Ramie degumming method

A degumming method and ramie technology, applied in the field of hemp textiles, can solve the problems of complex degradation mechanism, complex ramie gum components, and difficulty in achieving the desired effect by biological enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 biological enzyme

[0035] Use the bacteria strain DickeyadadantiiCGMCC5522 to inoculate the improved broth culture solution for 5h activation to make the dormant bacteria become active bacteria suspension, take 1.0ml bacteria suspension and dilute 10 5 After doubling, spread evenly on the selected culture plate and cultivate for 22 hours to obtain typical colonies. Take 1 typical colony and place it in a test tube with improved broth culture solution for dispersion, then pour it into a conical flask filled with 300ml of improved broth culture solution. medium, 35°C, 160rpm, cultured for 6h; transferred to the fermentation medium, 34-36°C, 200r / min, micro-aeration (0.4MPa compressed air flow rate 0.3m 3 / m 3 h) Culture for 6 h.

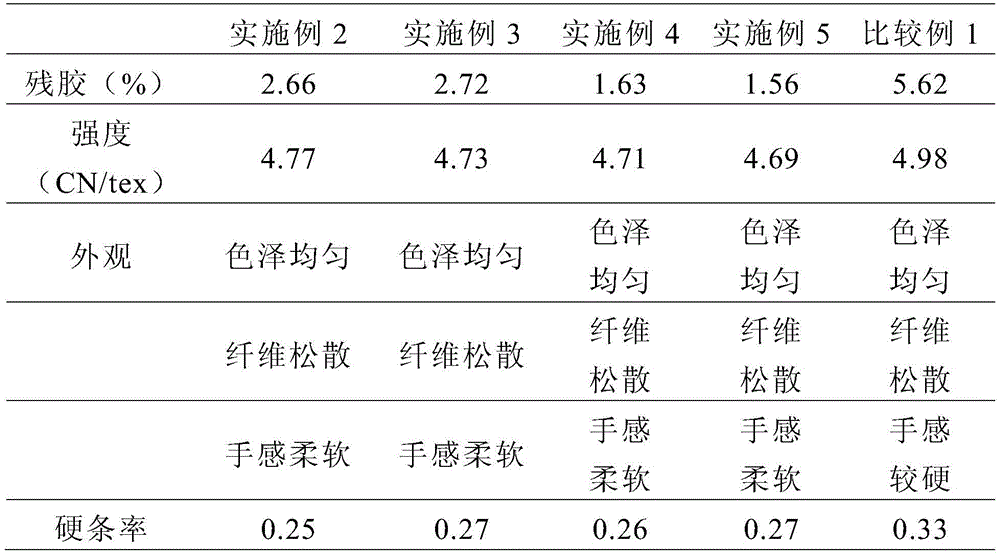

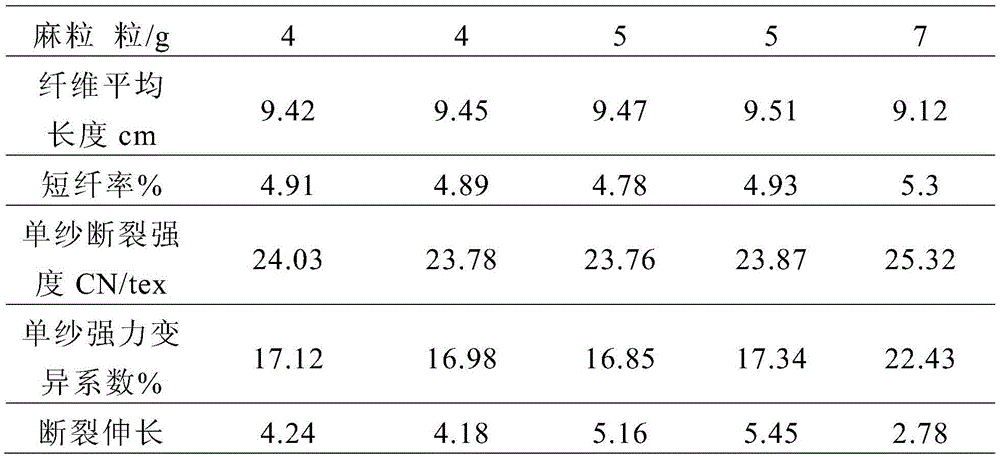

Embodiment 2

[0037]Composite biological enzyme fermentation broth, the total enzyme activity of the fermentation broth is 20000U / ml, wherein 87% is the biological enzyme prepared in Example 1, 5% is commercially available polygalacturonase, and 5% is xylanase , 1% cellulase, 2% glucosidase;

[0038] Raw hemp is made of ramie produced in Yuanjiang, Hunan, microwave dried to a water content of about 5%, rubbed and pressed, and tied into hemp handles of 600-700 g / handle;

[0039] For the first degumming, put the crushed ramie in a cage and soak in enzyme, control the weight ratio of degumming enzyme solution to hemp handle to 5:1, soak for 20 minutes, dilute, control the bath ratio to 10:1, keep warm at 40°C for degumming, and repeat The dosage of the enzyme is 1000U / g, the degumming time is 2 hours, ventilate, or swing the handle;

[0040] For the second degumming, add 500U / g compound enzyme, the liquor ratio is 12:1, the degumming temperature is 40°C, and continue degumming for 2 hours;

...

Embodiment 3

[0043] Compound biological enzyme fermentation broth, the total enzyme activity of the fermentation broth is 20000U / ml, wherein 87.5% is the biological enzyme prepared in Example 1, 4.5% is commercially available polygalacturonase, and 4.5% is xylanase , 1% cellulase, 2.5% glucosidase;

[0044] Raw hemp is made of ramie produced in Yuanjiang, Hunan Province, microwave-dried to a water content of about 4%, rubbed and pressed, and tied into hemp handles of 600-700 g / handle;

[0045] For the first degumming, put the crushed ramie in a cage and soak the enzyme, control the weight ratio of the degumming enzyme solution to the hemp handle to 6:1, soak for 25 minutes, dilute and control the bath ratio to 10:1, keep warm at 40°C for degumming, and repeat The dosage of the enzyme is 900U / g, the degumming time is 2 hours, ventilate, and swing the handle;

[0046] For the second degumming, add 500U / g compound enzyme, the liquor ratio is 12:1, the degumming temperature is 40°C, and conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com