Novel method utilizing sea beach sludge to make bricks

A new technology of beach silt, which is applied in the field of making bricks using silt from coastal beaches and estuary beaches as raw materials, can solve the problems of unfavorable sustainable development and large consumption, and achieve the effect of saving cultivated land resources and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

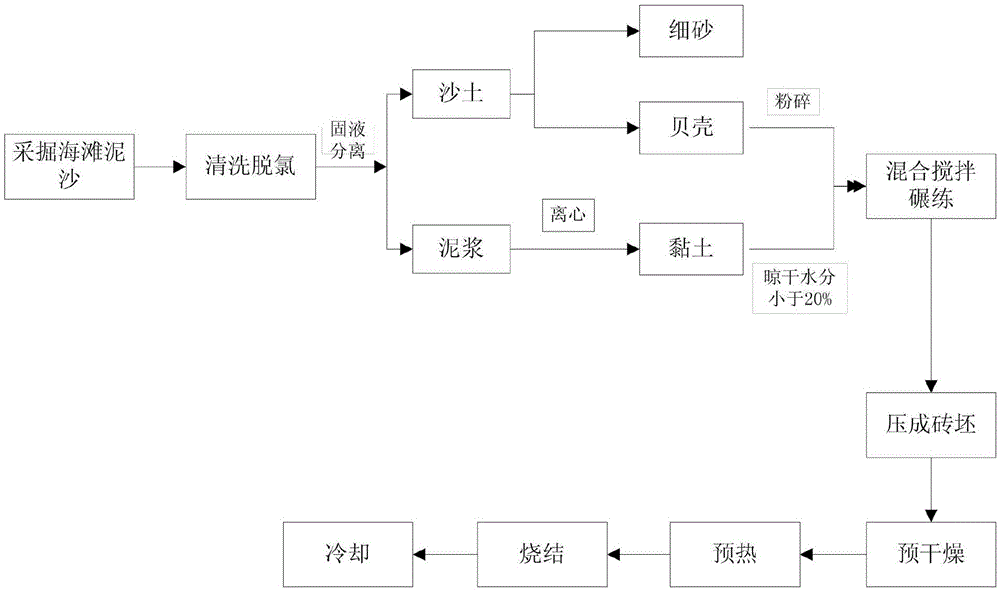

[0028] A method for making bricks from beach silt, comprising the following steps:

[0029] 1) Excavation of sediment: Simultaneously excavate the sea silt and sea sand of the coastal tidal flats and estuary beaches;

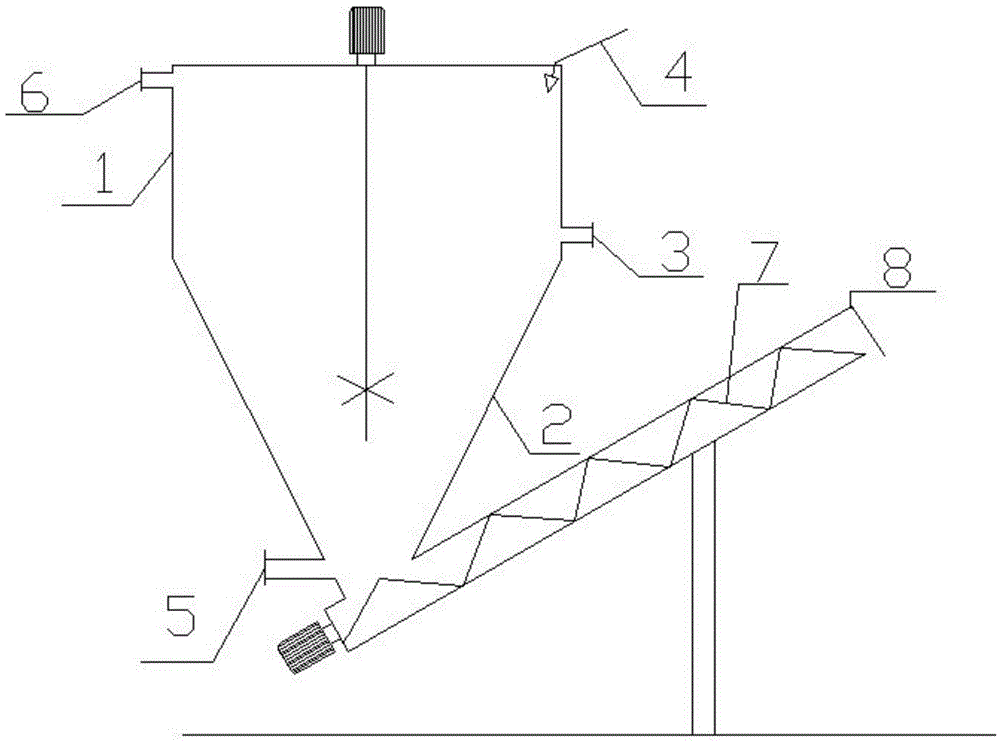

[0030] 2) Cleaning: use a large amount of clean water or reclaimed water, and use a whirlpool dechlorination device to clean the excavated sand and soil silt. After cleaning, separate the sand and silt slurry;

[0031] 3) Centrifuging the sludge slurry: drying the centrifuged sludge until the moisture is less than 20%, and drying the moisture; the centrifuged water is reused in the cleaning stage, and the chloride ion concentration in the water reaches 0.06% and is directly discharged into the sea;

[0032] 4) sieving: the shells in the sand obtained in step 2) are sorted through a 4-purpose sieve with sieve holes;

[0033] 5) Pulverization: pulverize the shells into powder, the diameter of the powder is not more than 1mm;

[0034] 6) Stirring to make billets:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com