A precise laser polishing device and method thereof

A laser polishing and precision technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that it is difficult to achieve micro-nano scale laser polishing effect, and achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

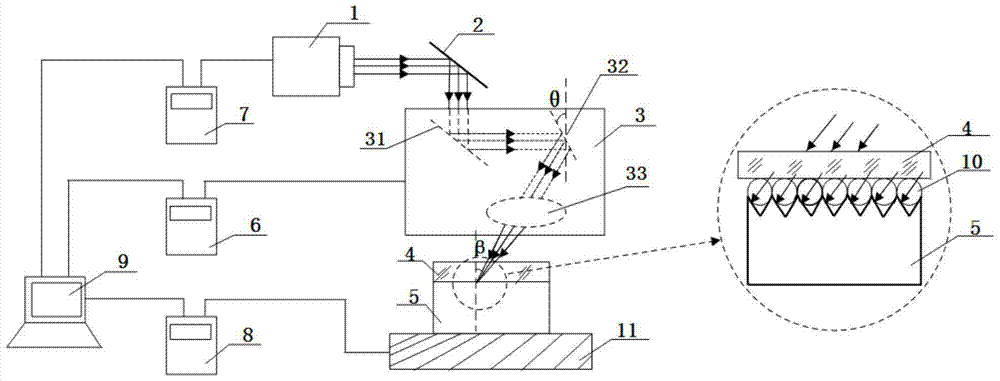

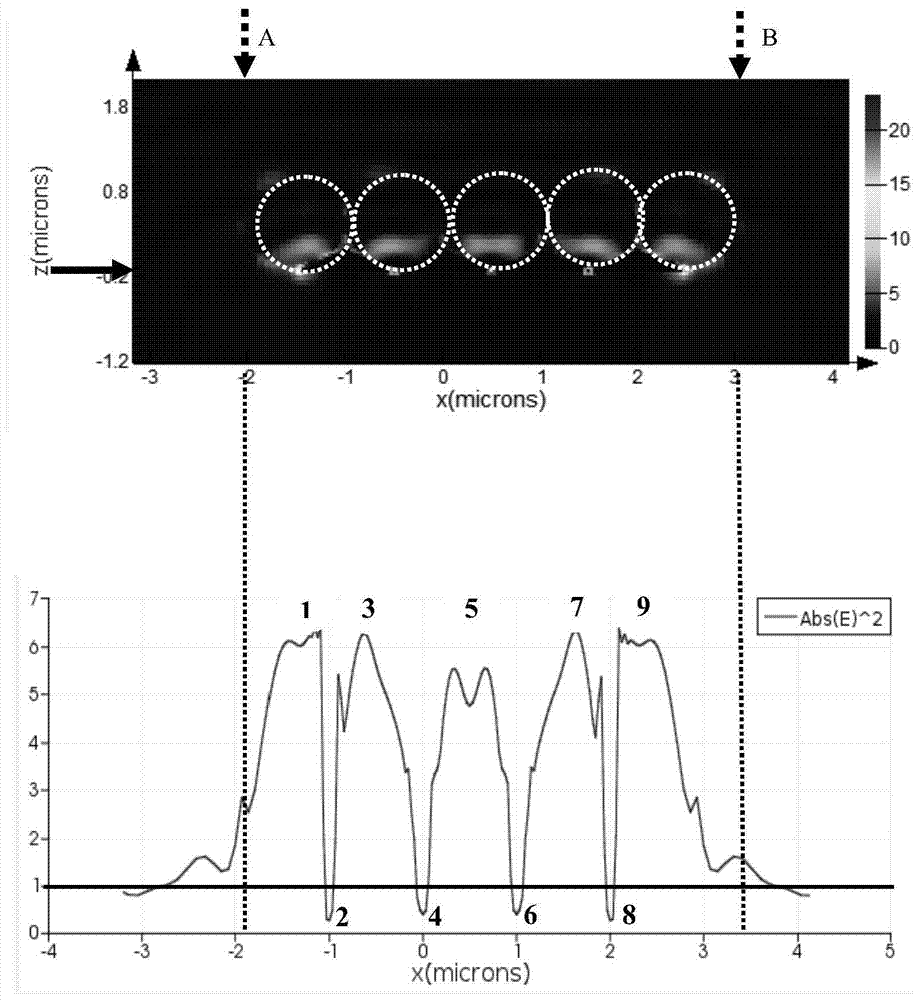

Method used

Image

Examples

preparation example Construction

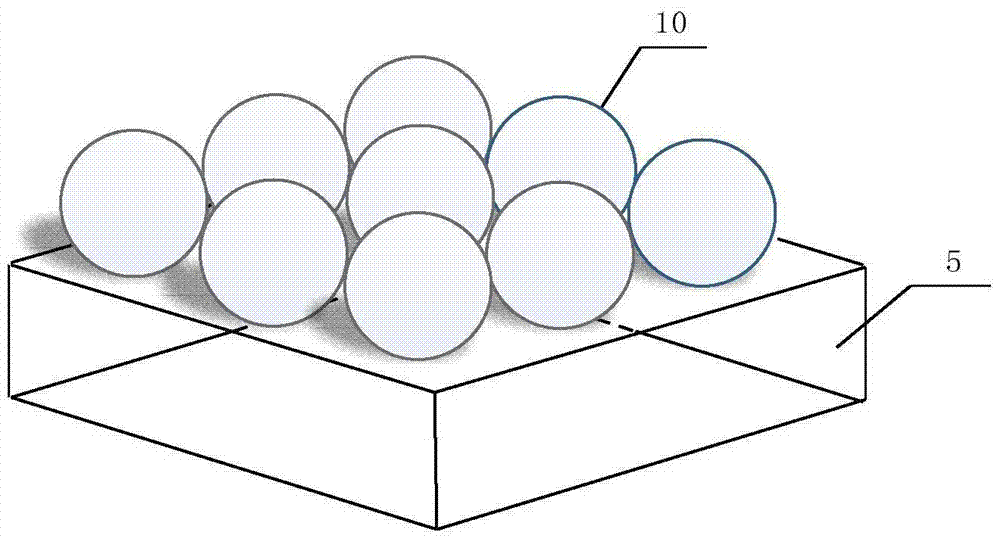

[0048] ③ Preparation of single-layer micro-nanoparticles: In order to obtain an ideal single-layer neatly arranged micro-nanoparticles, the solution of micro-nanoparticles is ultrasonically treated to prepare a suspension of micro-nanoparticles, using Peltier monomers, and connecting electrodes as heat source. Drop the suspension of micro-nano particles on the surface of the glass plate, place it in a dry and ventilated box, tilt the box at a small angle p, and wait for 24-36 hours to dry completely.

[0049] 2) Surface pretreatment of the workpiece to be polished

[0050] Using mechanical methods, use coarse to fine sandpaper to polish the surface of the workpiece to be polished, and then polish the surface with a polishing machine. After cleaning, test the surface roughness microscopically, requiring Ra<1μm.

[0051] 3) The glass plate covers the workpiece to be polished

[0052] Attach the surface of the pretreated workpiece to be polished to the glass surface with micro-...

Embodiment

[0061] according to Figure 5 The process steps shown, first, use 160 mesh, 240 mesh, 600 mesh, 800 mesh, 1000 mesh, 1200 mesh, 1600 mesh, 2000 mesh sandpaper to polish the surface of the workpiece to be polished, polish the surface with a polishing machine, and clean it with alcohol After cleaning, the microscopic test shows that the surface roughness Ra=0.751μm, and the roughness curve is as follows Figure 6 shown.

[0062] To make a glass plate coated with micro-nano particles, first wash the surface of the glass plate with soapy water, ultrasonically treat it with methanol for 10 minutes, then rinse the glass plate with deionized water, and then use nitric acid and water with a volume ratio of 1:3. The solution was soaked for 24 hours, the glass plate was taken out, rinsed with deionized water, and finally washed with N 2 Gas dry the glass plate and save it for later use.

[0063] Select micronanoparticles as SiO 2 , the micro-nanoparticle size diameter R is 500nm, ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com