Mutton fat degumming method

A degumming method and lanolin technology are applied in the field of lanolin degumming, which can solve the problems that oil soap cannot be well separated, increase the color of oil, and decrease the quality of lanolin, shorten the enzymatic hydrolysis reaction time, avoid a large amount of waste water, safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

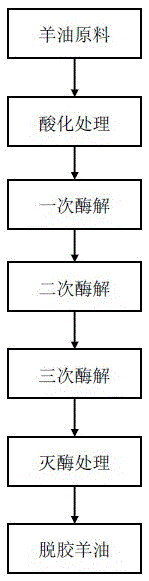

Image

Examples

Embodiment 1

[0031] Add a citric acid solution with a concentration of 45% to the sheep oil raw material, the addition of the citric acid solution is 0.10% of the quality of the sheep oil raw material, and carry out acidification treatment under the assistance of ultrasound, and control the temperature at 80 ° C during the acidification treatment. The ultrasonic intensity is 1.40W / cm 3 , the ultrasonic time is 25 minutes, and after the acidification treatment is completed, the acidified sheep oil is obtained; wherein, the composition content of the sheep oil raw material includes: a moisture content of 0.31%, an insoluble impurity content of 0.09%, and a phospholipid content of 879.26 mg / kg; Add a certain amount of distilled water to the acidified sheep oil, the addition of the distilled water is 3.4% of the quality of the acidified sheep oil, adjust the pH of the acidified sheep oil to 5.0, and add phospholipase A1 for ultrasonic-assisted enzymolysis, the phospholipid The amount of enzyme...

Embodiment 2

[0033] Add a citric acid solution with a concentration of 45% to the sheep oil raw material, the addition of the citric acid solution is 0.12% of the quality of the sheep oil raw material, and carry out acidification treatment under the assistance of ultrasound, and control the temperature at 75 ° C during the acidification treatment. Ultrasonic intensity is 1.50W / cm 3 , the ultrasonic time is 20 minutes, and after the acidification treatment is completed, the acidified sheep oil is obtained; wherein, the composition content of the sheep oil raw material includes: a moisture content of 0.20%, an insoluble impurity content of 0.25%, and a phospholipid content of 1001.42 mg / kg; Add a certain amount of distilled water to the acidified sheep oil, the addition of the distilled water is 3.6% of the acidified sheep oil quality, adjust the pH of the acidified sheep oil to 4.9, and add phospholipase A1 for ultrasonic-assisted enzymolysis, the phospholipid The amount of enzyme A1 added ...

Embodiment 3

[0035] Add a citric acid solution with a concentration of 45% to the sheep oil raw material, the addition of the citric acid solution is 0.14% of the quality of the sheep oil raw material, and carry out acidification treatment under the assistance of ultrasound, and control the temperature at 85 ° C during the acidification treatment. The ultrasonic intensity is 1.60W / cm 3 , the ultrasonic time is 15 minutes, and after the acidification treatment is completed, the acidified sheep oil is obtained; wherein, the composition content of the sheep oil raw material includes: a moisture content of 0.08%, an insoluble impurity content of 0.17%, and a phospholipid content of 1123.58 mg / kg; Add a certain amount of distilled water to the acidified sheep oil, the addition of the distilled water is 3.2% of the acidified sheep oil quality, adjust the pH of the acidified sheep oil to 5.1, and add phospholipase A1 for ultrasonic-assisted enzymolysis, the phospholipid The amount of enzyme A1 ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com