Method for electrochemically depositing silver nanoparticles in titanium dioxide nanotube array

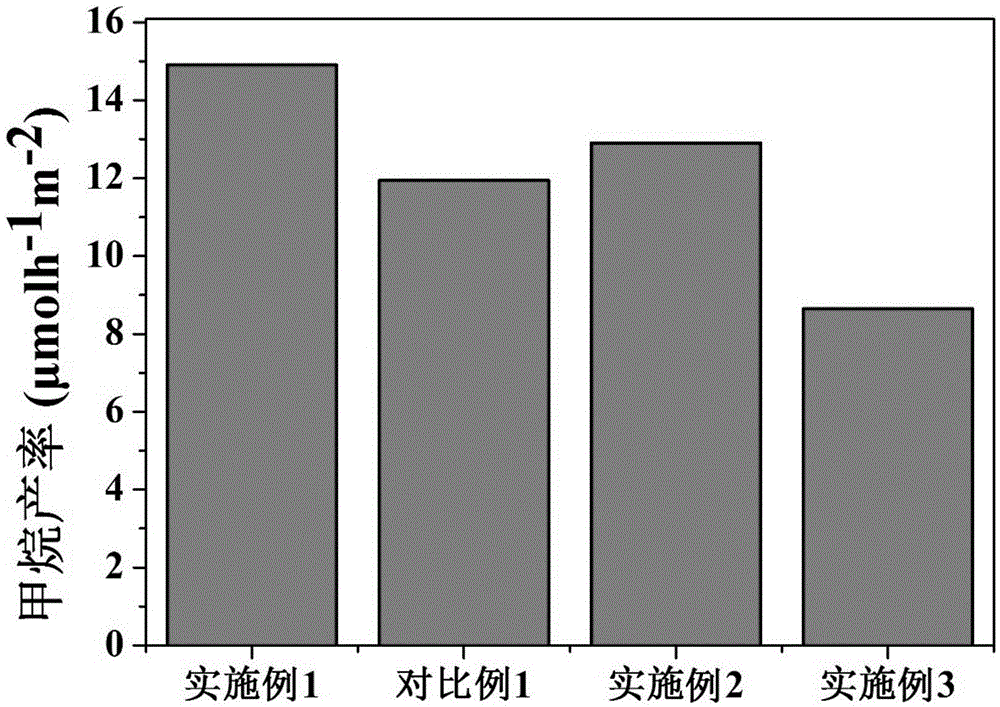

A technology of nanotube arrays and silver nanoparticles, which is applied in the field of photocatalytic material synthesis, can solve problems such as the inability to deposit Ag nanoparticles, and achieve the effect of simple operation and excellent photocatalytic reduction of CO2 activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

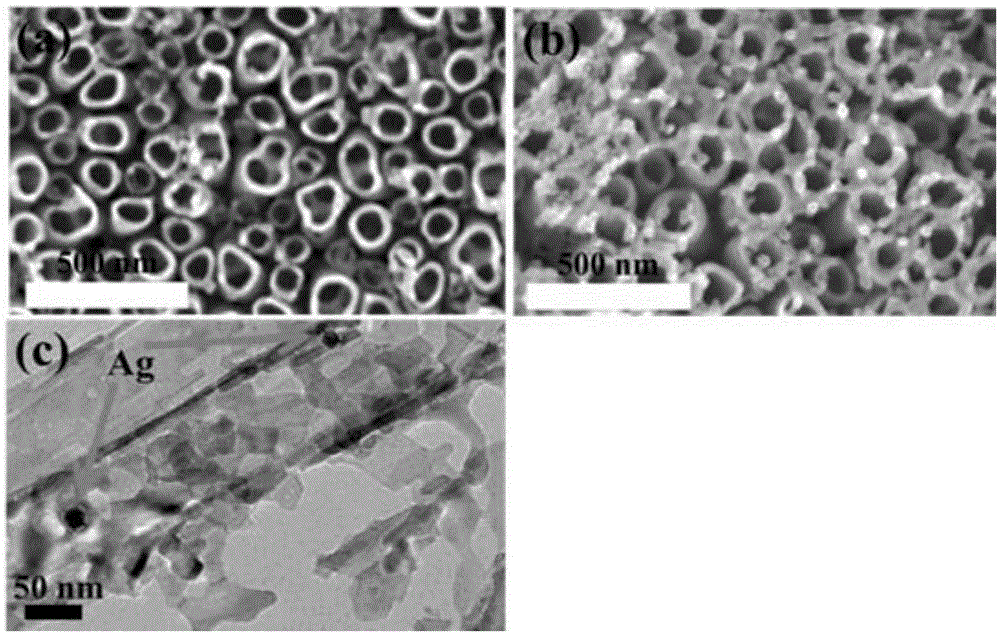

[0045] The steps of the preparation method of electrochemically depositing silver nanoparticles in the titanium dioxide nanotube array are as follows:

[0046] a) Titanium sheet surface removal treatment: Soak the titanium sheet in concentrated sulfuric acid for 6 hours, then clean it with deionized water, smooth the surface of the titanium sheet with sandpaper, and then put the titanium sheet into water: nitric acid according to the volume ratio : Soak in the polishing solution made of hydrofluoric acid = 6:3:1 for 5 minutes, ultrasonically clean with ethanol solution, and dry for use;

[0047] b) Preparation of TiO on the surface of titanium sheet 2 Nanotube array: the titanium sheet treated in step a) is used as anode and cathode. Among them, the length of the anode is 6cm, the width is 5.5cm, and the thickness is 0.25mm; the length of the cathode is 6cm, the width is 6.5cm, and the thickness is 0.25mm. The distance between the anode and cathode was 4 cm. The anode and c...

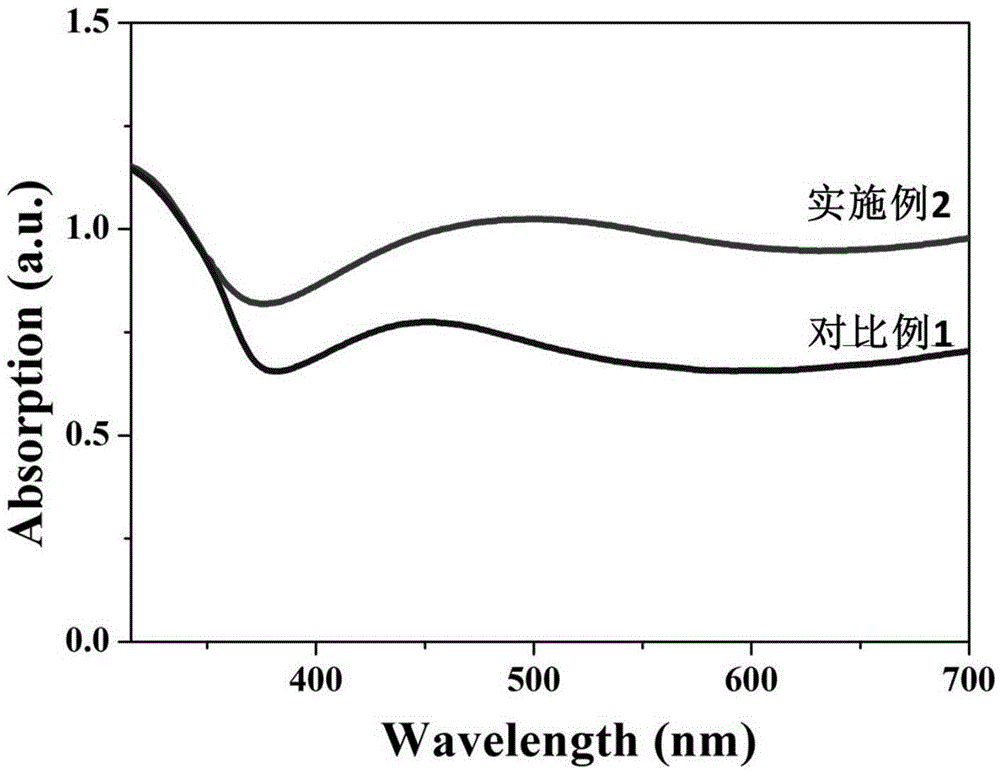

Embodiment 2

[0070] The steps of the preparation method of electrochemically depositing silver nanoparticles in the titanium dioxide nanotube array are as follows:

[0071] a) Impurity removal treatment on the surface of the titanium sheet: Soak the titanium sheet in a mixed solution of 15vt% acetone, 20vt% ethanol and 65vt% deionized water for 6 hours, then clean it with deionized water, and polish the surface of the titanium sheet with sandpaper Smooth, then put the titanium sheet into the polishing solution prepared by volume ratio of water: nitric acid: hydrofluoric acid = 6:3:1, soak for 5 minutes, ultrasonically clean with ethanol solution, dry and set aside;

[0072] b) Preparation of TiO on the surface of titanium sheet 2 Nanotube array: the titanium sheet treated in step a) is used as anode and cathode. The anode is 6cm long, 5.5cm wide, and 0.25mm thick; the cathode is 6cm long, 6.5cm wide, and 0.25mm thick. The distance between the anode and cathode was 3 cm. The anode and th...

Embodiment 3

[0078] The steps of the preparation method of electrochemically depositing nano-silver particles in the titanium dioxide nanotube array are as follows:

[0079] a) Titanium sheet surface removal treatment: Soak the titanium sheet in concentrated sulfuric acid for 6 hours, then clean it with deionized water, smooth the surface of the titanium sheet with sandpaper, and then put the titanium sheet into water: nitric acid according to the volume ratio : Soak in the polishing solution made of hydrofluoric acid = 6:3:1 for 5 minutes, ultrasonically clean with ethanol solution, and dry for use;

[0080] b) Preparation of TiO on the surface of titanium sheet 2 Nanotube array: the titanium sheet treated in step a) is used as anode and cathode. Among them, the length of the anode is 6cm, the width is 5.5cm, and the thickness is 0.25mm; the length of the cathode is 6cm, the width is 6.5cm, and the thickness is 0.25mm. The distance between the anode and cathode was 5 cm. The anode and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com