Manufacturing method of grain oriented electrical steel sheet

A technology of electromagnetic steel sheet and manufacturing method, applied in manufacturing tools, inorganic material magnetism, furnace and other directions, can solve the problems of poor magnetic properties, insufficient control of solid solution elements, insufficient fine precipitation of inhibitors, etc. cost-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

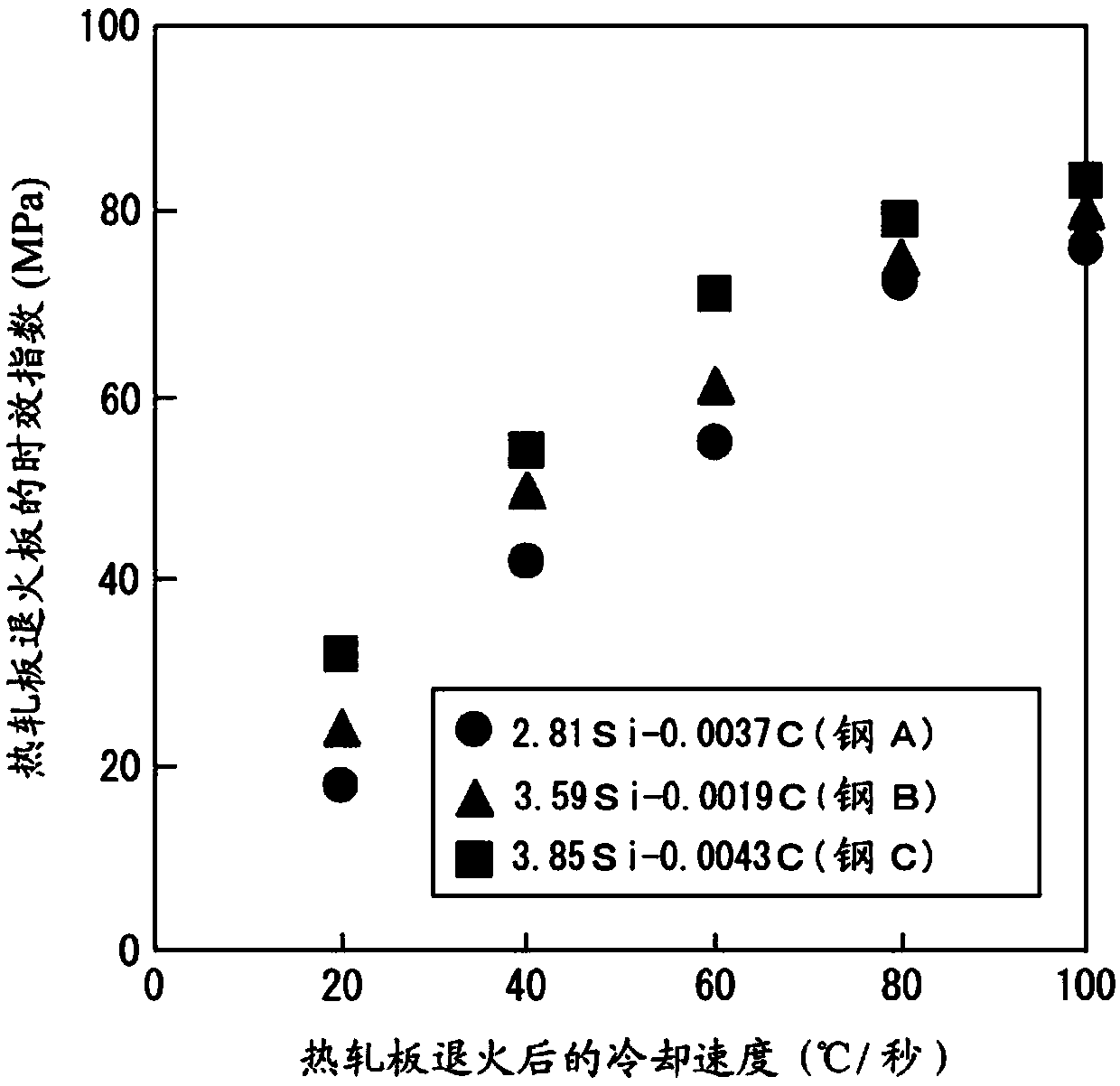

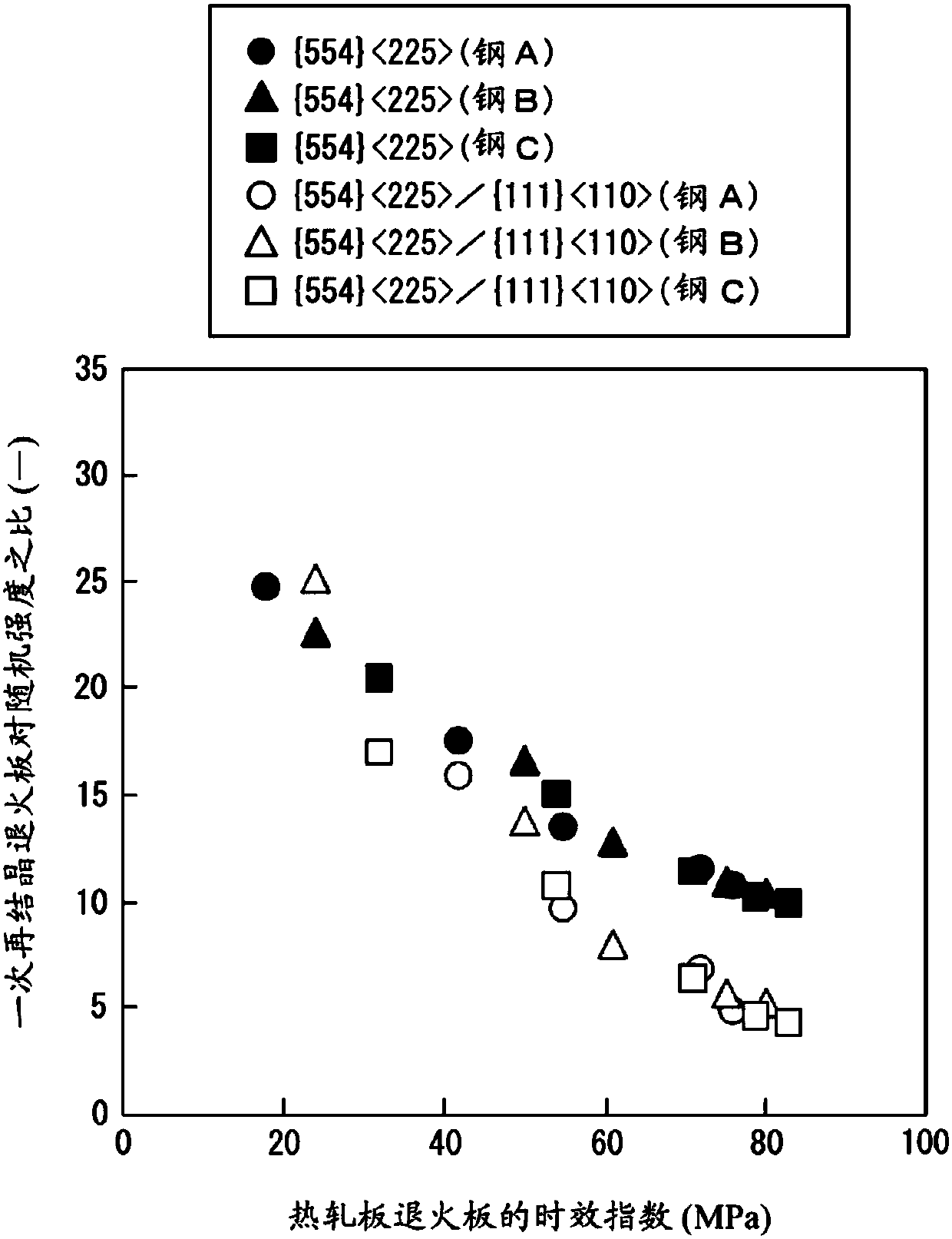

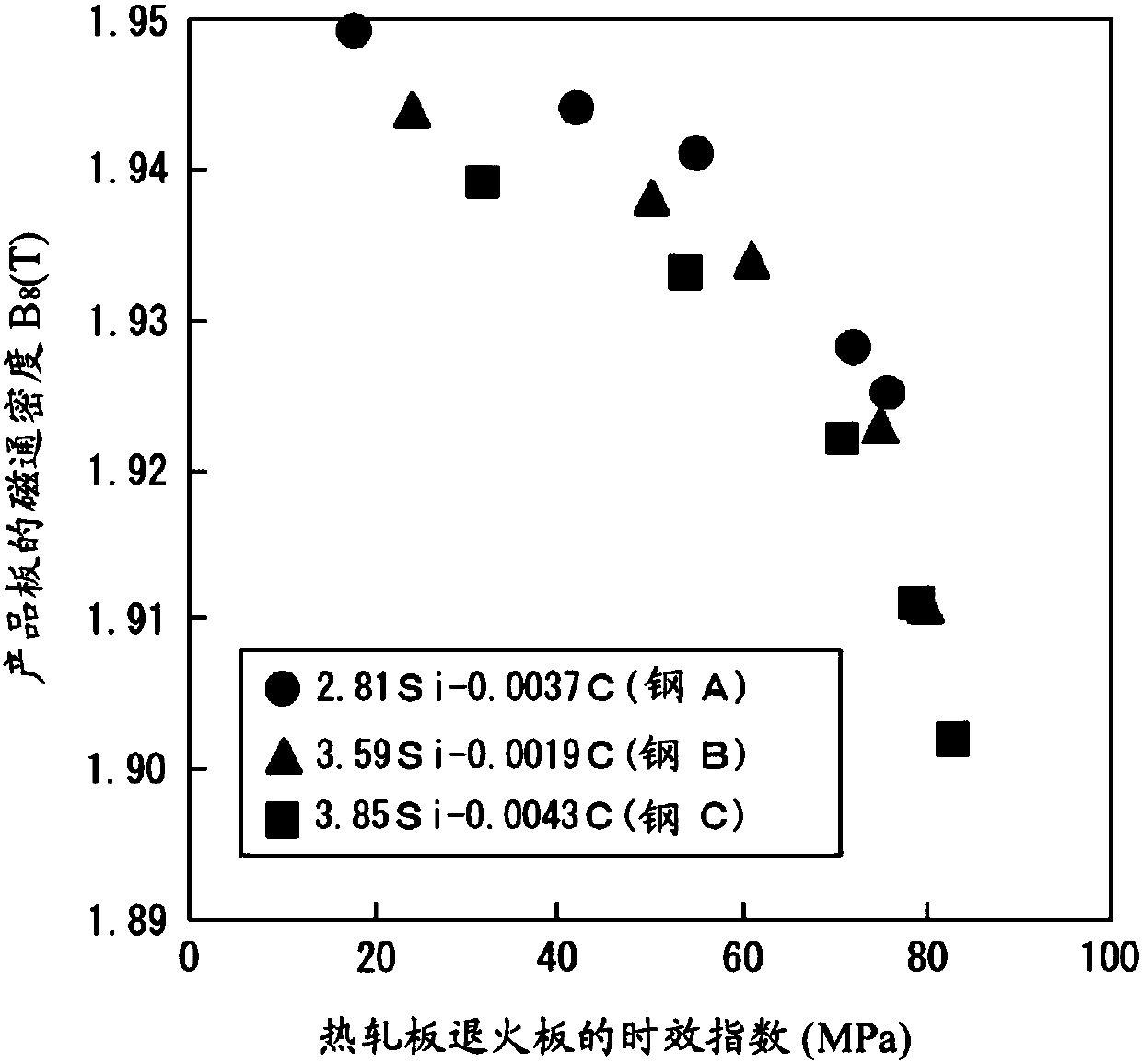

[0131] A steel slab having the composition shown in Table 1 was heated to 1180° C., and then hot rolled to a thickness of 2.3 mm. Next, after annealing the hot-rolled sheet at 1020°C for 60 seconds, cooling at an average cooling rate of 40°C / s between 800°C and 200°C, and then cold rolling to a thickness of 0.23mm, and then in a wet hydrogen-nitrogen mixed gas Primary recrystallization annealing was performed at 820° C. for 120 seconds in the atmosphere. The rate of temperature increase between 500°C and 700°C during the primary recrystallization annealing was 20°C / sec.

[0132] Next, an annealing separator mainly composed of MgO is coated on the surface of the steel sheet, and then secondary recrystallization annealing is performed at 1180°C for 50 hours as a cleaning annealing, and then a phosphate-based insulating tension coating is applied and Baking and flattening annealing for the purpose of flattening the steel strip were performed to produce products.

[0133] The magn...

Embodiment 2

[0137] Billets No. 3 and No. 4 in Table 1 were heated to 1220 °C and then hot rolled to various thicknesses shown in Table 2. Next, after annealing the hot-rolled sheet at 1050°C for 30 seconds, cooling at an average cooling rate of 20°C / s between 800°C and 200°C, and then cold-rolling to a thickness of 0.20mm, and then cooling in a wet hydrogen-nitrogen mixed gas Primary recrystallization annealing was performed at 820° C. for 120 seconds in the atmosphere. The rate of temperature increase between 500°C and 700°C during the primary recrystallization annealing was 30°C / sec.

[0138] Next, an annealing separator is coated on the surface of the steel sheet, and MgO and 10 parts by mass of MgSO are added to 100 parts by mass of MgO in the annealing separator. 4 , and then perform secondary recrystallization annealing that doubles as cleaning annealing at 1180°C for 50 hours, and then apply a phosphate-based insulating tension coating and bake it, and flattening annealing for the...

Embodiment 3

[0143] Steel slabs containing various compositions shown in Table 3 were heated to 1220° C., and then hot rolled to a thickness of 2.7 mm. Next, it is rolled to an intermediate thickness of 2.2mm by the first cold rolling, and then intermediate annealing is performed at 950°C for 60 seconds, and then cooled at an average cooling rate of 40°C / sec between 800°C and 200°C, and then passed through the second pass. After cold rolling twice to a final thickness of 0.23 mm, primary recrystallization annealing was performed at 840° C. for 10 seconds. The rate of temperature increase between 500°C and 700°C during the primary recrystallization annealing was 40°C / sec.

[0144] Then, nitriding treatment was performed at 600° C. for 3 minutes in a cyanate bath. Next, an annealing separator mainly composed of MgO is coated on the surface of the steel sheet, and secondary recrystallization annealing is performed at 1200°C for 50 hours, which is also used as a cleaning annealing, and then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com