Absolute ethyl alcohol production device

An anhydrous ethanol and production device technology, which can be used in biochemical cleaning devices, enzymology/microbiology devices, liquid production bioreactors, etc., can solve the problems of low production cost and low energy consumption, and achieve low production cost, The effect of low energy consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

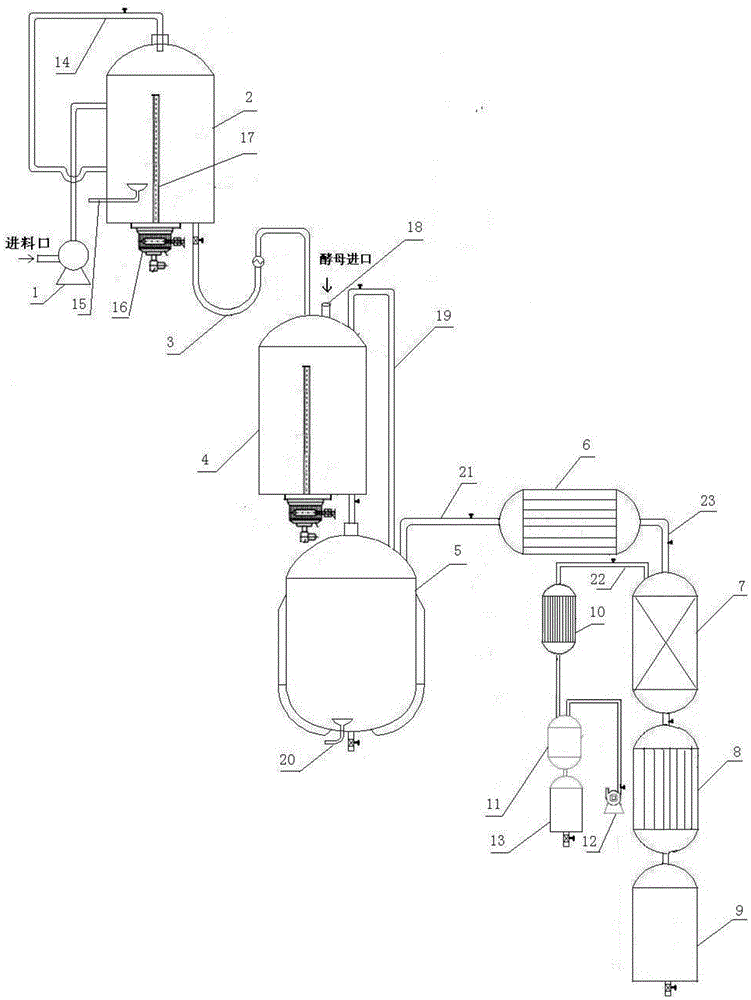

[0022] as attached figure 1 As shown, the absolute ethanol production device includes a feed pump 1, an enzymolysis tank 2, a fermenter 4, a distillation tank 5, a superheater 6 and an adsorber 7, which are connected in sequence; the bottom of the enzymolysis tank 2 A steam inlet pipe A15 is provided, and the bottom ends of the enzymolysis tank 2 and the fermentation tank are respectively provided with a stirrer 16, and above the stirrer 16, a stirring rod 17 is arranged, and the stirring rod 17 is respectively arranged at the enzymolysis tank 2 and the fermentation tank. In the lower part of the tank, the bottom of the enzymolysis tank 2 is provided with a U-shaped conduit 3 connected to the fermenter 4, and the top of the fermenter 4 is also provided with a feeding port 18, and the bottom of the fermenter 4 is connected to the top of the distillation tank 5 through a conduit. The bottom of the retort 5 is also provided with a steam inlet pipe B20, and the top of the retort 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com