High-temperature high-dust content high-corrosion waste heat boiler of metallurgical industry

A waste heat boiler, corrosive technology, applied in the direction of furnace, waste heat treatment, steam superheating, etc., to achieve the effect of preventing ash accumulation and bridging between pipes, ensuring continuity and operability, and reducing production energy consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

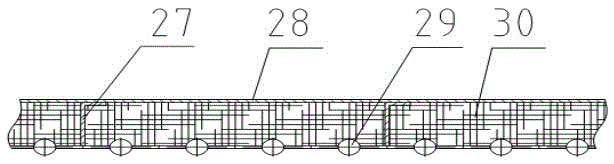

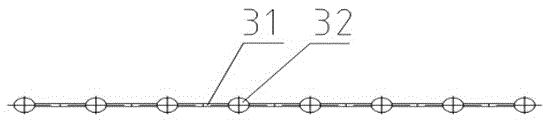

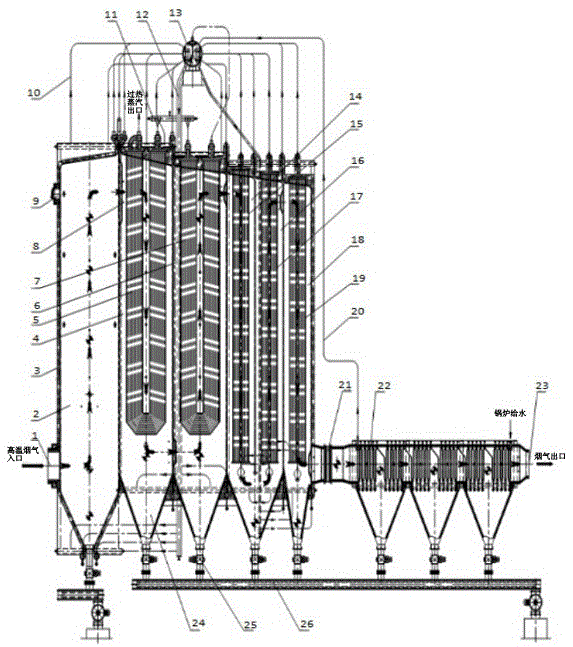

[0021] Below in conjunction with accompanying drawing, the present invention is further described; figure 1 The arrow direction shown indicates the direction of high-temperature flue gas; its structure mainly includes: high-temperature radiation deposition chamber (2), cooling chamber I (4), high-temperature screen superheater (5), cooling chamber II (6), low-temperature screen type superheater (7), boiler drum (13), cooling chamber III (14), convective evaporation tube panel I (15), cooling chamber IV (16), convective evaporation tube panel II (17), cooling chamber V ( 18), convection evaporation tube panel III (21) and economizer convection tube bundle (22). A high-temperature panel superheater (5) is installed in the cooling chamber I (4), a low-temperature panel superheater (7) is installed in the cooling chamber II (6), and a convective evaporation is installed in the cooling chamber III (14). Tube panel I (15), convective evaporation tube panel II (17) is provided in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com