A kind of electroplating solution and electroplating method for electrodepositing Invar alloy with alkaline solution of ferric iron system

A technology of alkaline solution and Invar alloy, which is applied in the field of electrodeposited alloys, can solve the problems of poor stability of electroplating solution and insufficient overpotential of electrodeposition, and achieve the effects of good stability, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

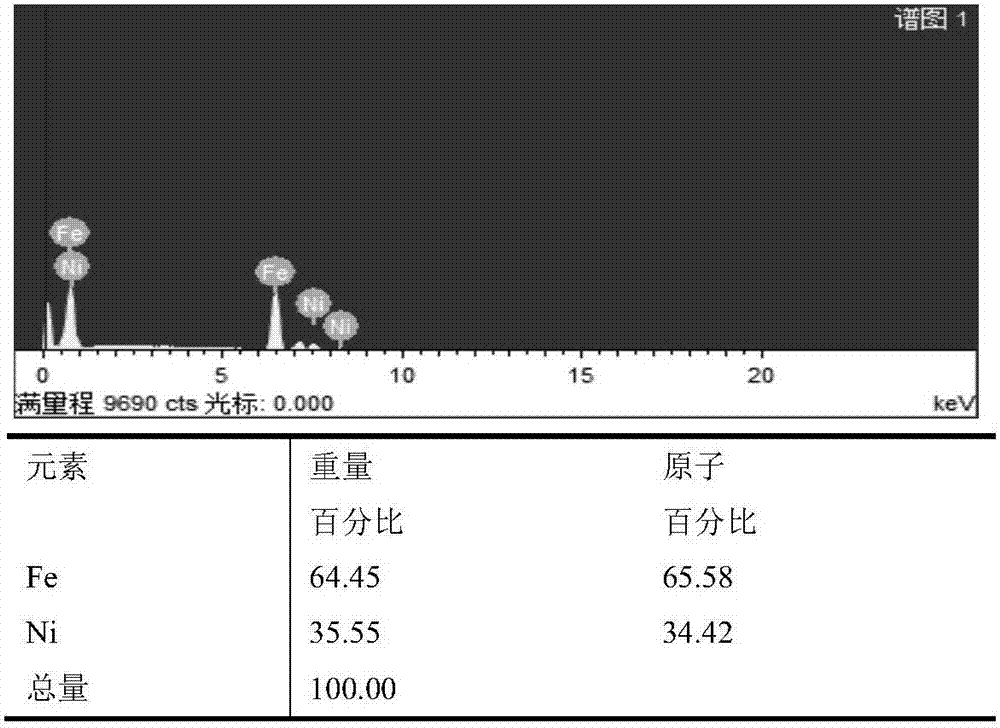

[0044] The specific preparation process of the electroplating solution is (take the preparation of one liter as an example):

[0045] ① Accurately weigh the primary complexing agent (120-180g), secondary complexing agent (30-60g), buffer (20-40g), add 500-600mL deionized water, stir and dissolve evenly;

[0046] ② Add ferric salt (15-45g) to ① and stir to dissolve evenly;

[0047] ③ Add nickel salt (25-65g) to ② and stir to dissolve evenly;

[0048] ④Continue to add 0.1-5.0g of additives and 1-20mg of wetting agent to ③ and stir to dissolve evenly;

[0049] ⑤ with 10% NaOH solution and 10% H 2 SO 4 The pH value of the solution was adjusted to be in the range of 8.5-11.5.

[0050] ⑥ Add an appropriate amount of deionized water to a volume of 1 L and stir well.

[0051] The process of using the electroplating solution is:

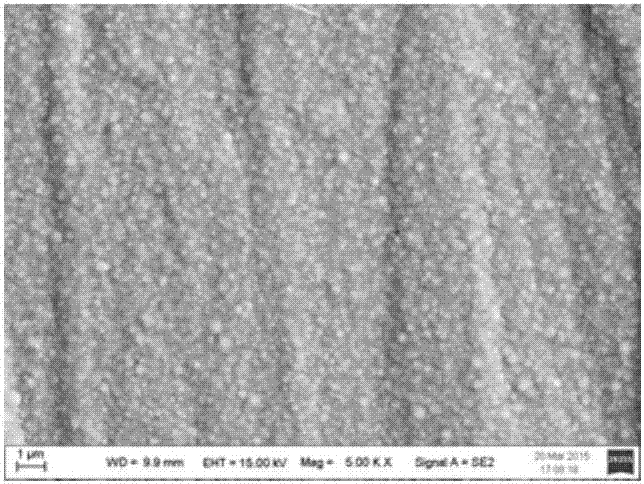

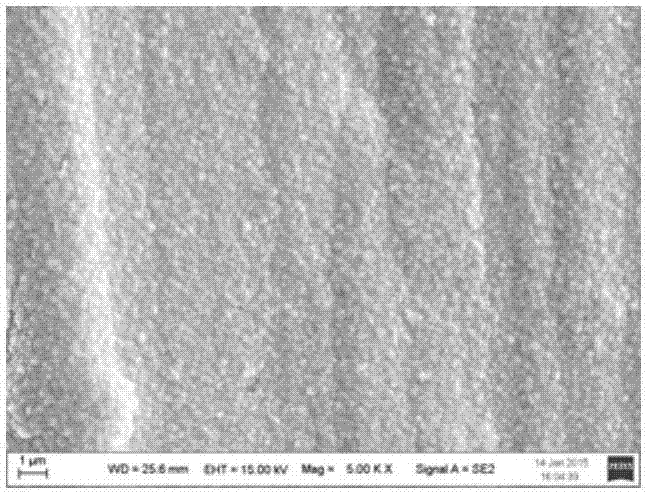

[0052] Pour the above prepared electroplating solution into the plating tank, heat to 40-65°C, use nickel plate or Invar alloy plate (Invar 36) as anod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com