Crosslinking agent, preparation method and application thereof, and CO2-responding polymer

A technology of cross-linking agent and polymer, applied in the field of polymer chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

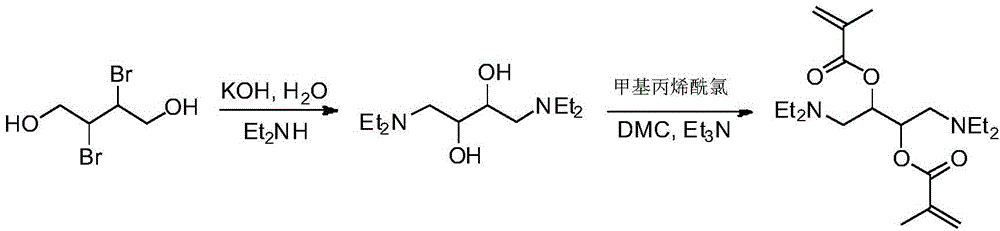

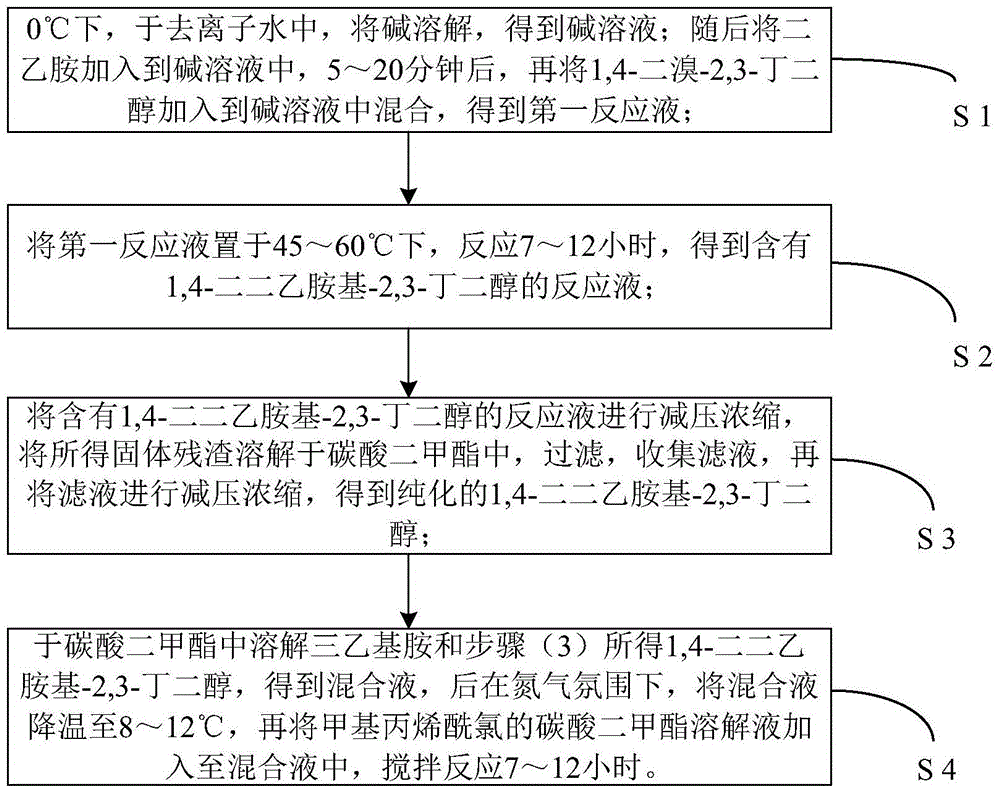

[0041] figure 2 A preferred embodiment of the preparation method of the present invention is shown. from figure 2 As can be seen, the preparation method mainly includes four steps:

[0042]First, dissolve the alkali in deionized water at 0°C to obtain an alkali solution; then add diethylamine to the alkali solution, and after 5 to 20 minutes, add 1,4-dibromo-2,3-butyl Diol is added into the alkali solution and mixed to obtain the first reaction liquid. For the mixing mentioned in the preparation method, conventional mixing methods, such as stirring, can be used to uniformly dissolve 1,4-dibromo-2,3-butanediol. The present invention has no special limitation on the source of 1,4-dibromo-2,3-butanediol and diethylamine, and adopts 1,4-dibromo-2,3-butanediol and Diethylamine is sufficient, and if it can be commercially available, it can also be prepared by itself using the technical scheme for preparing 1,4-dibromo-2,3-butanediol and diethylamine well known to those skilled...

Embodiment 1

[0060] Embodiment 1 of the present invention provides a crosslinking agent, which is prepared according to the following steps:

[0061] (1) Dissolve KOH (8.75g, 0.151mol) into water (35mL) in deionized water at 0°C to obtain an alkaline solution; then diethylamine (25mL, 0.242mol) was added to the alkaline solution, After 5 to 20 minutes, add 1,4-dibromo-2,3-butanediol (15.1 g, 0.0605 mmol) into the alkali solution and mix to obtain the first reaction solution;

[0062] (2) Put the first reaction solution at 50°C and react for 7 to 12 hours to obtain a reaction solution containing 1,4-diethylamino-2,3-butanediol;

[0063] (3) Concentrate the reaction solution containing 1,4-diethylamino-2,3-butanediol under reduced pressure, dissolve the resulting solid residue in dimethyl carbonate (50ml), filter, and collect the filtrate, The filtrate was then concentrated under reduced pressure to obtain purified 1,4-diethylamino-2,3-butanediol (7.62g, 54%);

[0064] (4) Dissolve triethy...

Embodiment 2

[0072] Embodiment 2 of the present invention provides a crosslinking agent, which is prepared according to the following steps:

[0073] (1) Dissolve KOH (5.25g, 0.0906mol) into water (35mL) in deionized water at 0°C to obtain an alkaline solution; then add diethylamine (12.5mL, 0.121mol) to the alkaline solution , after 5 to 20 minutes, add 1,4-dibromo-2,3-butanediol (15.1 g, 0.0605 mmol) into the alkali solution and mix to obtain the first reaction solution;

[0074] (2) Put the first reaction solution at 45°C and react for 7 to 12 hours to obtain a reaction solution containing 1,4-diethylamino-2,3-butanediol;

[0075] (3) Concentrate the reaction solution containing 1,4-diethylamino-2,3-butanediol under reduced pressure, dissolve the resulting solid residue in dimethyl carbonate (50ml), filter, and collect the filtrate, Then the filtrate was concentrated under reduced pressure to obtain purified 1,4-diethylamino-2,3-butanediol (6.72 g);

[0076] (4) Dissolve triethylamine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com