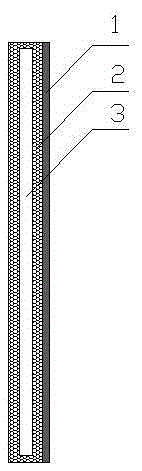

Vacuum insulation composite decoration insulation board and preparation mold thereof

A vacuum insulation board and vacuum insulation technology, which is applied in the direction of heat preservation, insulation improvement, building components, etc., can solve the problems of cumbersome construction of exterior walls, large thickness of heat preservation materials, and influence on heat preservation effect, etc., so as to optimize heat preservation effect and reduce Effect of thickness, optimized size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] Described preparation method comprises the steps:

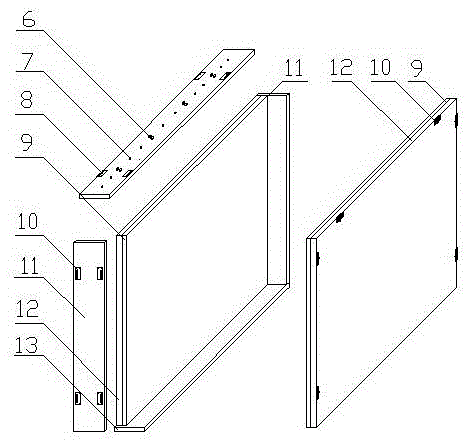

[0093] 1) The inner surface of the large side plate 9 and the small side plate 11 is coated with a release agent, and the decorative plate is closely attached to the inner surface of a large side;

[0094] 2) The small side plates 11 are arranged around the two relatively large side plates 9 to close three of the four sides of the large side plates, thereby forming a mold with only one side opening; as image 3 headspace shown;

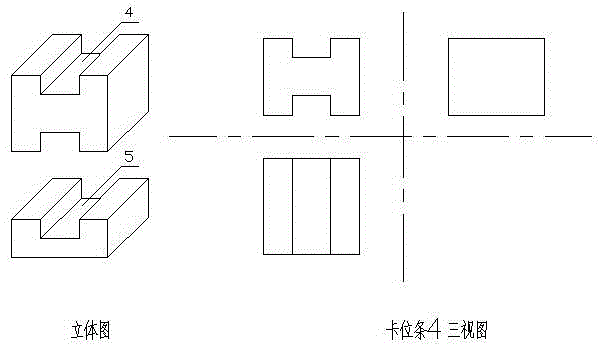

[0095] 3) Place the edge of the vacuum insulation panel in the groove of the foam clamping strip, and clamp the edge of the vacuum insulation panel through the foam clamping strip;

[0096] 4) Pass the vacuum insulation panel with the foam clip through the opening of the mold (such as image 3 the upper space shown) into the mold, and then cover the opening of the mold with a small side plate;

[0097] 5) Turn on the mold heating plate for heating, control the temperature inside the mold at...

Embodiment 1

[0125] A vacuum insulation composite decorative thermal insulation board for ultra-low energy buildings, comprising a vacuum insulation board, a two-component polyurethane rigid foam, and a decorative board, prepared by the following method:

[0126] (1) Coat the inner surface of the mold with polyurethane oil-based release agent, and stick a decorative plate with a thickness of 10mm, a base material of silicon-calcium board, and a decorative surface of imitation marble color stone paint on the large side of the mold 9 (such as image 3 ), and then assemble the various components, and fill a polyurethane rigid foam cuboid with a size of 180×1240×50 inside to form a foaming space with an internal space of 1680×1240×50mm.

[0127] (2) Install the polyurethane foam clamp strip on the vacuum insulation board with the size of 600×400×20mm (such as Figure 5 ), and placed in the mold one by one, covered with the top plate of the mold and fixed, the thermal conductivity of the vacuum...

Embodiment 2

[0133] (1) Coat the inner surface of the mold with polyurethane oil-based release agent, and stick a 10mm thick decorative plate with glass magnesium board as the base material and fluorocarbon paint on the large side of the mold (such as image 3 ), and then assemble the various components, and fill a polyurethane rigid foam cuboid with a size of 180×1240×50 inside to form a foaming space with an internal space of 1680×1240×50mm.

[0134] (2) Install the XPS foam clamping strips on the vacuum insulation panels with a size of 600×400×15mm, and place them in the mold one by one, cover and fix the top plate of the mold, and the thermal conductivity of the vacuum insulation panels used is 0.0020W / (m·K).

[0135] (3) Turn on the heating device of the mold to heat the mold, and stop heating when the temperature reaches 50°C.

[0136] (4) Use a foaming machine to inject 3500g of polyurethane rigid foam composite material into the mold through the injection hole. The thermal conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com