Mixed pellet feed directly prepared from optimally-proportioned dry matter of whole-plant corn in squeezing and extruding mode

A whole-plant corn and pellet feed technology, which is applied in animal feed, animal feed, application, etc., can solve the problems of mixed effect of roughage raw materials, lack of concentrated feed resources, and low utilization of roughage, so as to improve feed conversion rate and feed convenience Low, good feed palatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

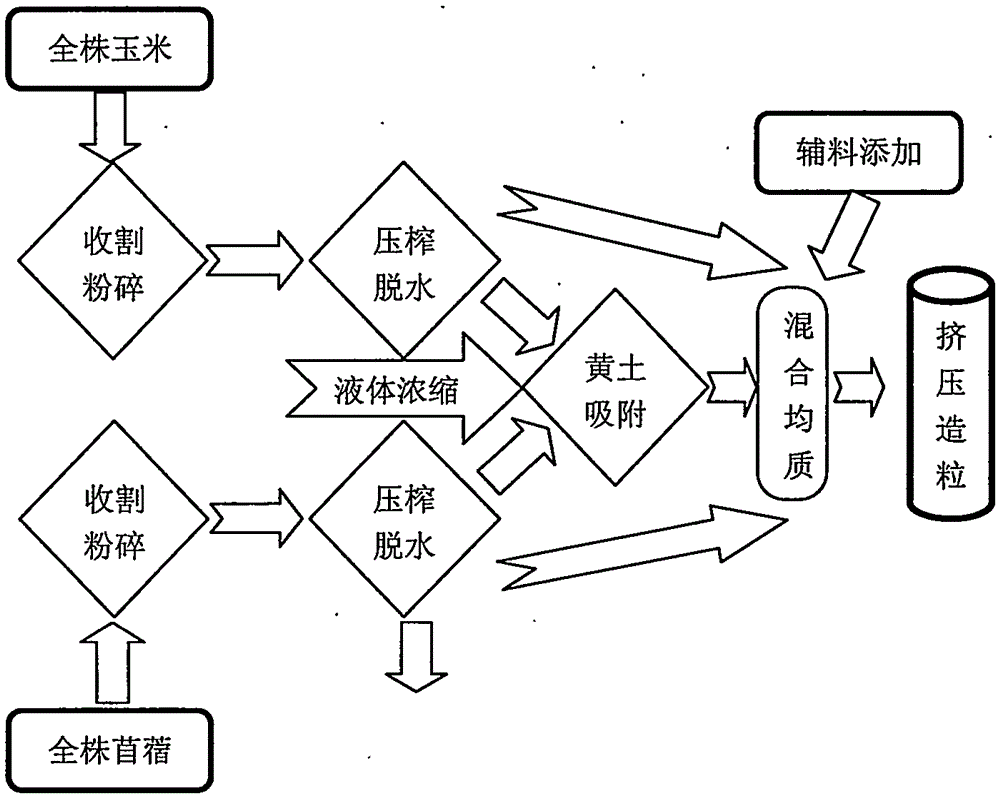

[0045] Embodiment 1: as attached figure 1 As shown, the whole plant corn and the whole plant alfalfa are mechanically harvested and pulverized at the same time, and then pressed and dehydrated to reduce the weight by 30-40%. The dry materials of whole plant corn and whole plant alfalfa after being squeezed are mixed and homogenized at a ratio of 1:1, and then extruded and granulated. The color of the obtained pellet feed is yellow-green, lumpy, free of mold, and has a moisture content of 9.49%. Crude protein 11%, crude fat 2.51%, crude fiber 58%, crude ash 25.23%, nitrite 13mg / kg, density 435kg / m 3 .

[0046] In the foregoing, the dried corn or stalks are pulverized and then added as auxiliary materials, mixed and homogeneously granulated. Moisture was reduced to 8.3% after granulation.

[0047] In the foregoing, the whole plant corn is harvested and chopped into 1-5 cm lengths simultaneously.

[0048] In the foregoing, no stubble is left when the whole plant corn is harve...

Embodiment 2

[0053] Embodiment 2: When the whole plant corn is harvested, the stubble is 35-53 cm. The stubble is re-harvested and used separately. The crude protein content of stubble harvested and crushed corn silage material was significantly increased, and at the same time, the indigestible fiber was significantly decreased.

[0054] In the present invention, adding crushed yellow storage or dried old corn stalks is beneficial to absorbing the moisture of the corn, so as to quickly reduce the moisture and increase the crude protein content.

[0055] In the present invention, the whole plant is harvested and crushed, the overall corn plant material is not wasted, the land is convenient for plowing, fast and efficient, the cost is reduced, the loss of nutrients is avoided, the intermediate links are reduced, and the process and production storage are greatly saved, which can effectively improve Its feed intake, organic matter digestibility, and feeding effect on dairy cows are slightly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com