A method of using biological fermentation liquid in ramie degumming torture process

A ramie and degumming technology, applied in the field of microorganisms, can solve the problems of reducing the residual glue rate, high residual glue rate of fine-dried hemp, prolonging the processing time and high cost of processing strength, and achieving the effect of improving quality and reducing the residual glue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 bacterial liquid culture

[0016] Use Bacillus sp.HG-116 as the strain, go through the strain activation step and the expanded culture step to obtain bacterial solution A; use Bacillus sp.HG-247 as the strain, and go through the strain activation step and the expanded culture step respectively Obtain bacterial solution B;

[0017] Ⅰ. Preservation, activation and expansion of Bacillus sp.HG-116

[0018] Strain storage: Inoculate Bacillus sp.HG-116 strains into 250mL shake flasks filled with 80mL No. 1 medium according to the inoculum amount of 1%, and cultivate them at 36°C and 180r / min for 3 hours. The cultured bacterial solution was stored at -20°C with the glycerol seed preservation method to obtain the HG-116 strain tube;

[0019] Activation: Place the HG-116 strain tube at room temperature for 3 minutes until the bacterial solution melts, then inoculate 1.2% of the inoculum into a 1L shaker flask containing 250mL No. Cultivate under the condition for...

Embodiment 2

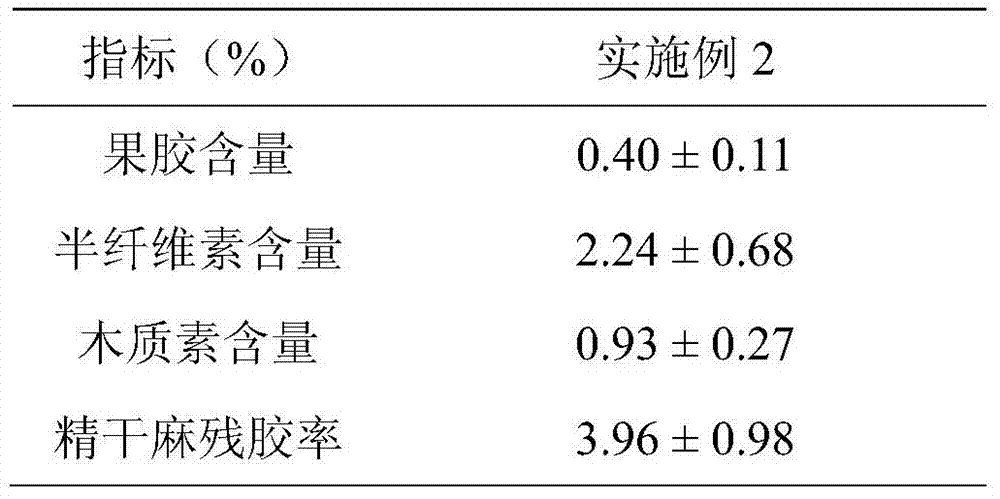

[0032] Example 2 Torture

[0033] Mix the bacteria solution A and the bacteria solution B in Example 1 according to a volume ratio of 1:1 to obtain a mixed bacteria solution, dilute the mixed bacteria solution with water 5 times to obtain a diluted mixed bacteria solution, and use the diluted mixed bacteria solution as a ramie degumming torture process torture fluid. The loading amount of degummed ramie is 5kg / m 2 , inject the torturing liquid to submerge the degummed ramie, and the flow rate of the torturing liquid is 0.05m 3 / min, the hammer hitting frequency is 30 times / min, and the hammer hitting pressure is 4×10 5 Continuously torturing the degummed ramie for 5 minutes at a temperature of 30°C. The torture solution was recycled twice, and a mixed bacterial solution with a volume fraction of 5% was added each time it was recycled. The experimental results of Example 2 are shown in Table 2 below.

[0034] The experimental result of table 2 embodiment 2

[0035]

Embodiment 3

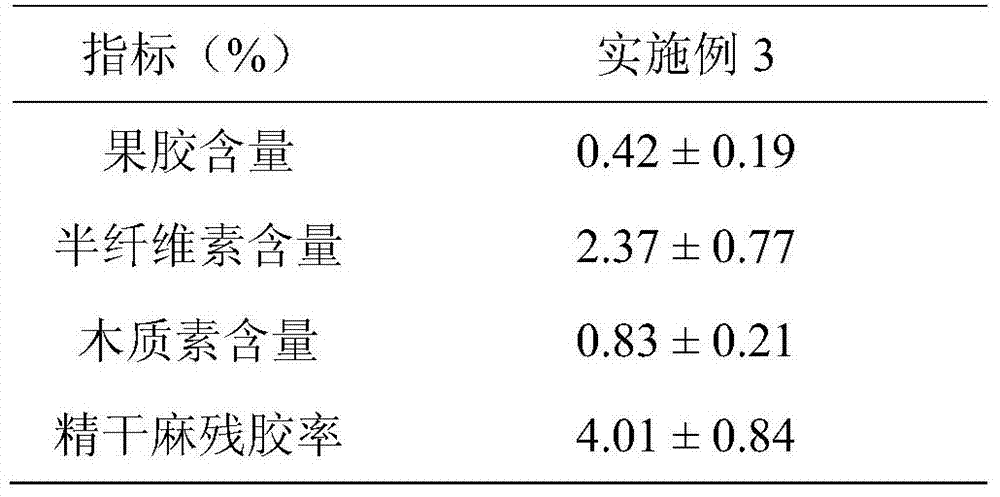

[0036] Example 3 Torture

[0037] Mix the bacteria solution A and the bacteria solution B in Example 1 according to the volume ratio of 5:1 to obtain a mixed bacteria solution, dilute the mixed bacteria solution with water 50 times to obtain a diluted mixed bacteria solution, and use the diluted mixed bacteria solution as a ramie degumming process torture fluid. The loading amount of degummed ramie is 50kg / m 2 , inject the torturing liquid to submerge the degummed ramie, and the flow rate of the torturing liquid is 3m 3 / min, the hammer hitting frequency is 300 times / min, and the hammer hitting pressure is 5×10 4 Continuously torturing the degummed ramie for 25 minutes at Pa and a temperature of 45°C. The torture solution was recycled 5 times, and a mixed bacterial solution with a volume fraction of 0.05% was added each time it was recycled. The experimental results of Example 3 are shown in Table 3 below.

[0038] The experimental result of table 3 embodiment 3

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com