Drinking water terminal sterilization water purifier

A technology for water purifiers and drinking water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of excessive bacteria in the effluent, rising manufacturing costs, and increased power consumption, etc. problems, to achieve the effect of reducing heavy metal ions, long service life and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

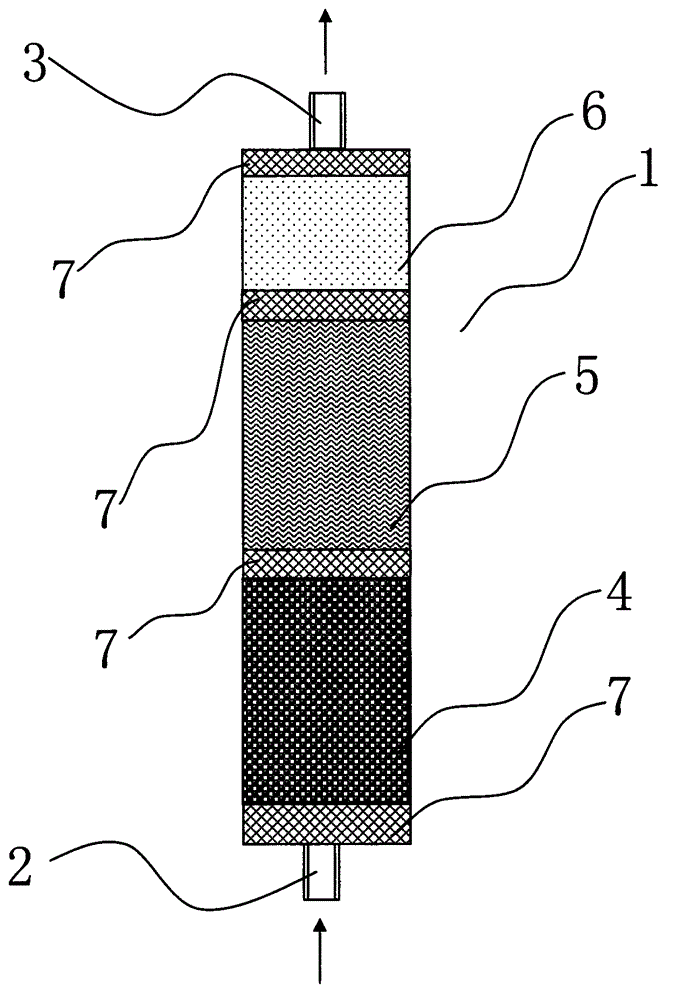

[0015] Such as figure 1 As shown, a terminal sterilization filter for drinking water includes a pipe body 1 and a water inlet 2 and a water outlet 3 arranged at both ends of the pipe body. The pipe body 1 is provided with sterilization Layer 4, water purification layer 5 and heavy metal ion removal layer 6.

[0016] In the present invention, in order to remove chlorine, suspended solids, silt particles and impurities in the water at the filter water inlet 2 and further ensure the cleanness of the water at the filter outlet 3, the sterilizing layer 4 and the water purification layer are located in the pipe body 1. The upstream side and the downstream side of the layer 5 and the heavy metal ion removal layer 6 are provided with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com