Novel hollow cathode

A hollow cathode, a new type of technology, applied in discharge tubes, electrical components, ion beam tubes, etc., can solve problems such as overheating and high power consumption, and achieve the effects of reducing anode discharge voltage, reducing power consumption, and improving discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

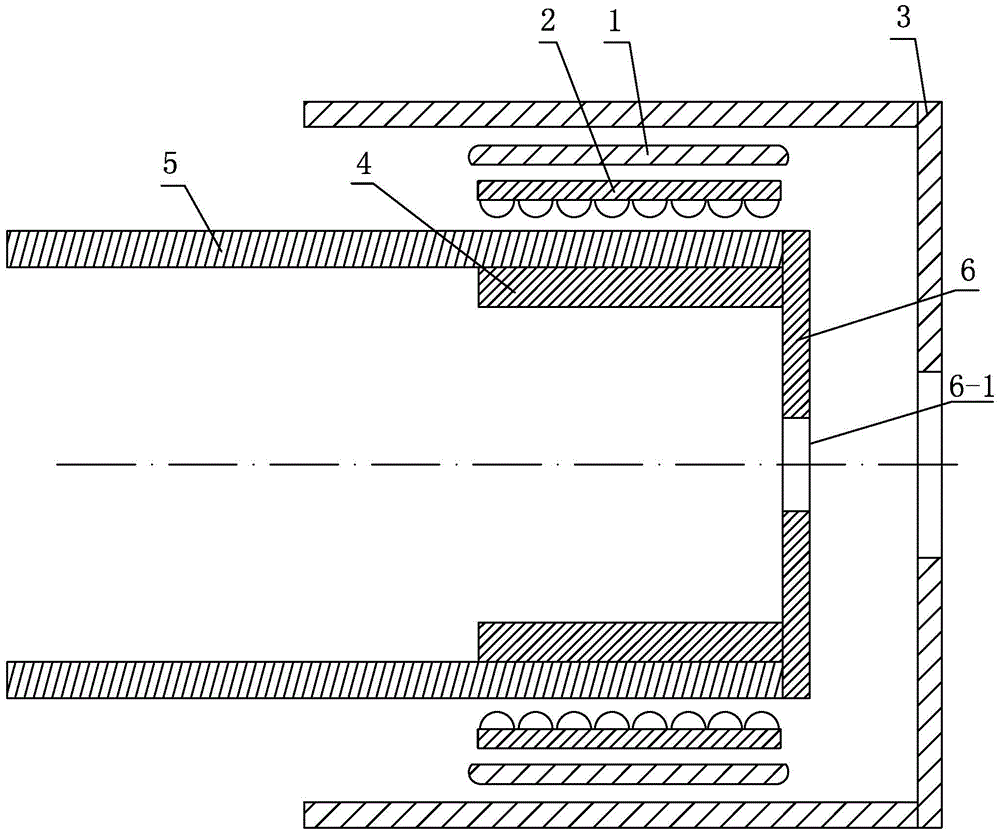

[0007] Specific implementation mode one: combine figure 1 Explain that a new type of hollow cathode in this embodiment includes a heat shield 1, a heater 2, a holding electrode 3, an emitter 4, a cathode tube 5 and a cathode top plate 6; a heat shield 1 is arranged inside the holding electrode 3 from outside to inside , heater 2, cathode tube 5 and emitter 4; emitter 4 is installed on the inner wall of cathode tube 5, cathode top plate 6 is installed on the bottom of cathode tube 5, and the middle part of cathode top plate 6 is provided with through hole 6-1, cathode The material of the top plate 6 - 1 is the same as that of the emitter 4 .

[0008] The heat shield 1, the contact electrode 3, the emitter 4 and the cathode tube 5 are all cylindrical structures. The through hole 6-1 is a circular through hole.

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Note that the material of the emitter in this embodiment is single crystal lanthanum hexaboride. The cathode top plate material is the same as the emitter material. The single crystal lanthanum hexaboride has a good structure, high purity (less impurities), strong anti-pollution and anti-poisoning ability, and strong electron emission ability, which can reach 30-40A / cm 2 , which is about three times the emission capability of polycrystals. In addition, the performance of single crystal lanthanum hexaboride is more stable, and the emission capability is easier to be activated. The power consumption of the cathode is reduced when the cathode is working at a low current, and the discharge performance of the hollow cathode is improved.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Note that the diameter of the through hole 6 - 1 in this embodiment is 0.25 mm, and the depth of the through hole 6 - 1 is 1.0 mm. When the cathode top plate of the hollow cathode adopts the same parameters as the emitter material and the above parameters, when the cathode discharge current is 0.4A and the gas supply flow rate is 2sccm, the anode discharge voltage drops by 5V compared with the cathode top plate of tungsten material. or so, the cathode power consumption is reduced by 2W.

[0011] When the cathode discharge current is 0.4A and the air supply flow rate is 1sccm, the anode discharge voltage is reduced by about 2.5V and the cathode power consumption is reduced by 1W compared with the cathode top plate made of tungsten material.

[0012] When the cathode discharge current is 0.8A and the air supply flow rate is 1sccm, the anode discharge voltage is reduced by about 1.4V and the cathode power consumptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com