Method for recovering phenylbutazone from phenylbutazone refined product mother solution waste residues

A technology of phenylbutazone and mother liquor, which is applied in the field of medicine and chemical industry, can solve the problems of old oil residue, easy decomposition of phenylbutazone, destruction of phenylbutazone, etc., and achieves improved productivity, obvious economic and environmental benefits, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

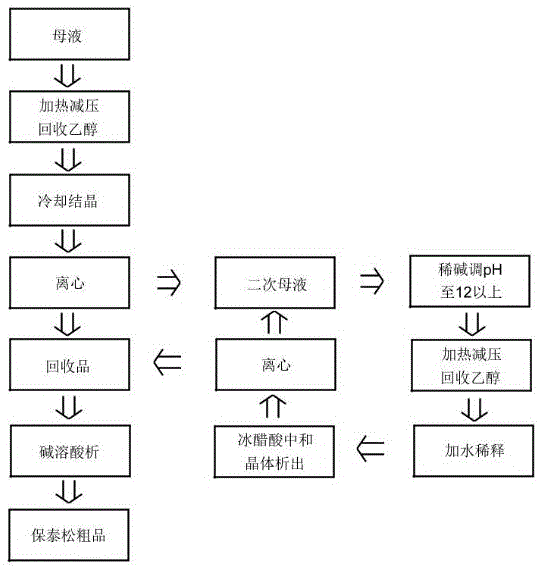

[0023] Such as figure 1 Shown, the method for reclaiming butyl pine from butyl pine fine-art mother liquor waste residue of the present invention may further comprise the steps:

[0024] (1) Take the 8wt% phenylbutazone fine mother liquor and place it in the recycling tank, heat and reduce pressure in a water bath to recover ethanol, control the temperature of the water bath below 40°C, and keep the vacuum at -0.098MPa. The concentrated hydraulic pressure after recovering ethanol is put into cold crystallization In the pot, cool to 5°C to crystallize, and then centrifuge to obtain the recovered product of phenylbutazone and the secondary mother liquor, and the secondary mother liquor is used for further recovery of phenylbutazone;

[0025] (2) Adjust the pH of the secondary mother liquor obtained in step (1) to above 12 with NaOH with a mass concentration of 5%, and then heat and reduce pressure in a water bath to recover ethanol. The concentrated solution is diluted with wat...

Embodiment 2

[0028] Such as figure 1 Shown, the method for reclaiming butyl pine from butyl pine fine-art mother liquor waste residue of the present invention may further comprise the steps:

[0029] (1) Take 2wt% phenylbutazone fine-quality mother liquor and put it in the recovery tank, heat and reduce pressure in a water bath to recover ethanol, control the temperature of the water bath below 40°C, and keep the vacuum at -0.09MPa. The concentrated hydraulic pressure after recovering ethanol is put into cold crystallization In the pot, cool to 0°C to crystallize, and then centrifuge to obtain the recovered product of phenylbutazone and the secondary mother liquor, where the secondary mother liquor is used for further recovery of phenylbutazone;

[0030] (2) Adjust the pH of the secondary mother liquor obtained in step (1) to above 12 with NaOH with a mass concentration of 5%, and recover ethanol by heating in a water bath under reduced pressure. The temperature of the water bath is below ...

Embodiment 3

[0033] Such as figure 1 Shown, the method for reclaiming butyl pine from butyl pine fine-art mother liquor waste residue of the present invention may further comprise the steps:

[0034] (1) Take 10wt% phenylbutazone fine-quality mother liquor and put it in the recovery tank, heat and reduce pressure in a water bath to recover ethanol, control the temperature of the water bath below 40°C, and keep the vacuum at -0.094MPa, and the concentrated hydraulic pressure after recovering ethanol is put into cold crystallization In the pot, cool to 3°C to crystallize, and then centrifuge to obtain the recycled phenylbutazone and the secondary mother liquor, where the secondary mother liquor is used for further recovery of phenylbutazone;

[0035] (2) Adjust the pH of the secondary mother liquor obtained in step (1) to above 12 with NaOH with a mass concentration of 5%, and then heat and reduce pressure in a water bath to recover ethanol. The concentrated solution is diluted with water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com