A kind of polylactic acid composition and preparation method thereof

A composition and polylactic acid technology, applied in the field of polylactic acid composition and its preparation, can solve the problems of poor blending compatibility of polylactic acid and other polyesters, achieve low metal element content, maintain transparency and degradation performance, and improve The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

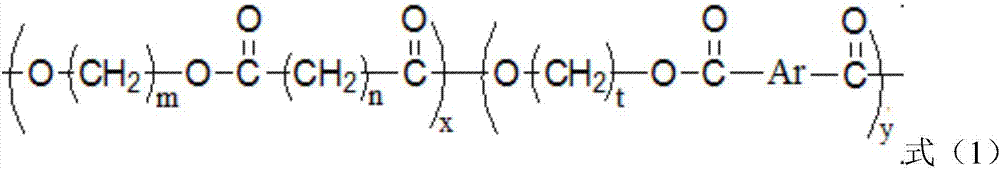

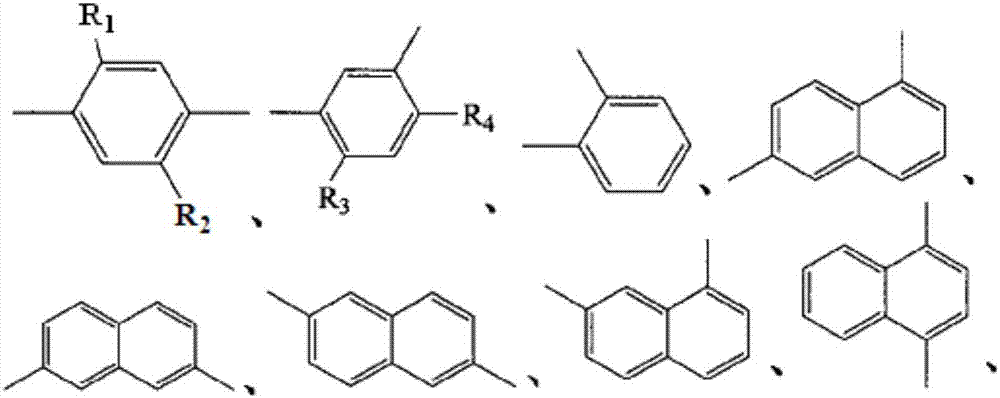

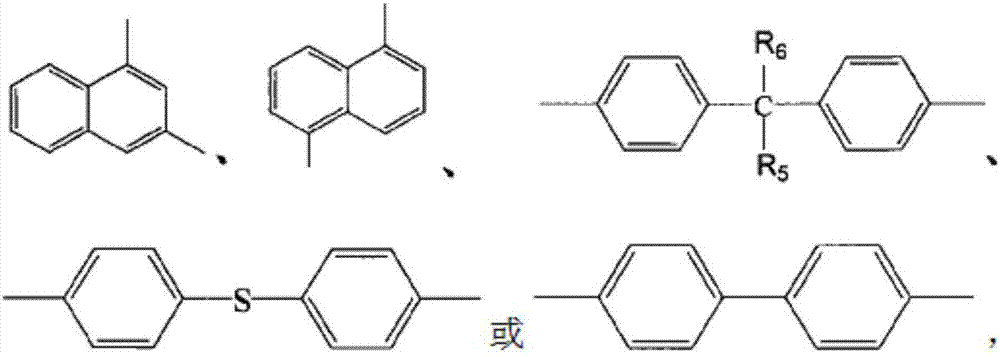

[0022] The invention provides a polylactic acid composition, which contains polylactic acid and aliphatic-aromatic-polylactic acid copolyester products, wherein the content of metal elements in the aliphatic-aromatic-polylactic acid copolyester products Be below 0.02% by weight; And, the preparation method of described aliphatic-aromatic-polylactic acid copolyester product comprises the following steps:

[0023] (1) In the presence of a titanium series catalyst, component a, component b and component c are subjected to an esterification reaction;

[0024] (2) under vacuum conditions, the esterification reaction mixture gained in step (1) is prepolymerized;

[0025] (3) In the presence of a rare earth metal catalyst, the prepolymerization reaction mixture obtained in step (2) is subjected to polycondensation reaction to obtain the product of an aliphatic-aromatic copolymer, wherein, in the aliphatic-aromatic copolymer In the product, the content of the titanium-based catalyst ...

preparation example 1

[0081] Dissolve 9.37 mmol of lanthanum chloride in 50 mL of water, add to an aqueous solution containing 56.2 mmol of acetylacetone, stir at room temperature, and adjust the pH to neutral by adding an aqueous solution of 2N KOH. The reaction mixture was stirred, filtered, and dried under vacuum at 60° C. to obtain 4 g of lanthanum acetylacetonate.

preparation example 2

[0083] Dissolve 9.37mmol of lanthanum chloride in 50mL of water, then add it to an aqueous solution containing 20mmol of sodium stearate, stir at room temperature, and adjust the pH to neutral by adding 2N HCl aqueous solution. The reaction mixture was stirred, filtered, and dried under vacuum at 60°C to obtain 11 g of lanthanum stearate.

[0084] Preparation Example 1

[0085] Add 2.2mol terephthalic acid, 5mol butanediol and 1.6mmol tetrabutyl titanate (purchased from Beijing Chemical Reagent Company, chemically pure) into the reactor, and under nitrogen protection, stir and heat to reflux, the reaction temperature is controlled At 180°C, and collect the distilled water until the water is almost collected (about 2 hours of reaction). Add another 2.5 mol of succinic acid to the system, continue to stir and heat to reflux, control the reaction temperature at 200°C, collect the distilled water until the water is almost completely collected (about 2 hours of reaction). Then, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com