System and process for microalgae cultivation by means of chemical-looping combustion CO2 and ash

A technology of chemical chain combustion and CO2, applied in biochemical equipment and methods, combustion equipment, solid fuel combustion, etc., can solve the problems of complex flue gas treatment process, high cost, environmental damage, etc. Speed and quality, the effect of promoting cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

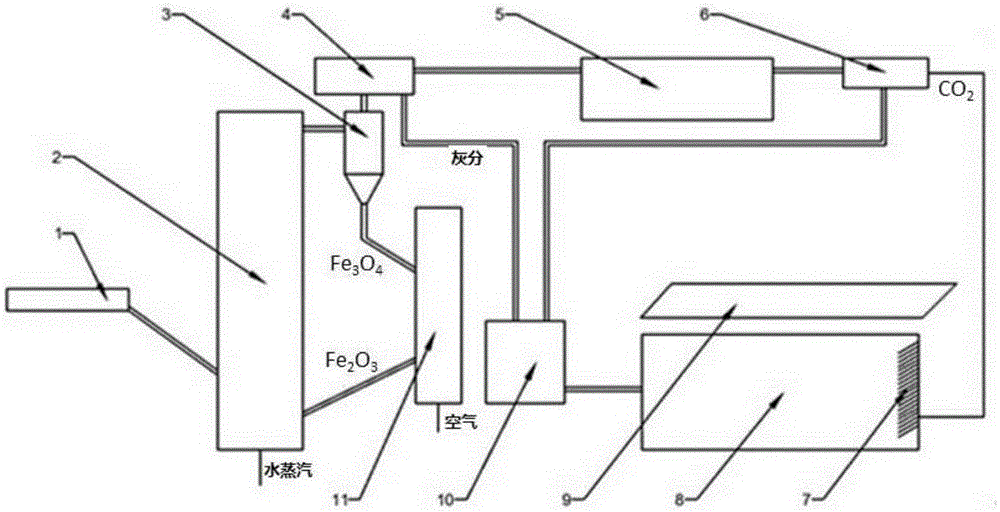

[0032] A method for burning CO using chemical looping 2 As well as the process and system for cultivating microalgae with ash, in the chemical looping combustion device, the combustion reactor adopts a fast fluidized bed, the air reactor adopts a bubbling fluidized bed, and the oxygen carrier is Fe 2 o 3 / Fe 3 O4, the cyclone separator separates the oxygen carrier, flue gas and ash, the oxygen carrier enters the air reactor, and after the reaction occurs, it is sent back to the combustion reactor by overflow. The separated flue gas and ash enter the dust collector to collect the separated combustion ash; the flue gas enters the heat exchanger to provide heat to the external device, and then enters the gas-liquid separator to collect the separated products separately.

[0033] The combustion reactor temperature is stable at 800°C, and the air reactor is stable at 700°C. The ash produced by coke combustion contains alkali metals, and the ash separated and collected by the dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com