Method for preparing self-healing coating based on environment-friendly nanometer container

An environment-friendly, nano-container technology, applied in coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of toxic substances, complicated preparation steps, etc., and achieve the effects of low cost, simple preparation method, and good protective performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

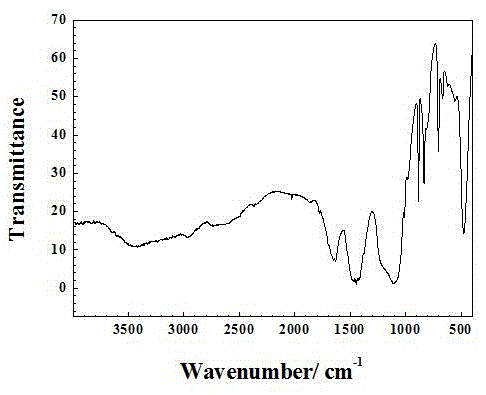

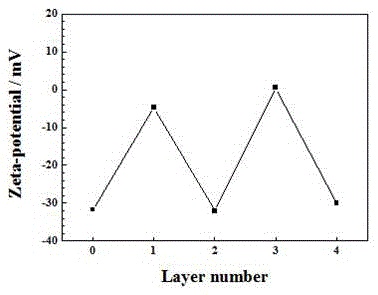

[0029] Take 5 parts nano-SiO 2 Mix with 100 parts of deionized water and magnetically stir for 12h to make SiO 2 Sol-gel solution, the prepared SiO 2 The sol-gel solution was mixed with 5 parts of 5 mg / mL chitosan (CS) solution, magnetically stirred for 20 minutes, ultrasonically dispersed for 20 minutes, and centrifuged for 20 minutes. After centrifugation, the upper layer solution was poured out, and the lower layer of particles was washed with deionized water to obtain CS-coated SiO 2 Particles: SiO 2 / CS. The prepared SiO 2 / CS mixed with 5 parts of 2 mg / mL polyaspartic acid (PASP) corrosion inhibitor aqueous solution, magnetically stirred for 20 minutes, ultrasonically dispersed for 20 minutes, and centrifuged for 20 minutes. , to obtain SiO coated with PASP and CS layer by layer 2 Particles: SiO 2 / CS / PASP. Repeat the above steps to obtain nanocontainer SiO 2 / CS / PASP / CS / PASP. Put the final granules into an oven and dry at 50-60°C for 24 hours for future use. ...

Embodiment 2

[0033] Take 10 parts nano-SiO 2 Mix with 100 parts of deionized water and magnetically stir for 12h to make SiO 2 Sol-gel solution, the prepared SiO 2 The sol-gel solution was mixed with 10 parts of 5 mg / mL chitosan (CS) solution, magnetically stirred for 20 minutes, ultrasonically dispersed for 20 minutes, and centrifuged for 20 minutes. After centrifugation, the upper layer solution was poured out, and the lower layer of particles was washed with deionized water to obtain CS-coated SiO 2 Particles: SiO 2 / CS. The prepared SiO 2 / CS mixed with 10 parts of 5 mg / mL polyaspartic acid (PASP) corrosion inhibitor aqueous solution, magnetically stirred for 20 minutes, ultrasonically dispersed for 20 minutes, and centrifuged for 20 minutes. After centrifugation, pour out the upper layer solution and wash the lower layer of particles with deionized water , to obtain SiO coated with PASP and CS layer by layer 2 Particles: SiO 2 / CS / PASP. Repeat the above steps to obtain nanocon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com