Brushless double-fed motor direct torque control method capable of reducing torque pulsation

A direct torque control, doubly-fed motor technology, applied in the field of control, can solve the problems of increasing torque ripple amplitude, unable to realize complete compensation of torque and flux linkage errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

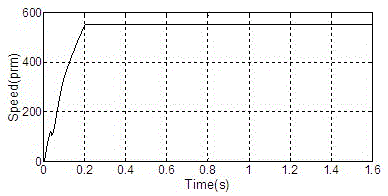

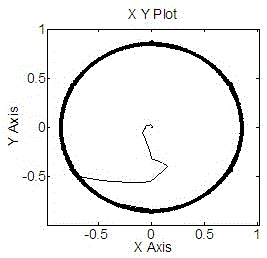

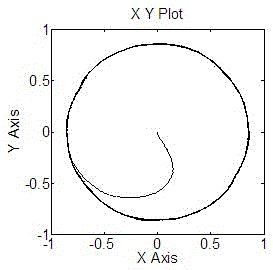

[0031] see figure 1 , the brushless doubly-fed motor controller used in the present invention mainly includes a speed PI regulator, a torque observer, a flux observer, a torque PI controller, a flux PI controller, a 3 / 2 coordinate transformer, an MT / αβ coordinate converter, space voltage vector PWM generator, incremental encoder and voltage and current sensor, the power grid is directly connected to the power winding of the brushless doubly-fed motor, and in turn through the rectifier, DC bus capacitor, inverter and control The windings are connected; the signal of the voltage and current sensor is connected to the flux observer and the torque observer respectively after coordinate transformation by the 3 / 2 converter; the flux deviation signal is connected to the input end of the flux linkage PI controller; the torque deviation signal is connected to the rotation The input terminal of the torque PI controller is connected; the output of the flux linkage PI controller, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com