Integrated dual-stage elastic fiber filter material and flat ceramic membrane coupling bioreactor

An elastic fiber, ceramic membrane technology, applied in the field of sewage treatment equipment manufacturing, can solve the problems of difficult industrial reuse water treatment, high treatment difficulty, large area of water treatment structures, etc. Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

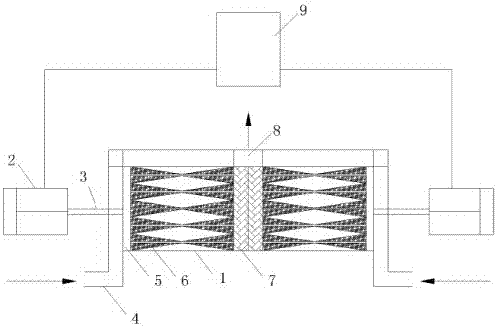

[0015] The device consists of a main device 1, a motor 2, a rotating shaft 3, an inlet channel 4, a closable perforated flower wall 5, an elastic fiber filter material 6, a flat ceramic membrane 7, an outlet channel 8, and a PLC control cabinet 9. During specific implementation, the water flow first enters from the water inlet channel 4 on one side, and enters the main device 1 through the closable perforated flower wall 5. At this time, the perforation of the closable perforated flower wall 5 is in an open state; After filling one side, stop the water intake and stagnate for half an hour, then the motor 2 on the water intake side drives the rotating shaft 3 on the same side to push the closable perforated flower wall 5 on the same side to compress, at this time, the perforated flower wall 5 can be closed and all the perforations are closed at the same time to form a steel plate. The perforated flower wall 5 can be closed to compress the elastic fiber filter material 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com