Preparation method of highly pure alumina

A high-purity alumina and alumina technology, applied in the purification of aluminate/alumina/aluminum hydroxide, etc., can solve the problems of complex process flow, serious environmental pollution and high production hazard, and achieve simple process flow and high production efficiency. Wide range of conditions, high purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

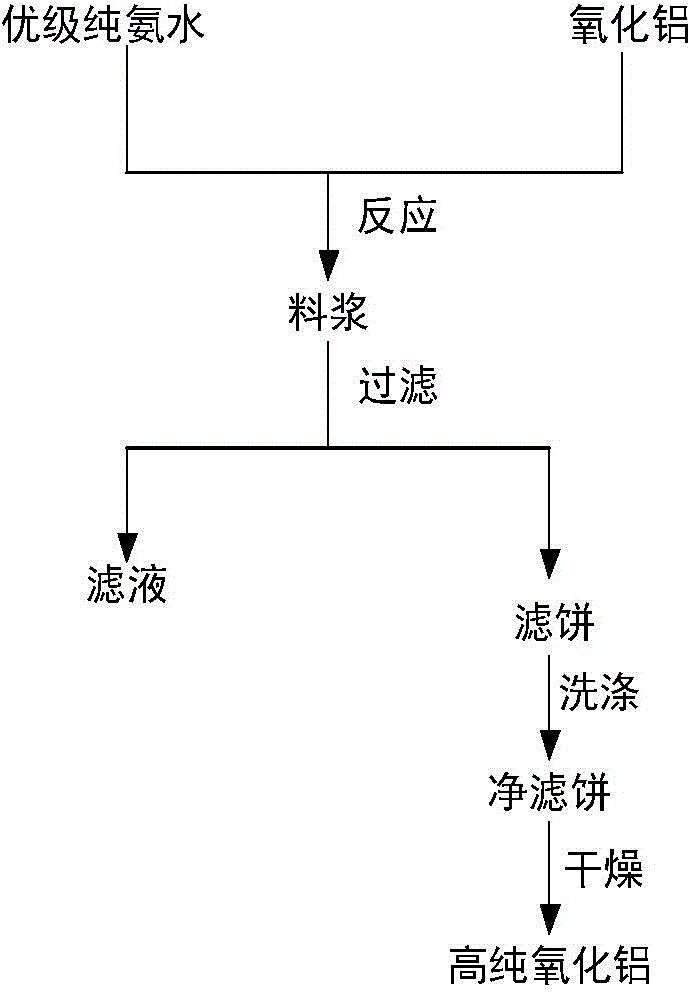

Image

Examples

Embodiment 1

[0027] The raw materials of this embodiment are aluminum oxide with a purity of 99.991% and superior pure ammonia water with a concentration of 8%. Mix the above aluminum oxide and ammonia water according to the ratio of L / S (mL / g) to 18, and mix them evenly Put the slurry into a clean reaction kettle, slowly raise the temperature to 250°C, and keep it warm at 250°C for 7 hours. After the reaction, the slurry is separated from liquid to solid, and the obtained filter cake is washed 5 times with 80°C high-purity water according to the water-solid ratio of 15. Drying at ℃, the purity of the obtained product is 99.9993%.

Embodiment 2

[0029] The raw materials of this embodiment are alumina with a purity of 99.995% and superior pure ammonia water with a concentration of 3%. Mix the above alumina and ammonia water according to the ratio of L / S (mL / g) to 30, and mix them evenly Put the slurry into a clean reaction kettle, raise the temperature slowly to 200°C, and keep it warm at 200°C for 9 hours. After the reaction, the slurry is separated from liquid to solid. Drying at ℃, the purity of the obtained product is 99.9992%.

Embodiment 3

[0031] The raw materials of this embodiment are aluminum oxide with a purity of 99.95% and superior pure ammonia water with a concentration of 9%. Mix the above aluminum oxide and ammonia water according to the ratio of L / S (mL / g) to 40, and mix them evenly Put the slurry into a clean reaction kettle, slowly raise the temperature to 230°C, and keep it warm at 230°C for 20 hours. After the reaction, the slurry is separated from liquid to solid, and the obtained filter cake is washed 5 times with 95°C high-purity water according to the water-solid ratio of 15. Drying at ℃, the purity of the obtained product is 99.9991%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com