Sectioned laser cladding remanufacturing method with preheating and heat treatment for complex parts

A technology of laser cladding and cladding layer, applied in the direction of metal material coating process, coating, etc., can solve the problems of complex crack shape and short length of parts, and achieve the effect of increasing temperature, preventing crack generation and prolonging cooling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

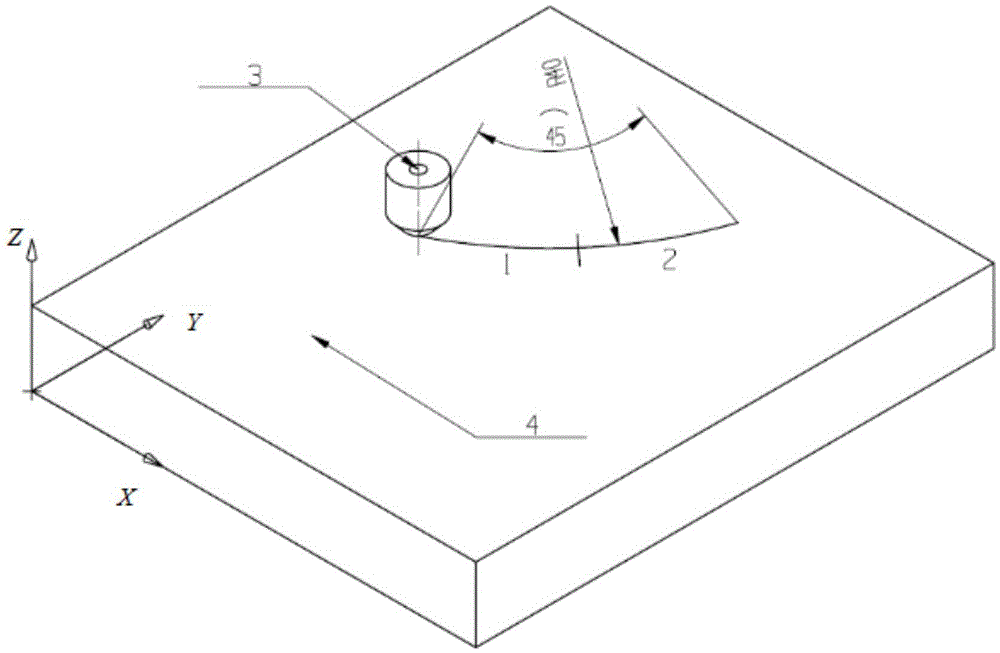

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The specific process of the segmented laser cladding remanufacturing method is as follows:

[0022] Step 1: On the basis of single-pass single-layer laser cladding, combined with the shape of the laser cladding track and the complexity of the workpiece, determine the laser cladding parameters through experimental trial and error and experience, including laser cladding power, powder feeding volume and scanning speed.

[0023] The laser cladding base material and cladding material are AISI321 and AISI316L austenitic stainless steel respectively. AISI316L austenitic stainless steel has the following characteristics: the transformation of martensite is not involved in the solidification process, so the cause of residual stress can be excluded. Tensitic transformation, in addition, AISI316L austenitic stainless steel has good welding performance, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com