A method for preparing a blackened thermal control film layer with high absorption rate and high emissivity on the surface of red copper

A high emissivity, thermal control film technology, applied in coating, liquid chemical plating, metal material coating process, etc., can solve the harsh reaction conditions of blackened thermal control film layer, poor matrix bonding force, difficult to control accurately and other problems, to achieve the effect of overcoming energy waste and difficulty in precise control, low heating temperature and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

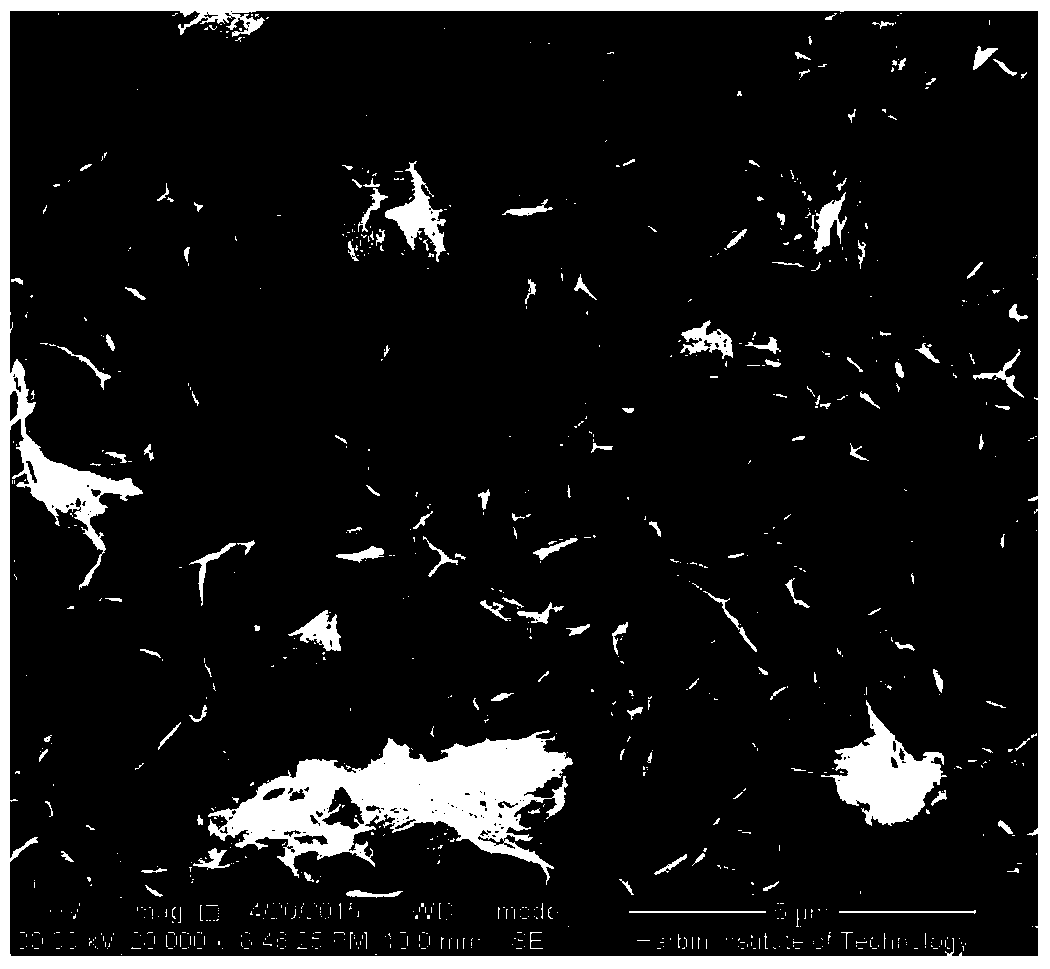

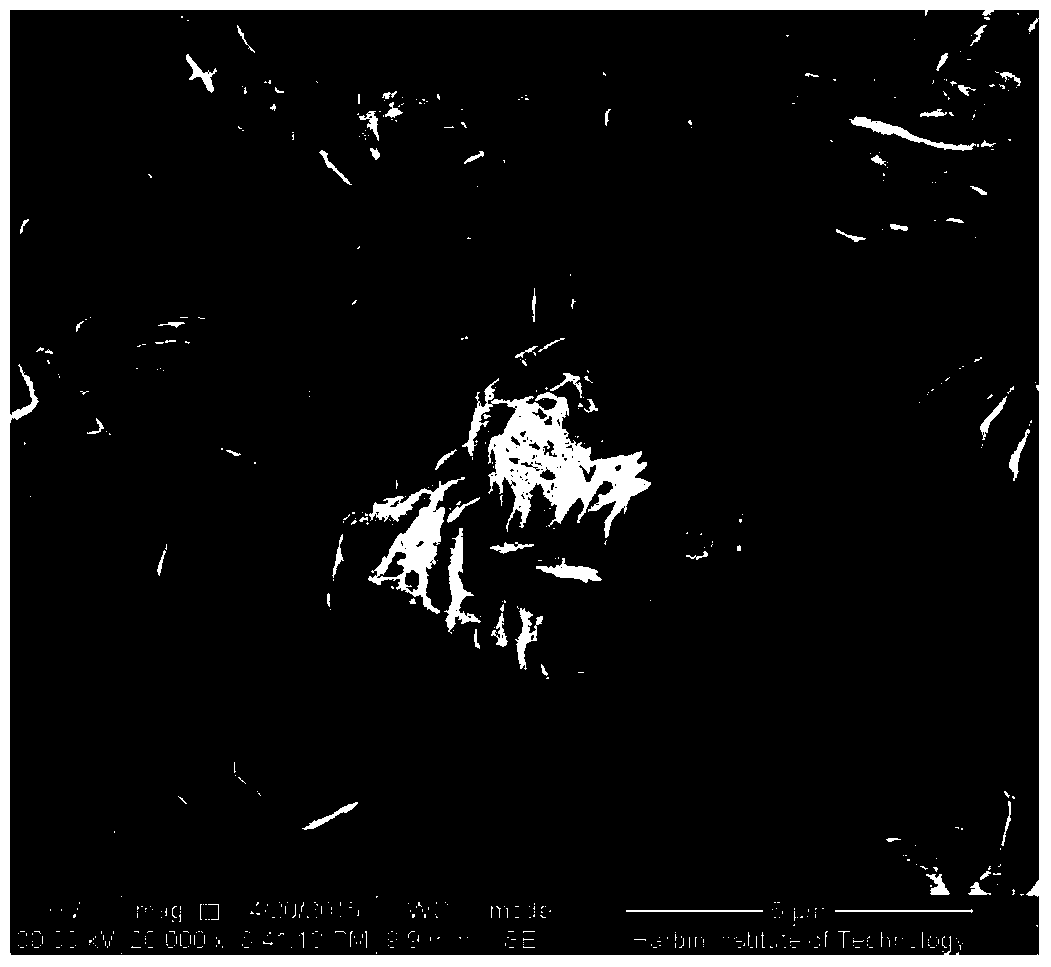

Image

Examples

specific Embodiment approach 1

[0051] Embodiment 1: This embodiment is a method for preparing a blackened thermal control film with high absorptivity and high emissivity on the surface of copper, which is completed in the following steps:

[0052] 1. Pretreatment of copper:

[0053] ①. Use 240#SiC sandpaper, 1000#SiC sandpaper and 1500#SiC sandpaper in sequence to polish the copper to obtain a bright copper sample;

[0054] ②, degreasing, pickling:

[0055] Immerse bright copper in NaOH and NaOH 2 CO 3 Put in the mixed solution for 15min~20min, then use distilled water to wash 3~5 times, then immerse in the pickling solution for 1min~2min, then use distilled water to wash 3~5 times, and then use a hair dryer to dry to obtain the pretreated Copper;

[0056] NaOH and NaOH and Na mentioned in step ② 2 CO 3 The mixture consists of NaOH, Na 2 CO 3 Prepared by mixing with water; the NaOH and Na 2 CO 3 The mass fraction of NaOH in the mixed solution is 10% to 25%, and the NaOH 2 CO 3 The mass fraction ...

specific Embodiment approach 2

[0085] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 2, the pretreated red copper obtained in step 1 ② is immersed in a deposition solution with a temperature of 40°C, The deposition reaction was carried out for 30 minutes to obtain red copper with a blackened thermal control film layer deposited on the surface. Others are the same as the first embodiment.

specific Embodiment approach 3

[0086] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, the pretreated red copper obtained in step one (2) is immersed in the deposition solution with a temperature of 60°C, and then the temperature is The deposition reaction was carried out at 60° C. for 30 minutes to obtain red copper with a blackened thermal control film deposited on the surface. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com