Process for purifying semiconducting single-walled carbon nanotubes

A single-wall carbon nanotube, semiconductor technology, applied in carbon nanotubes, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve the problems of high cost, lack of scalability, etc., to achieve The effect of increasing yield, increasing purity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: polyfluorene derivative

[0046] This example provides details of preferred conjugated polymers.

[0047] Prepared by the Suzuki reaction (Suzuki reaction) adapted from prior art methods (eg Ding2002) 8 to C 18 Polyfluorene with two alkyl groups of length. The obtained polymers with basic characterization data are listed in Scheme 1 and Table 1, where T d 1% and T g is measured by thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) curves.

[0048]

[0049] Scheme 1: Structure of polyfluorene

[0050] Table 1: Characterization data of polyfluorene

[0051] polymer

Embodiment 2

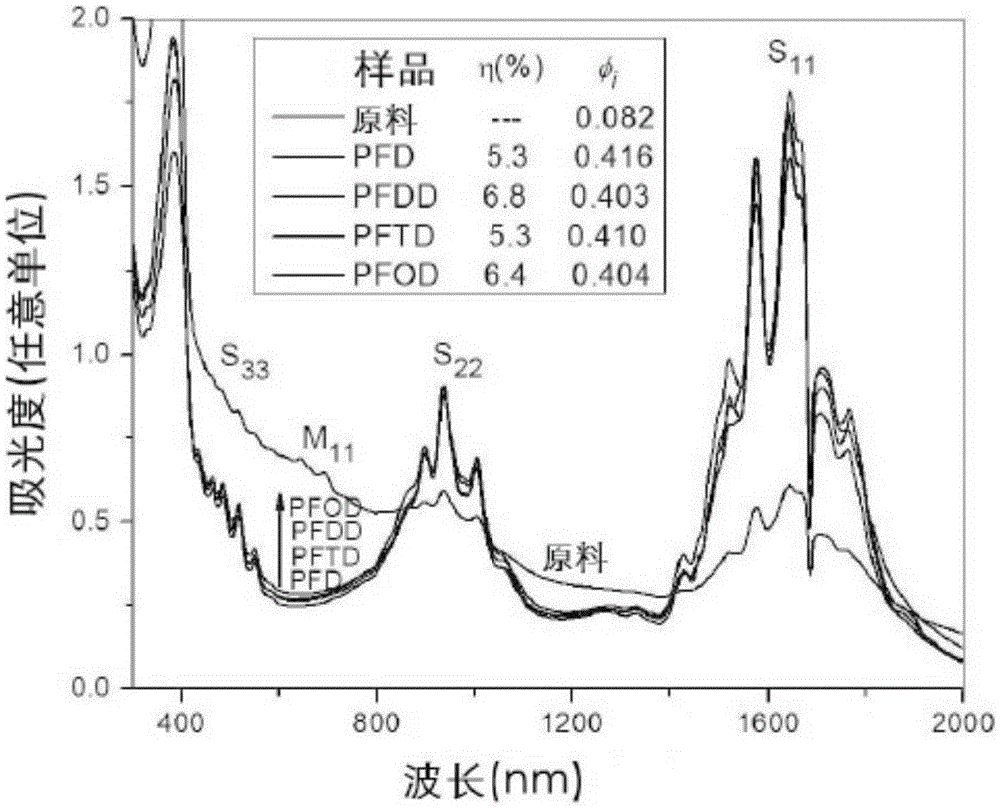

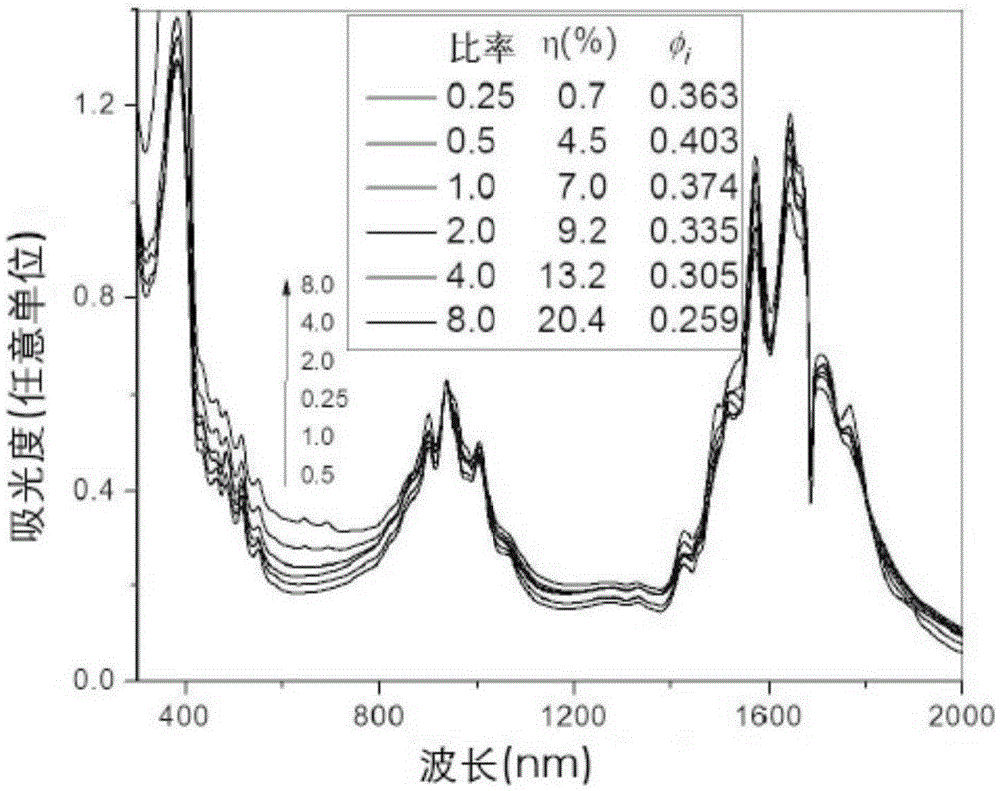

[0052] Example 2: Enrichment of original SWCNTs with polyfluorene derivatives

[0053] This example provides details of extraction of mixtures of sc-SWCNTs and m-SWCNTs using conjugated polymers to generate enriched sc-SWCNT dispersions.

[0054] A typical enrichment was performed by dispersing 25 mg of laser ablation-generated SWCNTs together with 20 mg of polyfluorene into 50 mL of toluene. The mixture was homogenized at 30° C. for 30 minutes using a horn sonicator with a 10 mm tip (Branson Sonicator 250, maximum power: 200 W) operated at 40% duty cycle and 50% output. The dispersion was then centrifuged at a relative centrifugal force (RCF) of 7600 g (8,000 rpm on a SS-34 rotor) for 30 minutes. Pass the supernatant through Teflon with 0.2 μm pore size TM Membrane filtration to collect the extracted SWCNTs. The collected SWCNTs were rinsed twice with 5 mL of toluene to remove free polyfluorene, and then redispersed in 5 mL of toluene for 5 to 10 min using a bath sonicator...

Embodiment 3

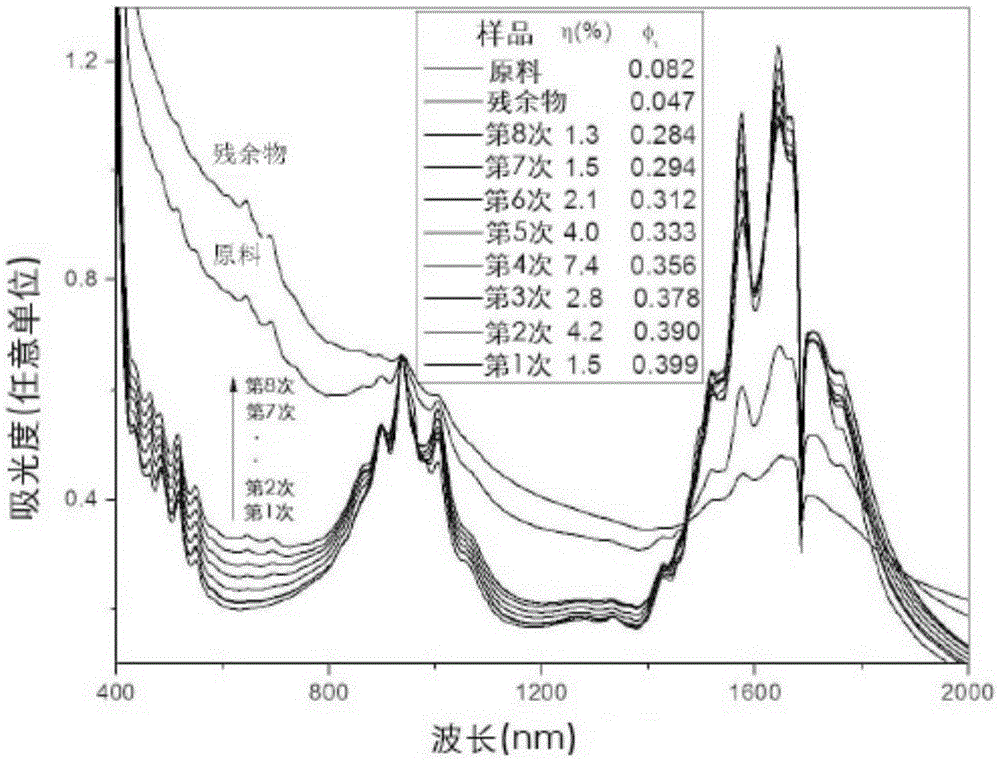

[0072] Example 3: Using an inorganic adsorption medium to improve the purity of large-diameter sc-SWCNTs enriched with polyfluorene derivatives

[0073] This example provides details of exposing the enriched sc-SWCNT dispersion from Example 1 to an inorganic adsorption medium in a non-polar solvent to further increase the purity of the sc-SWCNTs. The inorganic adsorption medium used in this example was unmodified silica gel and composed of various functional groups, namely 3-cyanopropyltriethoxysilane (CPTES), 3-aminopropyltriethoxysilane (APTES ) and 0.1% poly-L-lysine modified silica gel. Silica gel (Macherey-Nagel company, Pore size) was purchased from Rose Scientific Co., Ltd. 3-cyanopropyltriethoxysilane (CPTES), 3-aminopropyltriethoxysilane (APTES) and 0.1% poly-L-lysine aqueous solution were obtained from Sigma-Aldrich (Sigma-Aldrich) obtained and used as is.

[0074] Preparation of silica gel and surface-modified silica gel

[0075] Macherey-Nagel silica gel wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com