Disc-type aerator

An aerator and disc technology, which is applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problem of increasing maintenance workload and economic losses, reducing sewage treatment capacity in sewage treatment plants, and affecting sewage. Treatment efficiency and other issues, to achieve the effect of improving sewage treatment capacity and economic benefits, improving oxygen utilization rate and oxygenation capacity, and good aeration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

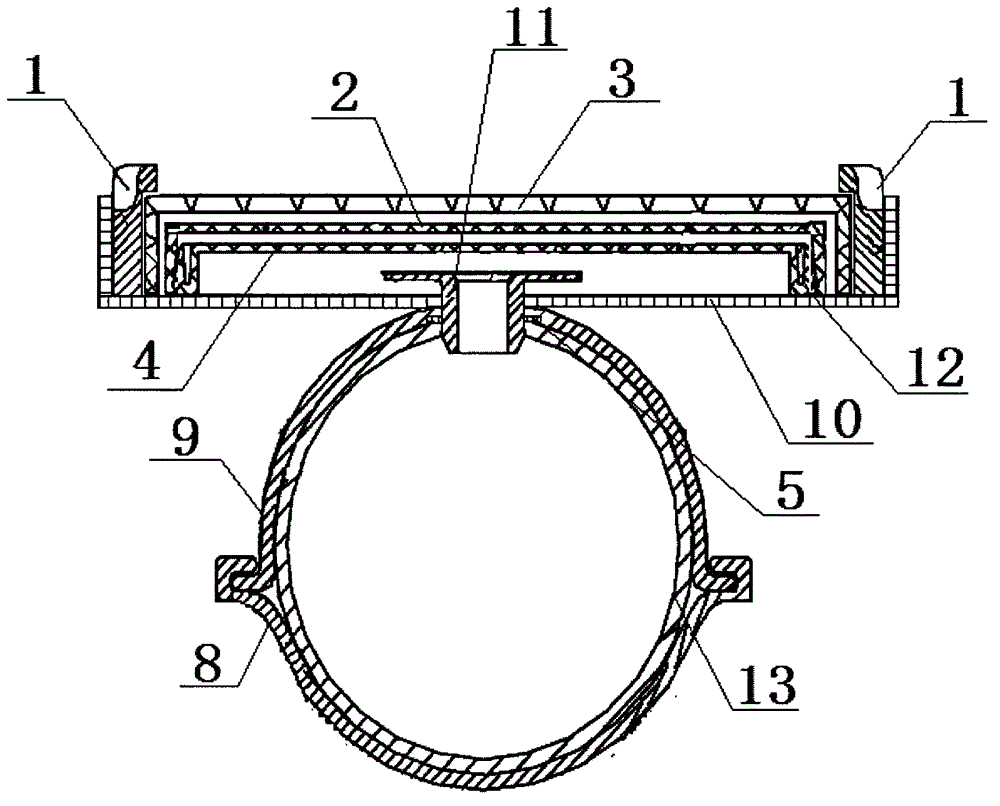

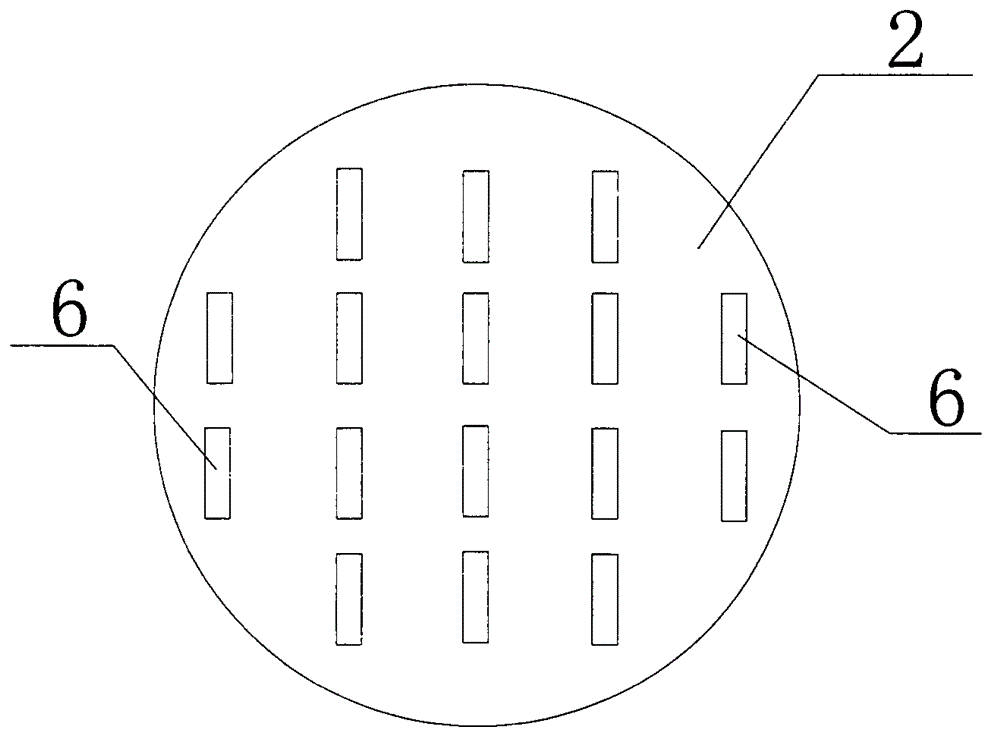

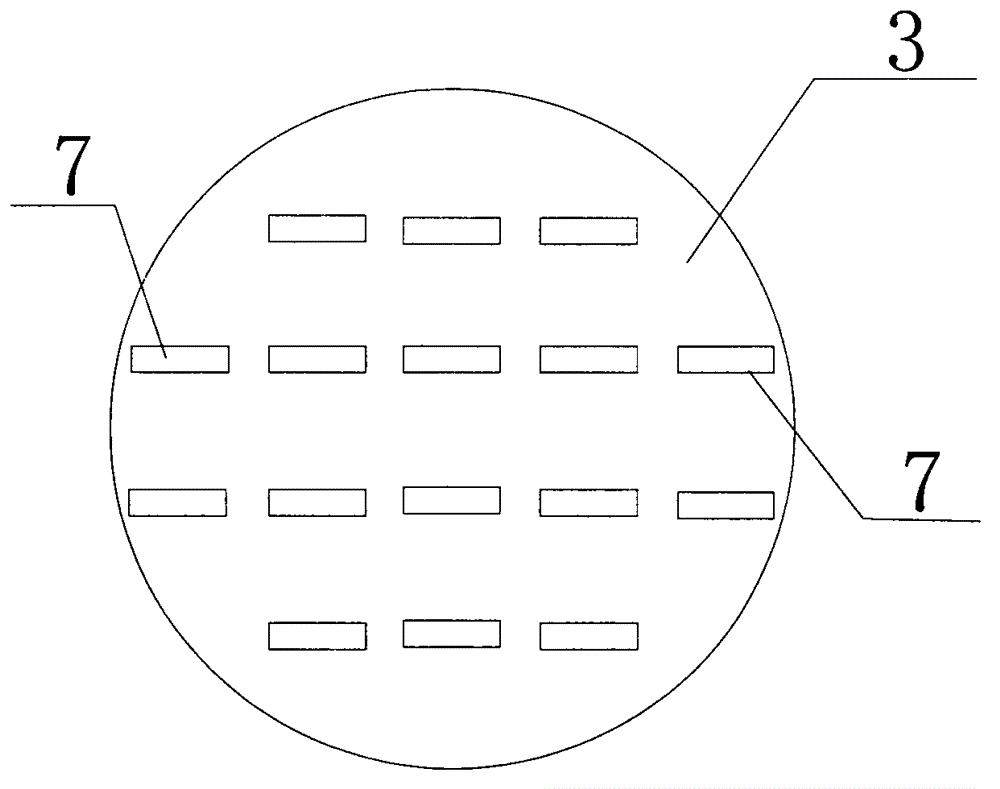

[0028] A disc aerator provided in this embodiment has a structure such as Figure 1-3 As shown, it includes a screw gland 1, a diaphragm, a diversion support plate 4 and a base that are sequentially provided from top to bottom, and a check valve 5 integrating a hole valve is also provided between the diversion support plate 4 and the base. The diaphragm is made up of the first diaphragm 2 and the second diaphragm 3 arranged on the first diaphragm 2, the first diaphragm 2 has a plurality of strip-shaped first micropores 6, the second diaphragm 3 There are a plurality of strip-shaped second microholes 7, the first microholes 6 and the second microholes 7 are arranged in a staggered manner up and down, and their midpoints are on the same straight line; the bottom of the base is also provided with an inverted saddle wedge plate 8.

[0029] In this embodiment, the first diaphragm 2 is EPDM rubber, the second diaphragm 3 is urethane, the second diaphragm 3 is covered on the first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com