Micro emission pulverized coal combustion system

A technology of pulverized coal combustion and pulverized coal burner, which is applied in the direction of combustion type, combustion equipment, combustion method, etc., can solve problems such as NOx pollution of the environment, and achieve the effects of reducing NOx production, realizing NOx emission, and reducing NOx production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

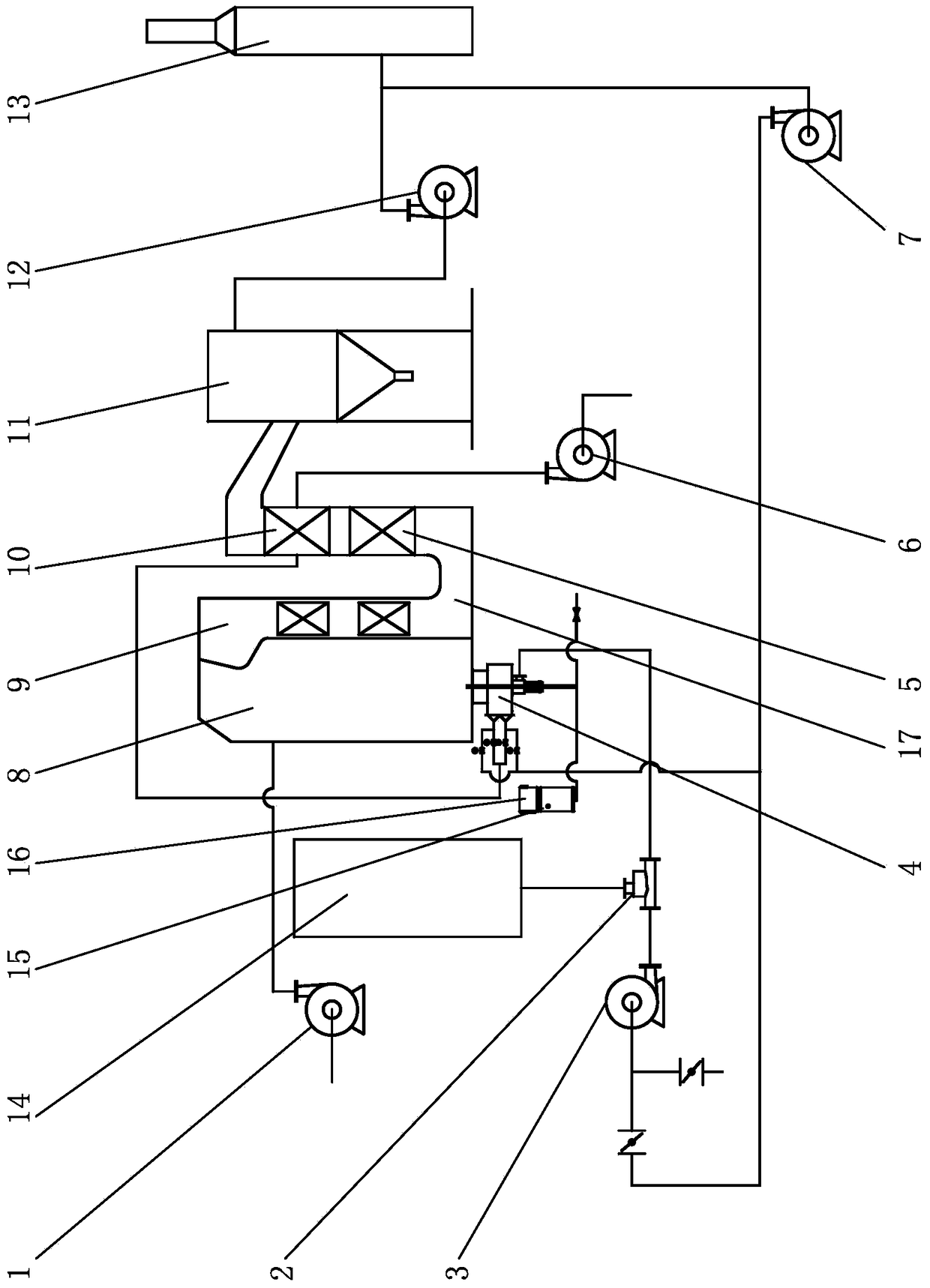

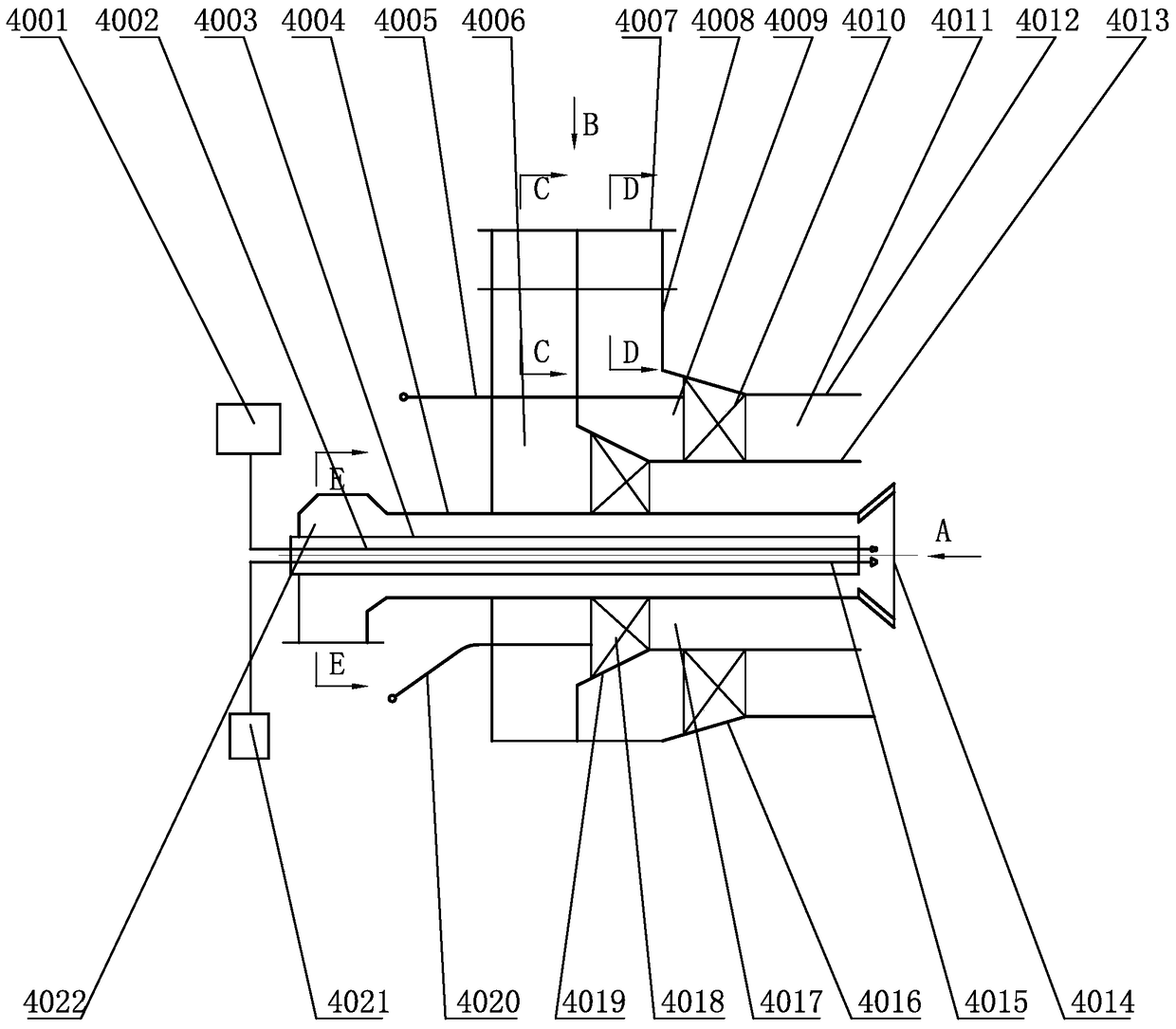

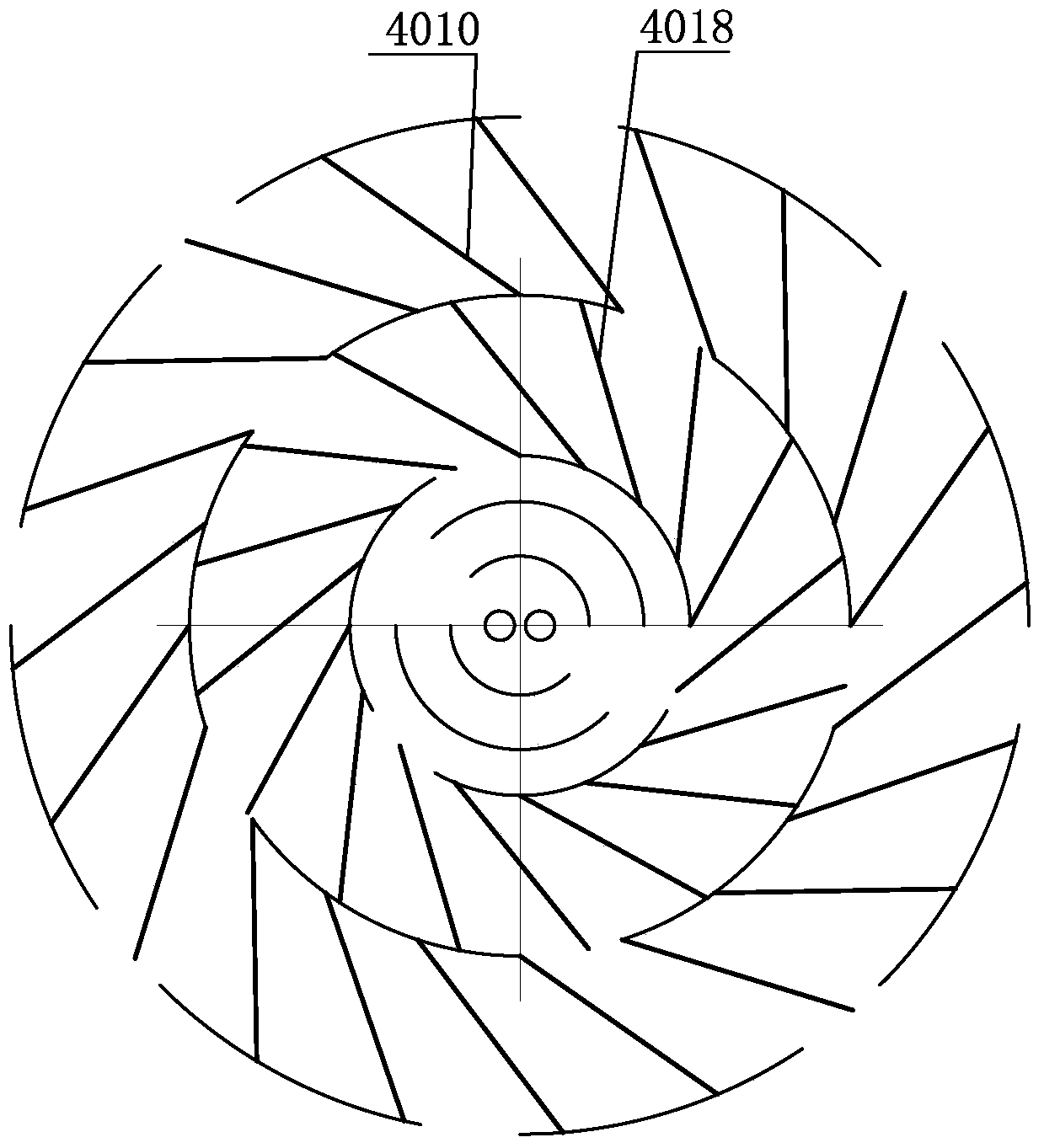

[0032] refer to figure 1, the micro-emission pulverized coal combustion system of the present invention includes a three-time burnout fan 1, an air-powder mixer 2, a primary powder delivery fan 3, a pulverized coal burner 4, an economizer 5, a secondary combustion-supporting fan 6, and a quaternary smoke Gas return fan 7, boiler furnace 8, boiler convection flue 9, air preheater 10, dust collector 11, induced draft fan 12, pulverized coal tower 14 and desulfurization tower 13. Described pulverized coal burner 4 is arranged on the bottom of described boiler hearth 8; Two output ends of described air-powder mixer 2 are respectively connected to described primary powder fan 3 and air-powder mixer 2, and the air The output end of the powder mixer 2 is connected to the primary air duct of the pulverized coal burner 4; the input end of the secondary combustion air blower 6 is connected to the cold side channel of the air preheater, and the output end is connected to the coal The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com