Combined lithium ion battery and manufacturing method thereof

A technology of lithium-ion batteries and manufacturing methods, which is applied in the field of combined lithium-ion batteries, can solve problems such as uneven internal heat distribution, uneven current density distribution, and small capacity of single batteries, so as to ensure electrochemical performance and heat easily Dispersion, the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

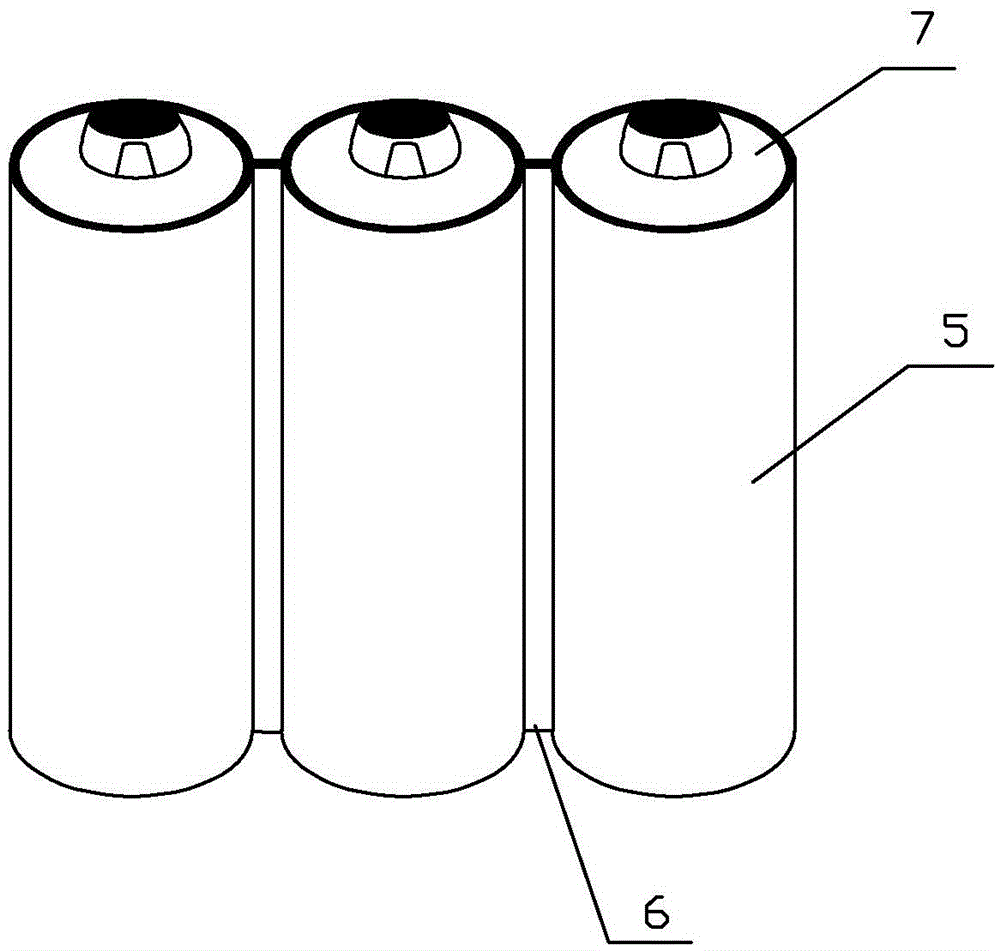

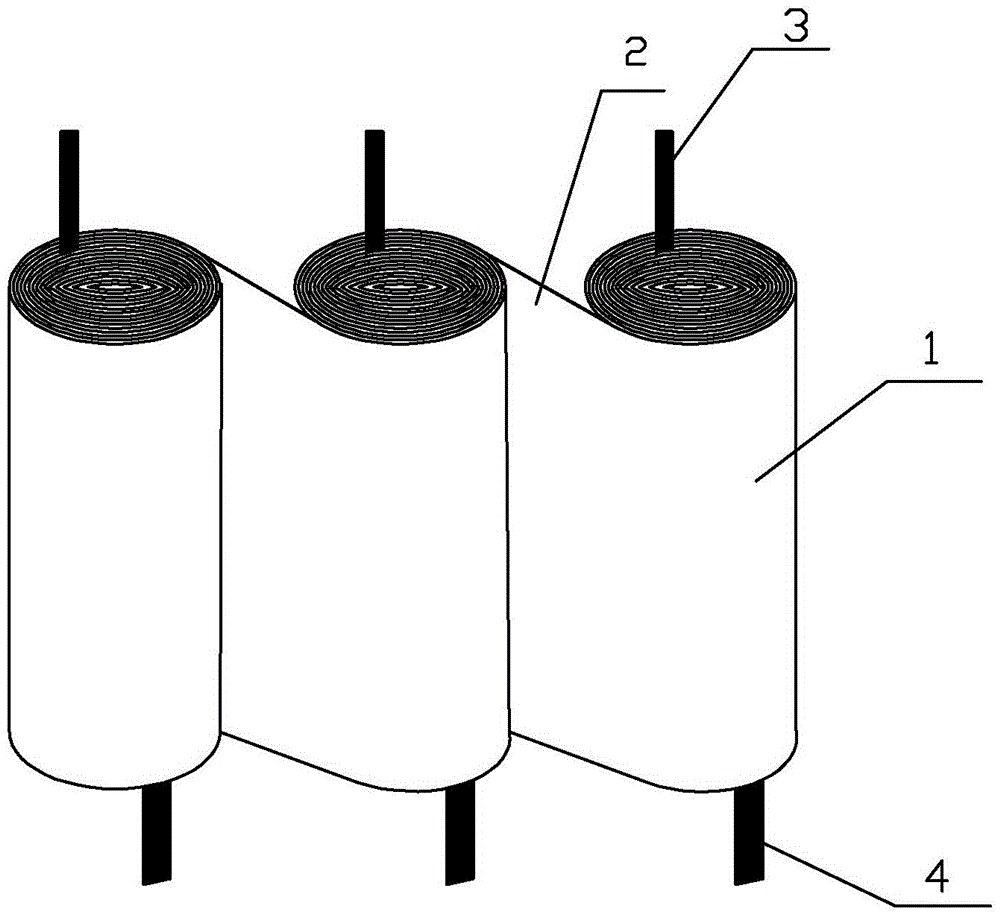

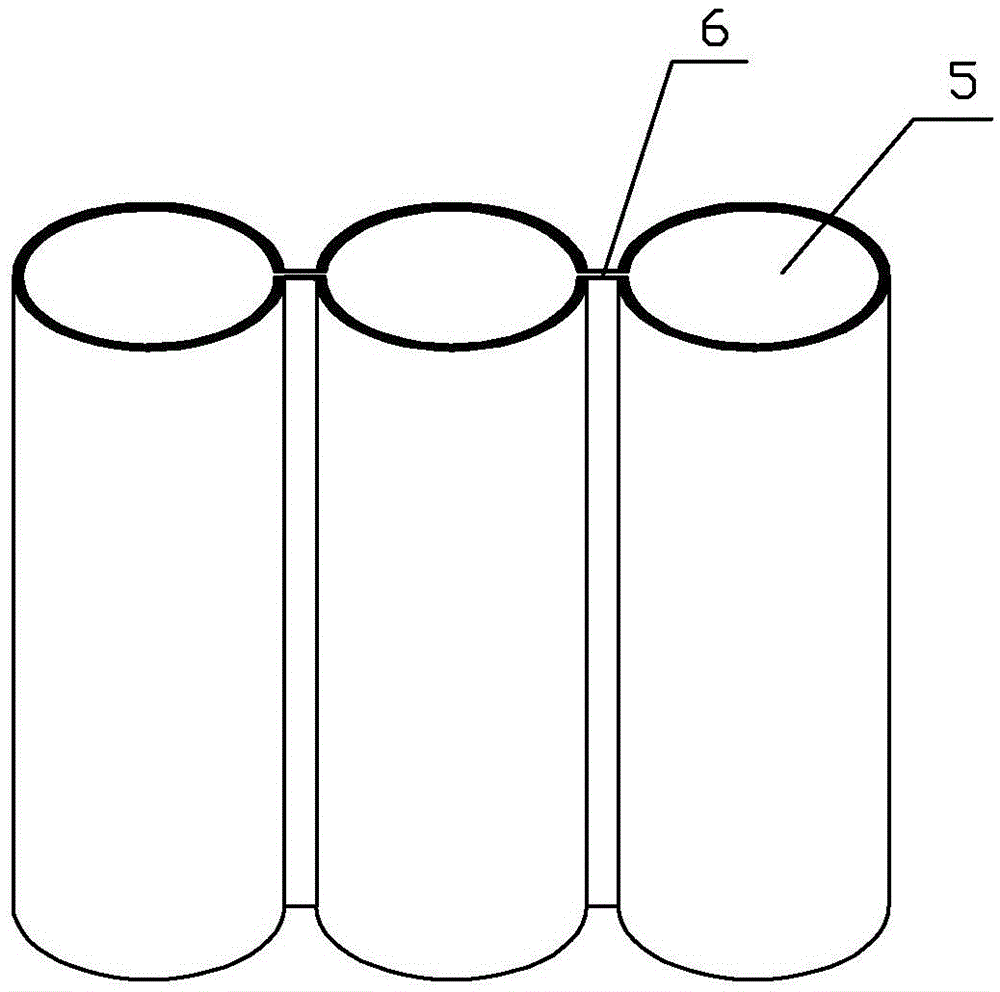

[0037] Embodiment: the combined lithium ion battery of the present embodiment, as figure 1 , figure 2 As shown, it includes three electric cores 1, a shell formed by connecting three cylindrical shells 5, and a cap formed by connecting three circular caps 7. The three electric cores 1 are wound on the electric The pole piece 2 on the core 1 is directly connected, and the two ends of each cell 1 are respectively connected with a positive pole tab 3 and a negative pole tab 4, such as image 3 As shown, three barrel-shaped shells 5 are arranged in a row, and a narrow channel 6 with a closed bottom is connected between two adjacent barrel-shaped shells 5, and the barrel-shaped shells on both sides of the channel 6 5 connected, the height of the channel 6 is consistent with the height of the barrel-shaped casing 5, the axis of the barrel-shaped casing 5 and the centerline of the channel 6 are on the same plane, and the three cells 1 are located in three corresponding one-to-one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com