Production method for ethylenediamine through catalytic ammoniation process

A technology of ethylenediamine and ethanolamine, which is applied in chemical instruments and methods, preparation of organic compounds, purification/separation of amino compounds, etc., can solve the problems of low purity of ethylenediamine and piperazine products, difficulty in separation of crystal water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

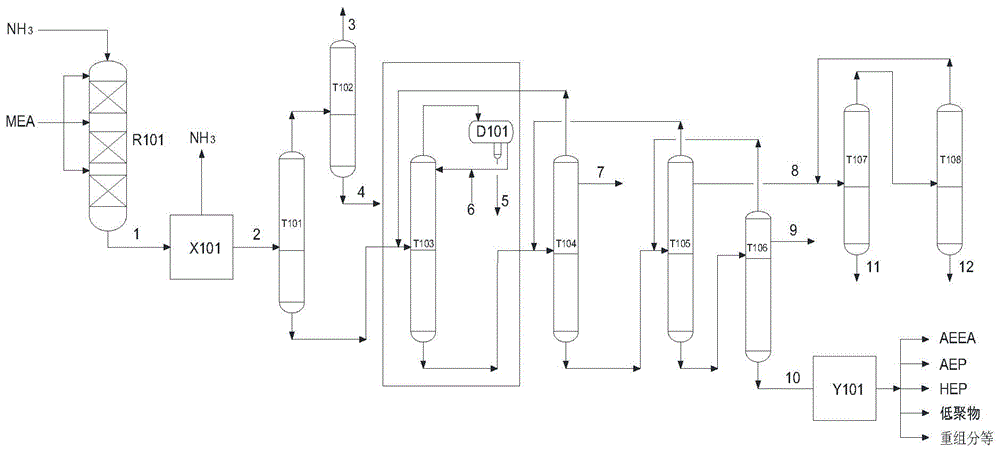

[0045] Process flow chart such as figure 1 As shown, liquid ammonia and MEA enter R101 after being heated, and MEA is divided into one or more strands. The reaction product 1 enters the ammonia recovery system X101 to recover ammonia. After the ammonia is recovered, the mixture 2 containing MEA enters the initial distillation tower T101 to separate EDA and free water. EDA and free water enter the EDA tower T102, pressurized rectification, the waste water 3 at the top of the tower goes to post-treatment, and the EDA product 4 is obtained from the bottom of the tower. The liquid in the primary distillation tower T101 enters the azeotropic distillation tower T103, the entrainer replenishment line 6 is connected to the return line at the top of the azeotropic distillation tower T103, the waste water 5 goes to post-treatment, and the liquid in the bottom of the tower goes to the PIP tower T104. The side line discharge 7 at the top of the PIP tower T104 is the PIP product, and the ...

Embodiment 2

[0056] Embodiment is identical with embodiment 1.

[0057] T101, T103~T108 are all filled with 500m 2 / m 3 Metal mesh corrugated packing with specific surface area. T102 loading 500m 2 / m 3 Specific surface area corrugated wire mesh packing or valve tray.

[0058] The operating pressure of the initial distillation column T101 is 0.40MPaA.

[0059] The operating pressure of the EDA tower T102 is 0.52MPaA, the waste water produced at the top of the tower goes to post-treatment, the purity of the EDA product in the tower kettle is ≥99.9wt%, the organic impurities are ≤0.05wt%, the water content is ≤0.05wt%, and the APHA is ≤15.

[0060] The operating pressure of the azeotropic distillation column T103 is 0.07MPaA.

[0061]The operating pressure of the PIP tower T104 is 0.03MPaA, the top of the tower is taken back to the azeotropic distillation tower T103, and the PIP product is taken from the fifth theoretical plate below the top of the tower. The purity of the PIP product ...

Embodiment 3

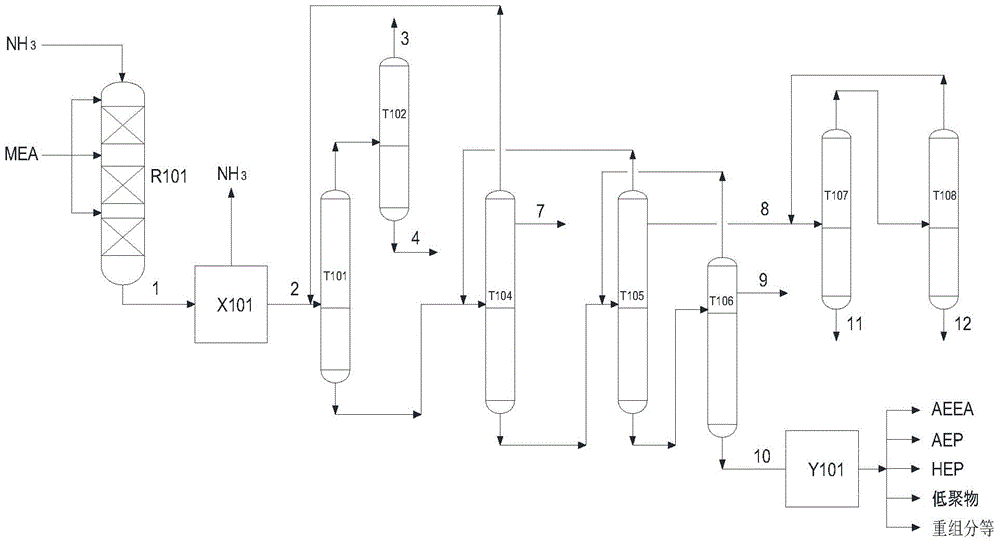

[0067] Embodiment is identical with embodiment 1, and process flow chart is as figure 2 shown.

[0068] figure 1 The azeotropic distillation column in the dotted line box is cancelled, the T101 column kettle stream directly enters the T104 column, the top of the T104 column is extracted and returned to the T101 column, and the hexahydrate PIP product is extracted from the fifth theoretical plate below the top of the T104 column.

[0069] T101, T104~T108 are all filled with 550m 2 / m 3 Metal mesh corrugated packing with specific surface area. T102 loading 550m 2 / m 3 Specific surface area corrugated wire mesh packing or valve tray.

[0070] The operating pressure of the initial distillation column T101 is 0.45MPaA.

[0071] The operating pressure of the EDA tower T102 is 0.55MPaA, the waste water produced at the top of the tower goes to post-treatment, the purity of the EDA product in the tower kettle is ≥99.9wt%, the organic impurities are ≤0.05wt%, the water content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com