Finned heat exchange pipe formed through die pressing and vacuum brazing

A heat exchange tube and fin technology, applied in the field of refrigeration and air-conditioning equipment, can solve the problems of unstable molding quality, high production cost, poor pressure resistance, etc., and achieves enhanced mold versatility, high one-time yield, and freedom high-combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

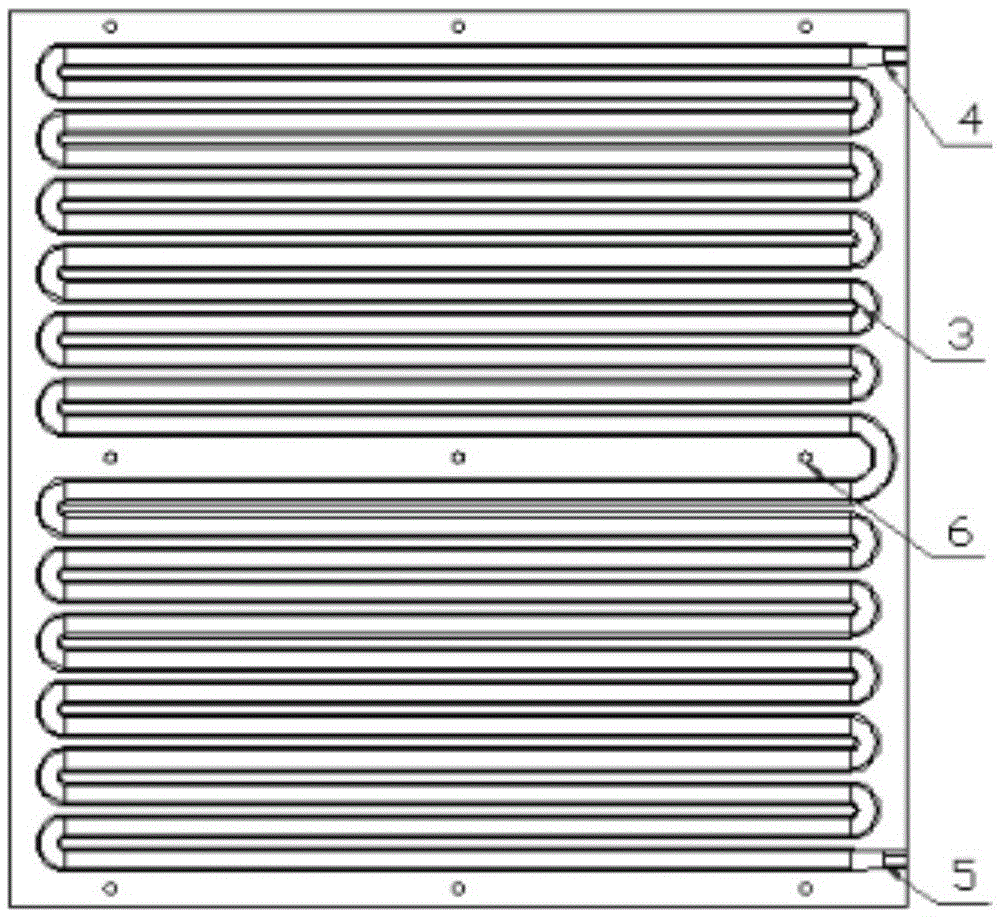

[0026] The present invention is described in detail below in conjunction with accompanying drawing: Figures 3 to 7 As shown, the finned heat exchange tube of the present invention is composed of A base tube fin 1, B base tube fin 2, heat exchange tube flow channel 3, inlet connection port 4, outlet connection port 5, and reinforcement hole 6, The A base tube fins 1 and B base tube fins 2 are base tube fins with the same shape, which constitute a half-width structure of an integral finned heat exchange tube; the A base tube fins 1, B The base tube fins 2 are respectively designed with S-shaped continuous smooth semi-structured heat exchange tube flow channels 3, and the area outside the heat exchange tube flow channel 3 is designed as fins 10 on the extended surface of the heat exchange tube flow channel 3; The fins 1 of the base tube of A and the fins 2 of the base tube of B are symmetrically distributed, and are molded and vacuum brazed to form an integral finned heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com