Energy-saving method for catalytic oxidation treatment of large flow vocs gas

A catalytic oxidation and large flow technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of hidden dangers of explosion, high energy consumption, high electric heating power, etc., and achieve the goals of improving emission indicators, low energy consumption, and saving energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

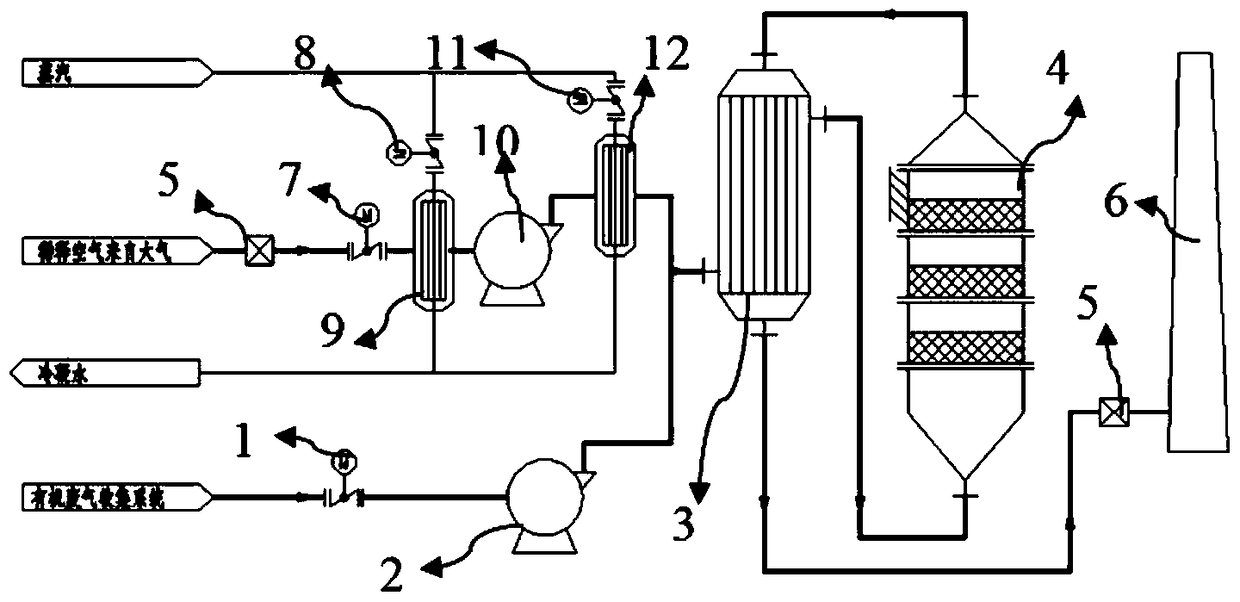

[0021] The invention provides an energy-saving method for catalytic oxidation treatment of large-flow VOCs gas, comprising the following steps:

[0022] aA secondary steam heating system is used to heat the air. The air is first preheated by the air preheater, and the preheated air is then reheated by the air heat exchanger. When the air passes through the air preheater and the air heat exchanger, it exchanges heat with the steam. The steam flow is controlled by the steam regulating valve. After the steam condenses, it forms condensed water and returns to the steam generator for recycling. The large flow of VOCs gas to be treated is mixed with the heated hot air to obtain a mixed gas, and the concentration of the VOCs gas in the mixed gas is controlled below the lower limit of the explosion limit.

[0023] b. Transporting the mixed gas obtained in step a to a catalytic reactor for catalytic oxidation reaction. The structure of the supporting bed in the catalytic reactor adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com