Ion beam irradiation apparatus, and ion beam current homogenization method

A technology of irradiating device and beam current, which is applied to circuits, discharge tubes, electrical components, etc., to achieve high precision, avoid too large or too small, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

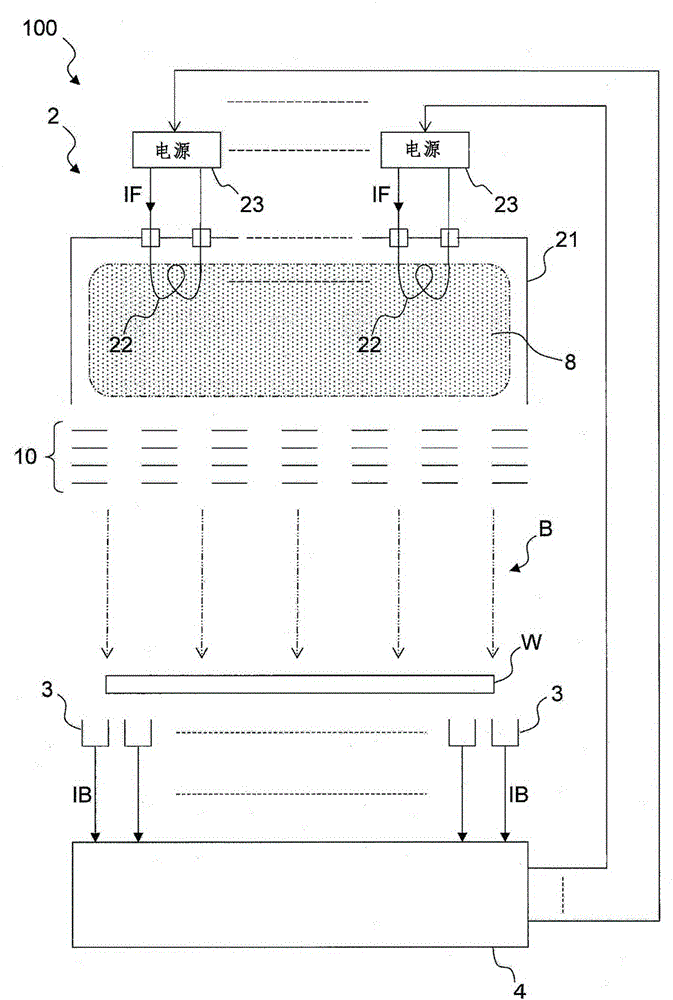

[0041] The ion beam irradiation apparatus 100 described above is used, for example, in a non-mass separation type ion implantation apparatus, such as figure 1 As shown, the large-area ion beam B extracted from the ion source 2 via the extraction electrode mechanism 10 directly irradiates the object W to be irradiated without passing through the mass separator to perform ion implantation. When ion implantation is performed, the object W to be irradiated can be mechanically scanned, for example, in the direction inwards and outwards on the paper, within the irradiation area of the ion beam B as needed. The object to be irradiated W is, for example, a glass substrate, a semiconductor substrate, or the like.

[0042]The ion source 2 is also called a barrel ion source (or a multi-pole magnetic field type ion source), which includes: a plasma generating container 21 containing ion source gas; multiple (for example, 10) filaments 22 arranged on The plasma generating container 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com