Environment-friendly heat reflection coating and preparation method thereof

A heat reflection and coating technology, applied in reflection/signal coatings, coatings, etc., can solve the problems of low environmental protection coefficient, short heating life of coatings, restricted application, etc., to achieve good heat reflection effect and improve heat reflection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

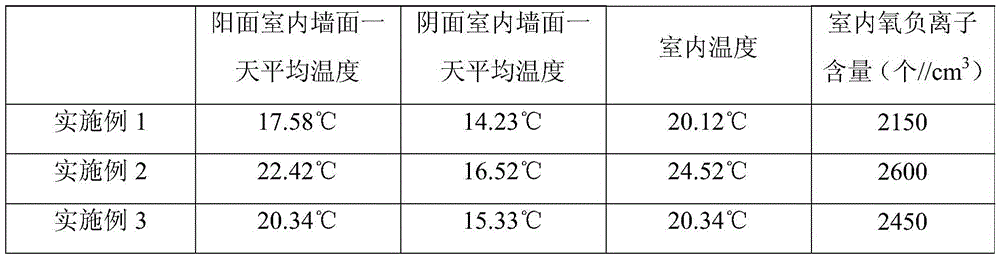

Examples

Embodiment 1

[0017] An environmentally friendly heat-reflective coating, which is composed of the following components in proportion by weight: 20 parts of silicon dioxide, 22 parts of rutile titanium dioxide, 20 parts of acrylic resin, 18 parts of epoxy resin, 8 parts of wollastonite, and sodium borate 3 parts, 8 parts of zinc oxide, 5 parts of heavy calcium, 13 parts of oxygen anion powder, 12 parts of bamboo charcoal powder, 6 parts of wetting agent, 7 parts of defoamer, 7 parts of leveling agent, 9 parts of film-forming aid, water 35 servings.

[0018] A method for preparing a heat reflective coating, comprising the following steps:

[0019] Step 1. Preparation of base material: add acrylic resin and epoxy resin into a high-pressure reactor, react at 355°C and 2.1MPa for 1.5 hours, cool down to room temperature and then granulate, with a particle size of 200 mesh;

[0020] Step 2. Filler preparation: Mix and grind silicon dioxide, rutile titanium dioxide and heavy calcium into a powde...

Embodiment 2

[0023] An environmentally friendly heat-reflective coating, which is composed of the following components in proportion by weight: 36 parts of silicon dioxide, 34 parts of rutile titanium dioxide, 33 parts of acrylic resin, 31 parts of epoxy resin, 20 parts of wollastonite, sodium borate 7 parts, 16 parts of zinc oxide, 8 parts of heavy calcium, 22 parts of oxygen anion powder, 23 parts of bamboo charcoal powder, 9 parts of wetting agent, 10 parts of defoamer, 11 parts of leveling agent, 11 parts of film-forming aid, water 54 copies.

[0024] A method for preparing a heat reflective coating, comprising the following steps:

[0025] Step 1. Preparation of base material: Add acrylic resin and epoxy resin into a high-pressure reactor, react at 380°C and 2.6MPa for 2 hours, cool down to room temperature and then granulate, with a particle size of 300 mesh;

[0026] Step 2. Filler preparation: Mix and grind silicon dioxide, rutile titanium dioxide and heavy calcium into a powder w...

Embodiment 3

[0029] An environmentally friendly heat-reflective coating, which is composed of the following components in proportion by weight: 45 parts of silicon dioxide, 40 parts of rutile titanium dioxide, 40 parts of acrylic resin, 36 parts of epoxy resin, 25 parts of wollastonite, sodium borate 10 parts, 20 parts of zinc oxide, 12 parts of heavy calcium, 25 parts of oxygen anion powder, 26 parts of bamboo charcoal powder, 13 parts of wetting agent, 12 parts of defoamer, 15 parts of leveling agent, 13 parts of film-forming aid, water 60 servings.

[0030] A method for preparing a heat reflective coating, comprising the following steps:

[0031] Step 1. Preparation of base material: add acrylic resin and epoxy resin into the high-pressure reactor, react at 425°C and 3.7MPa for 3 hours, cool down to room temperature and granulate, the particle size is 350 mesh;

[0032] Step 2, filler preparation: mix and grind silicon dioxide, rutile titanium dioxide and heavy calcium into powder, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com