System and method for heating boiler feed water through steam turbine bypass steam

A technology for bypassing steam turbines and heating boilers, which is applied in the field of electric power, can solve problems such as affecting the finishing operation, prolonging the start-up time, reducing the efficiency of steam turbines, etc., and achieves the favorable effects of accelerating the quality of soda water, accelerating the start-up speed and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

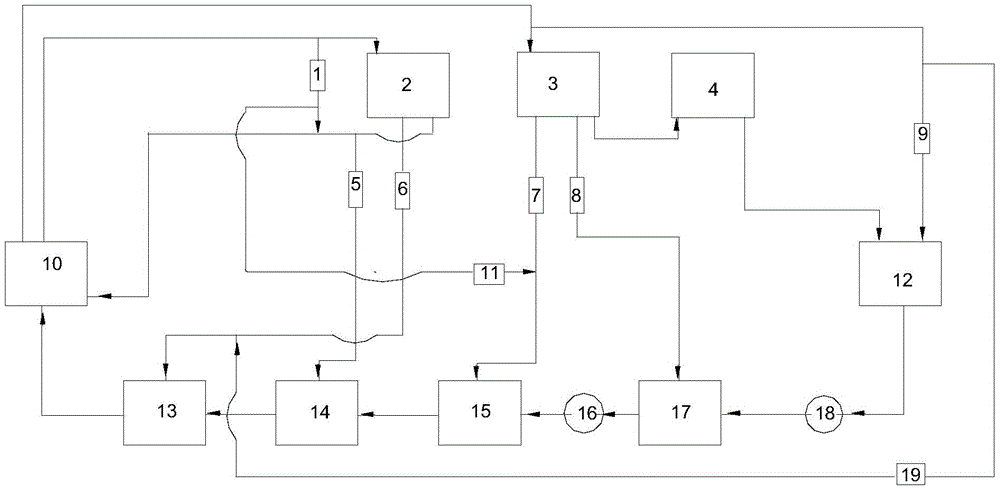

[0037] Such as figure 1 As shown, the present invention utilizes steam turbine bypass steam heating boiler feed water system, including high pressure bypass regulating valve 1, high pressure cylinder 2, medium pressure cylinder 3, low pressure cylinder 4, second valve group 5, first valve group 6 , the third valve group 7, the fourth valve group 8, the low pressure bypass regulating valve 9, the boiler 10, the fifth valve group 11, the condenser 12, the first high pressure heater 13, the second high pressure heater 14, the third High pressure heater 15 , feed water pump 16 , deaerator 17 , condensate water pump 18 and sixth valve group 19 .

[0038] Among them, the first outlet of the boiler 10 is divided into two strands, the first strand is connected to the inlet of the high-pressure cylinder 2, and the second strand is connected to the inlet of the high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com