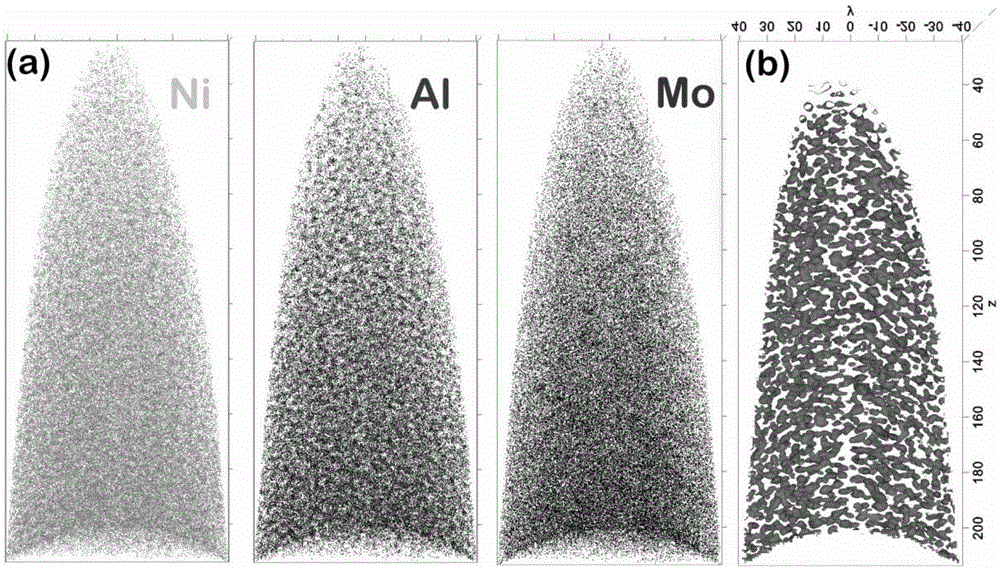

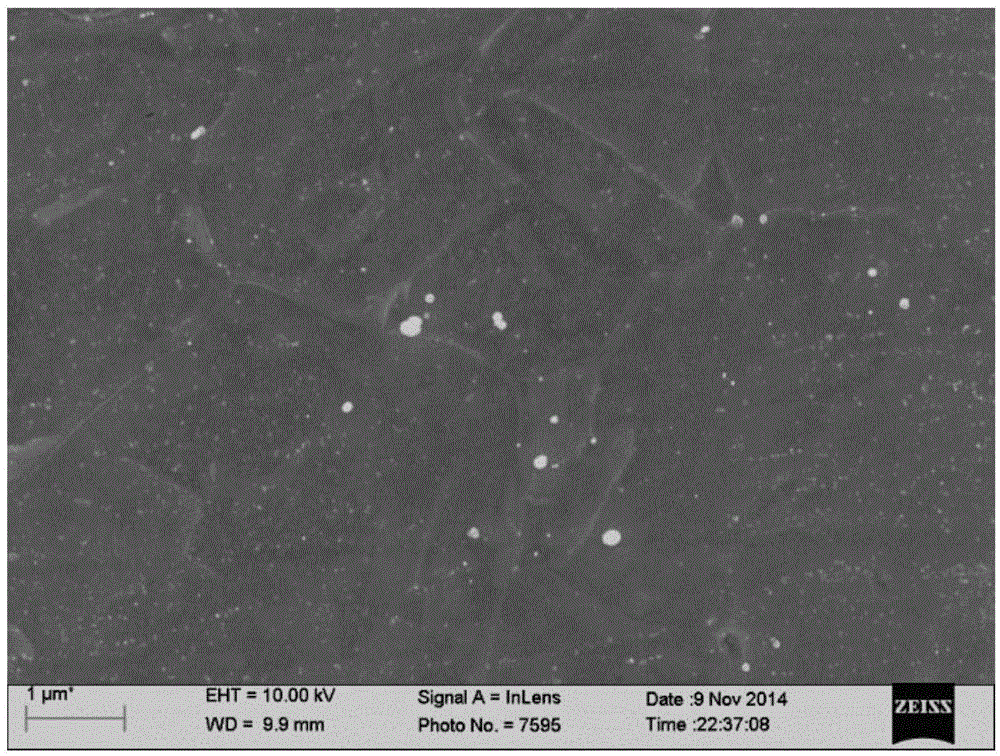

[0051] According to the composition range of the new aluminum-reinforced maraging steel of the present invention, the inventive steel AFM1-10 and two comparison steels CS1 and CS2 were smelted. According to the ingredient scheme in Table 1, the ingredients were mixed, and the smelting and casting were carried out in a high-vacuum argon atmosphere arc melting furnace. The obtained ingot was solution treated at 1200° C. for 24 hours and then air-cooled to room temperature. Afterwards, 70% of the plate is cold-rolled to an appropriate thickness, and the recovery treatment is carried out at 950 ° C for 15 minutes, and the water is quenched to room temperature. Then aging treatment was carried out at different temperatures and times, and cooled to room temperature in air. Thus, test steels AFM1-10 and comparative steels CS1 and CS2 were produced.

[0052] Table 1. Alloy compositions (wt%) of the inventive steel AFM1-8 and the comparative steels CS1 and CS2

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com