Package structure for composite sensor module and manufacturing method of package structure

A composite sensor and packaging structure technology, applied in the field of sensors, can solve the problems of discrete device mounting and processing difficulties, high-density integration, and large module volume, and achieve the effects of shortening the development cycle, improving integration, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

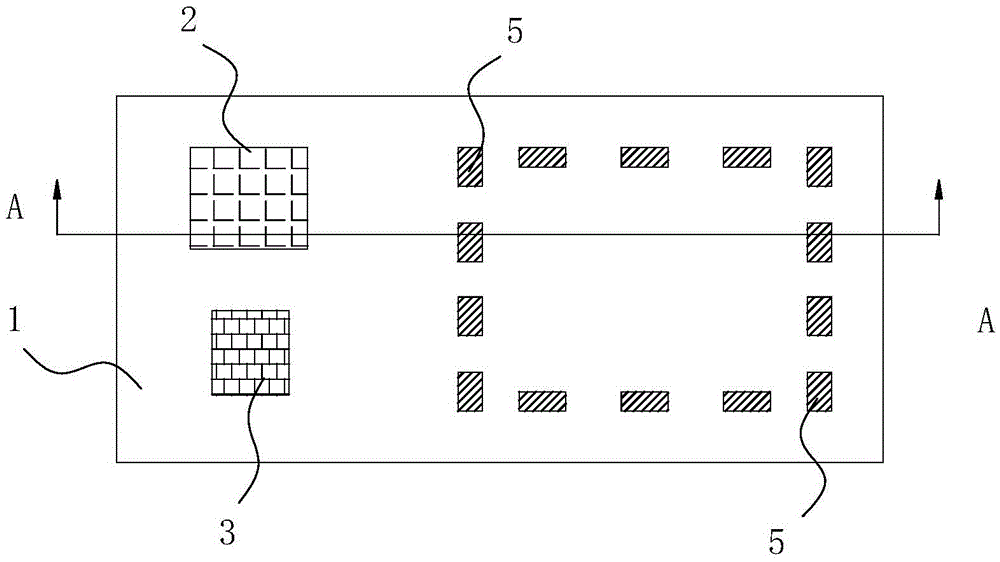

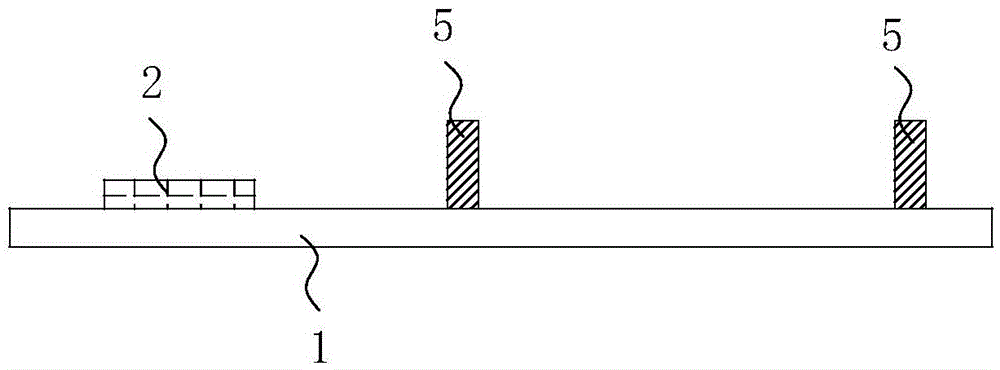

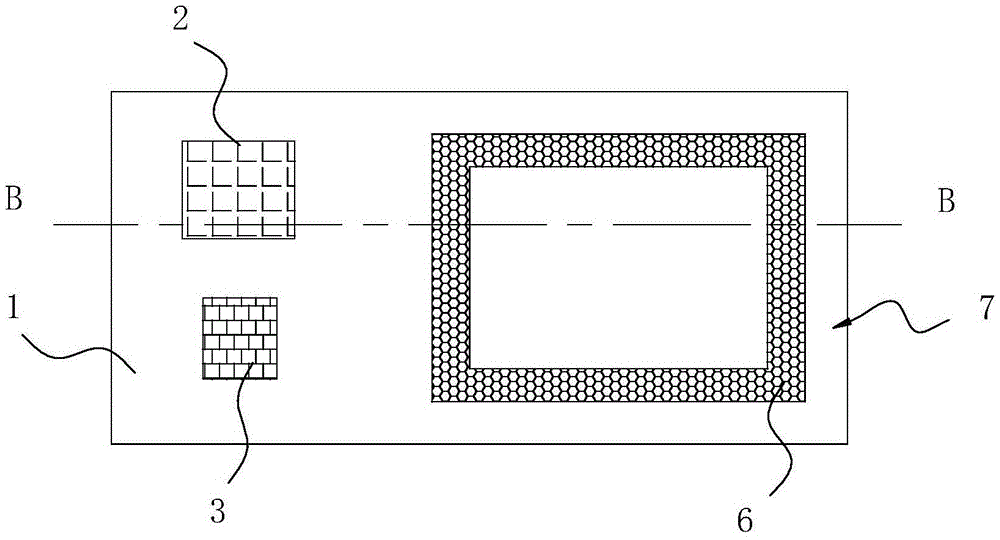

[0046]In this embodiment, the packaging structure of a composite sensor module according to the present invention includes a substrate 1, on which there is a sensor chip mounting area surrounded by a number of discrete devices 5, and a sensor chip mounting area located on the sensor chip mounting area. In other chip mounting areas outside the area, a composite function sensor chip is installed in the sensor chip mounting area, and a plugging material 6 is arranged outside the discrete device 5, and the discrete device 5 and the plugging material 6 are jointly formed The dam structure 7 of the sensor chip installation area. The other chip mounting area is provided with a first protective material 8, the setting height of the first protective material 8 is the same as the height of the dam structure 7, and the sensor chip mounting area is provided with a protective composite function sensor chip and The second protective material 9 of the metal binding wire 13, the second protec...

Embodiment 2

[0066] Such as Figure 9 As shown, the technical solution of this embodiment is basically the same as that of Embodiment 1, the main difference is that the method of dispensing the silica gel used as the second protective material 9 in the above-mentioned manufacturing method is changed to prepare a layer of protective coating 11 to protect the TPMS sensor chip 4 and the metal bonding wire 13, the protective coating 11 is used without dripping silica gel, so that the height of the dam structure 7 can be reduced, and the volume and weight of the packaging structure can be further reduced.

[0067]Specifically, the protective coating 11 is prepared after the epoxy resin as the first protective material 8 is cured, and the material of the protective coating 11 is waterproof, moisture-proof, corrosion-resistant, stable, and high-temperature-resistant to protect the TPMS sensor chip 4 and the metal bonding wire 13, and ensure that the packaged TPMS sensor package module in the subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com