Pre-laid wet-laid waterproofing membrane with cross-linked reactive layer

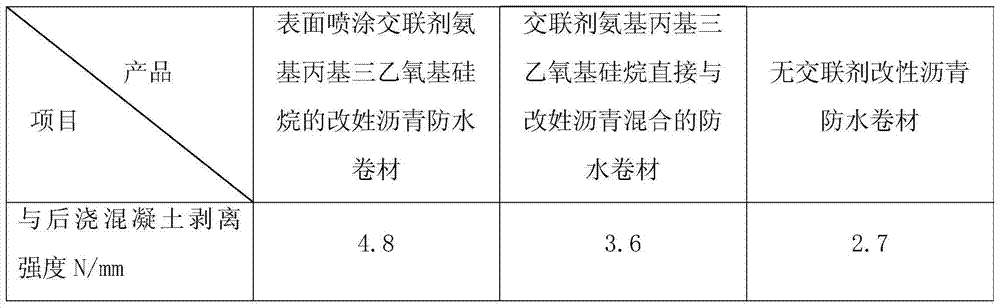

A technology of cross-linking reaction and waterproof membrane, which is applied in the direction of lamination, lamination equipment, layered products, etc., can solve the problems of the addition amount and the adhesion effect not reaching the optimal state, and increase the reactive area , Excellent sealing and waterproof effect, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The structure of the pre-laid wet-laid waterproof membrane is as follows: the first layer is a polyethylene film layer, the second layer is a SBS modified asphalt layer, the third layer is a vinyl triethoxysilane layer, and the bottom layer is a polyethylene isolation film layer .

Embodiment 2

[0037] The structure of the pre-laid wet-laid waterproof membrane is as follows: the first layer is a polyvinyl chloride isolation film layer, the second layer is a tetraisopropyl bis(dioctylphosphite acyloxy) titanate layer, and the third layer is a SBR modified asphalt layer, the fourth layer is polyester fiber cloth, the fifth layer is SBR modified asphalt layer, the sixth layer is aminopropyltriethoxysilane layer, and the bottom layer is PVC isolation film layer.

Embodiment 3

[0039] The structure of the pre-laid wet-laid waterproof membrane is as follows: the first layer is a polyester isolation film layer, the second layer is a vinyl triethoxysilane layer, the third layer is a SBS modified asphalt layer, and the fourth layer is a thermoplastic elastic Body layer, the fifth layer is SBS modified asphalt layer, the sixth layer is vinyl triethoxysilane layer, and the bottom layer is polyester isolation film layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com