A kind of solar heat storage material and preparation method thereof

A technology of heat storage materials and solar energy, applied in the field of solar heat storage materials and preparation, to achieve the effects of improving heat storage capacity, simple processing technology, and reducing application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

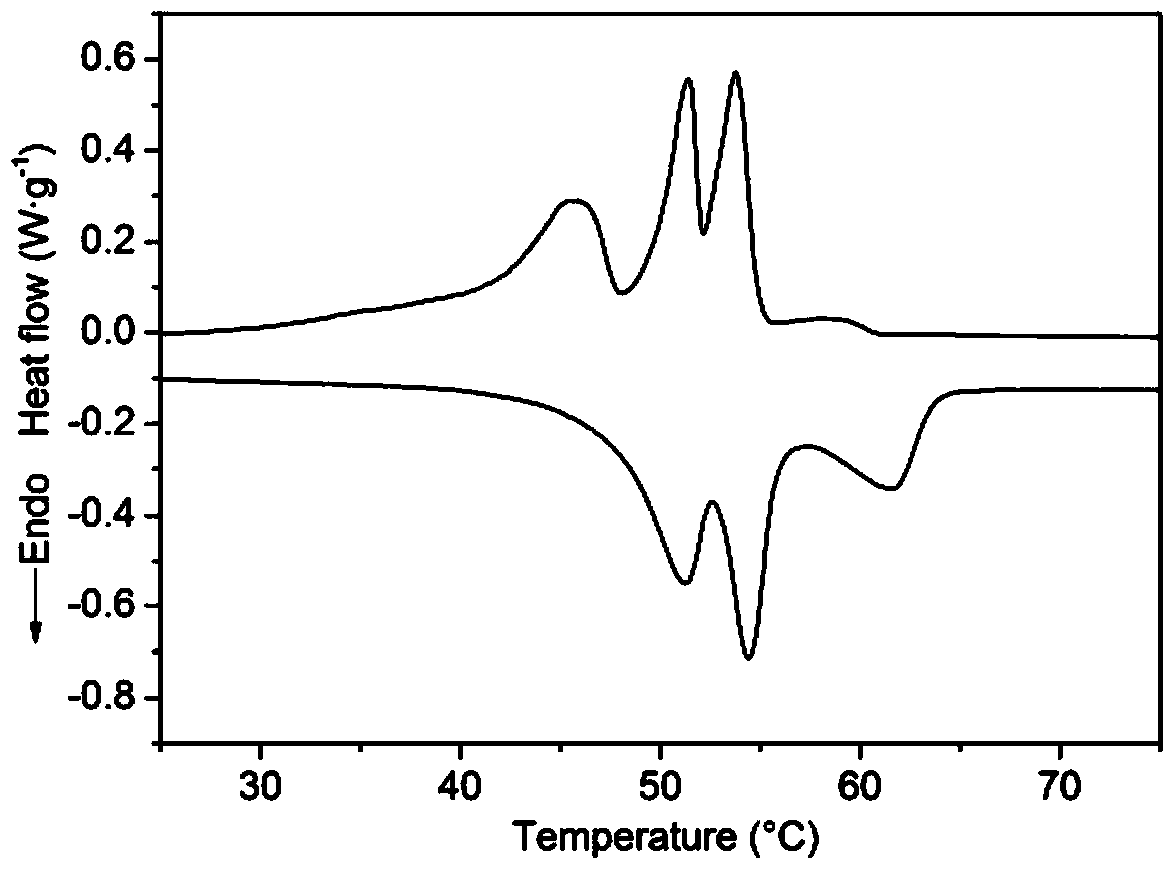

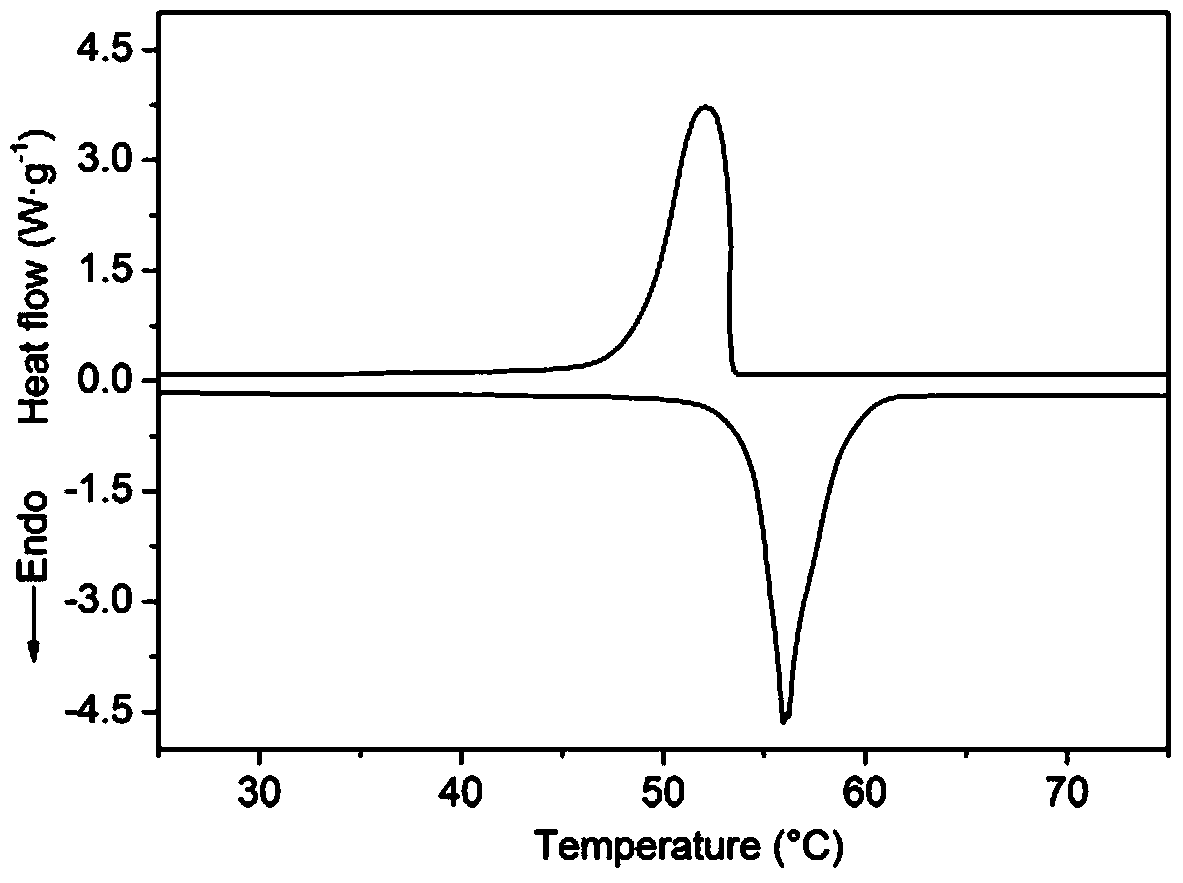

[0028] Weigh 50g of silica sol with a mass fraction of 30% of silica, add 97g of deionized water to dilute, add 2.5mL of silane coupling agent, and stir at 30°C for 14h to obtain a mixed solution; the content of graphene oxide is measured to be 3mg / Add 50 mL of graphene oxide solution into the mixed solution slowly, stir evenly, dry at 50°C, and then bake at 700°C for 3 hours in an argon atmosphere to obtain graphene with a mass ratio of graphene to silicon dioxide of 1:100. - Nano-silica composite material; Weigh 3.0g of stearic acid into a conical flask equipped with a vacuum device, then pour 7.0g of graphene-nano-silica composite material, and vacuum the container to -0.05MPa Finally, place it in a heating type ultrasonic cleaner at 80°C for 40 minutes, stop vacuuming, and return the air to the container. After ultrasonic treatment for 5 minutes, take out the mixture in the container and cool it down to obtain a solar heat storage material. Using TAinstruments DSC Q2000 t...

Embodiment 2

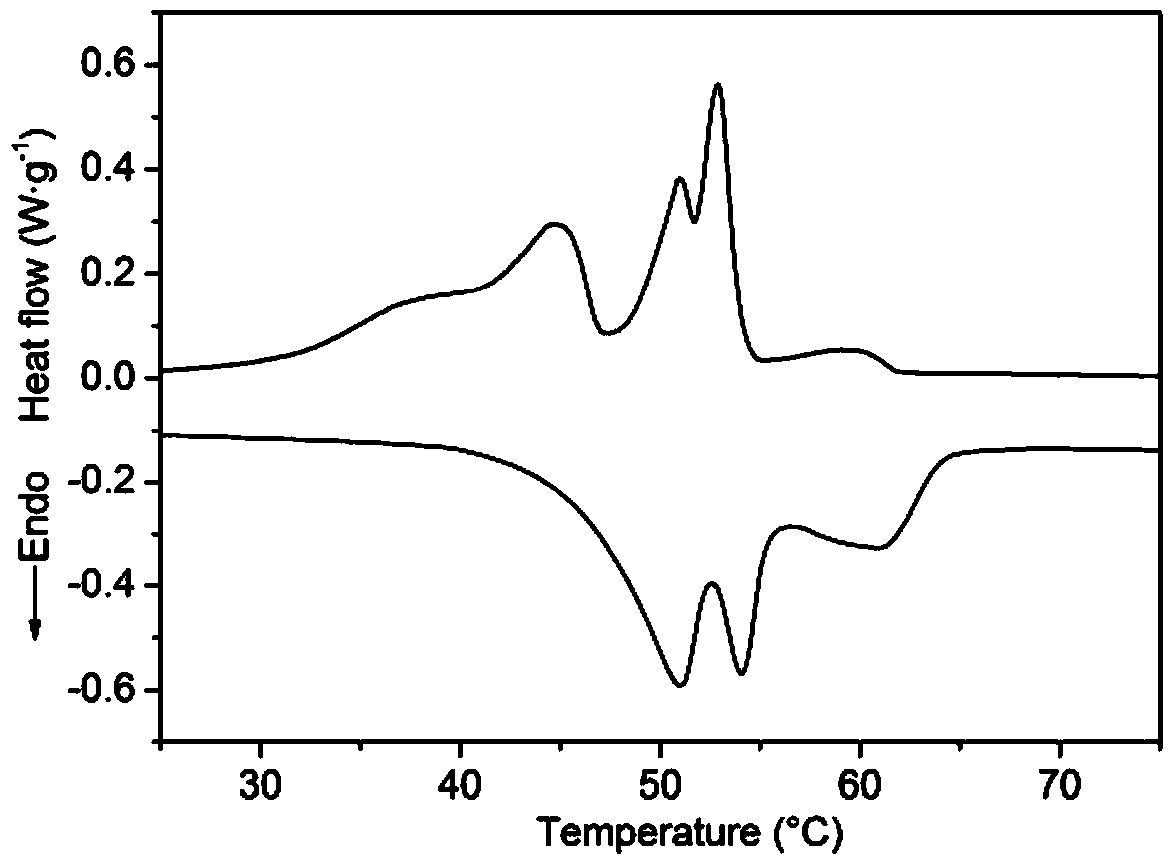

[0030] Weigh 50g of silica sol with a mass fraction of silica of 30%, add 97g of deionized water to dilute, add 2.5mL of silane coupling agent, and stir at 45°C for 10h to obtain a mixed solution; the content of graphene oxide is measured to be 3mg / Add 250 mL of graphene oxide solution into the mixed solution slowly, stir evenly, dry at 60°C, and then bake at 800°C for 2 hours under nitrogen atmosphere to obtain graphene- Nano-silica composite material; Weigh 3.0g of stearic acid into a conical flask equipped with a vacuum device, then pour 7.0g of graphene-nano-silica composite material, and vacuum the container to -0.05MPa , placed in a heating type ultrasonic cleaner at 80°C for 40 minutes, stop vacuuming, return the air to the container, after ultrasonic treatment for 5 minutes, take out the mixture in the container, cool it down, and obtain a solar heat storage material. Using TAinstruments DSC Q2000 to test the heat storage behavior of the material (the latent heat of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| endothermic temperature | aaaaa | aaaaa |

| endothermic temperature | aaaaa | aaaaa |

| exothermic temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com