A spiral ring full road interchange system

A manufacturing method and additive technology, which are applied in papermaking, reinforcing agent addition, textile and papermaking, etc., can solve the problems of improved water drainage, weak flocculation, insufficient expansion of molecular structure, etc., and achieve improved retention rate and improved drainage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

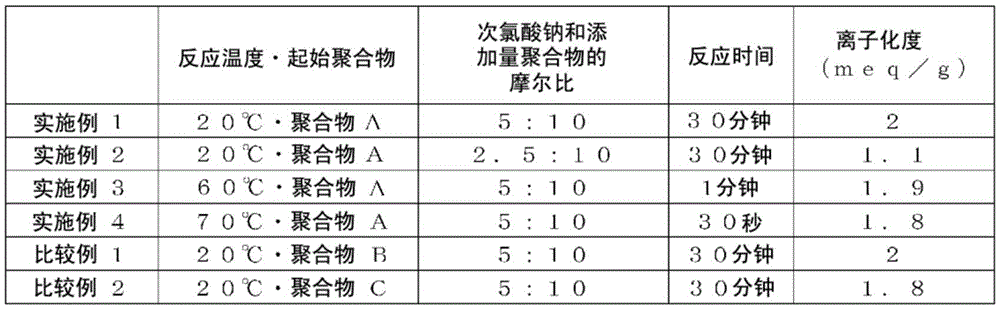

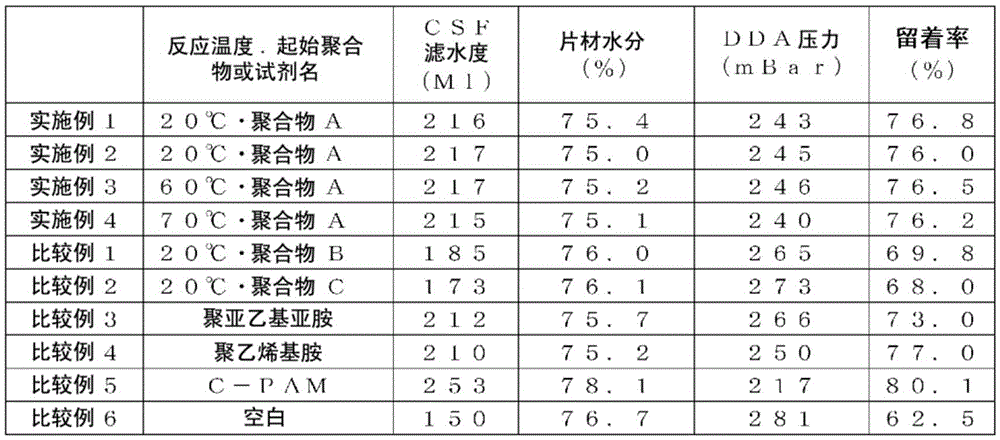

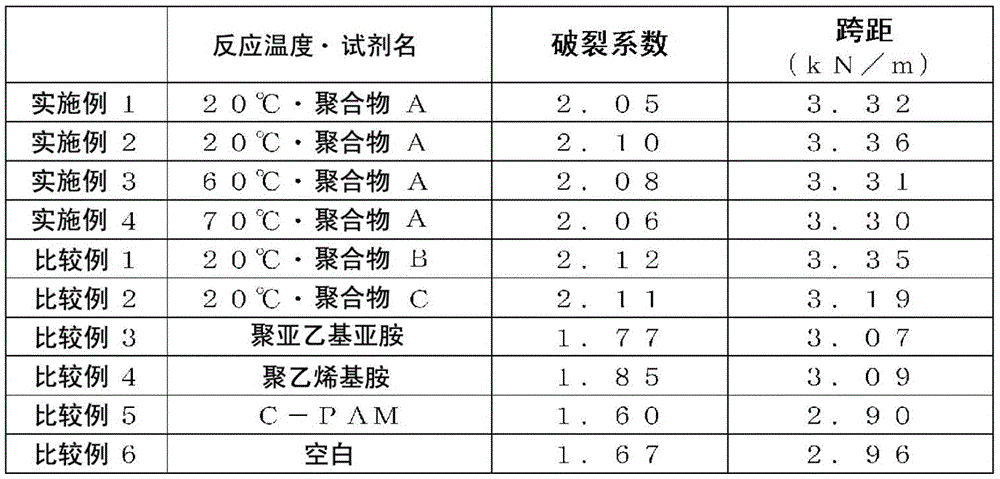

Examples

Embodiment

[0056] (Polymer A)

[0057] In a four-neck flask equipped with a stirrer and a temperature sensor, 198 g of acrylamide (AAM) powder and 793 g of ion-exchanged water were added, and the weight of the monomer was 20% of the whole, and the total weight was adjusted to 990 g. Next, the temperature was adjusted to 20° C., and nitrogen substitution was performed. Add 1ml of ammonium persulfate 0.1% aqueous solution and 0.3g of 2,2'-azobis-2-amidinopropane hydrochloride aqueous solution to the adjusted solution, and then continue nitrogen replacement, after about 5 minutes Start to aggregate. The temperature was slowly raised to about 65°C, and the polymerization was completed in 5 hours.

[0058] During polymerization, the content became highly viscous and stirring became difficult, so stirring was stopped halfway. After the polymerization was terminated, the contents were taken out. The polymer has an intrinsic viscosity of about 14.8 dl / g. In addition, a very high-purity non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com