A method for preparing textile fibers from raw hemp by degumming with an organic solvent

An organic solvent and raw hemp technology, applied in the field of raw hemp degumming, can solve problems such as cellulose damage, achieve the effects of reducing surface tension, simple and efficient damage, and low residual glue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

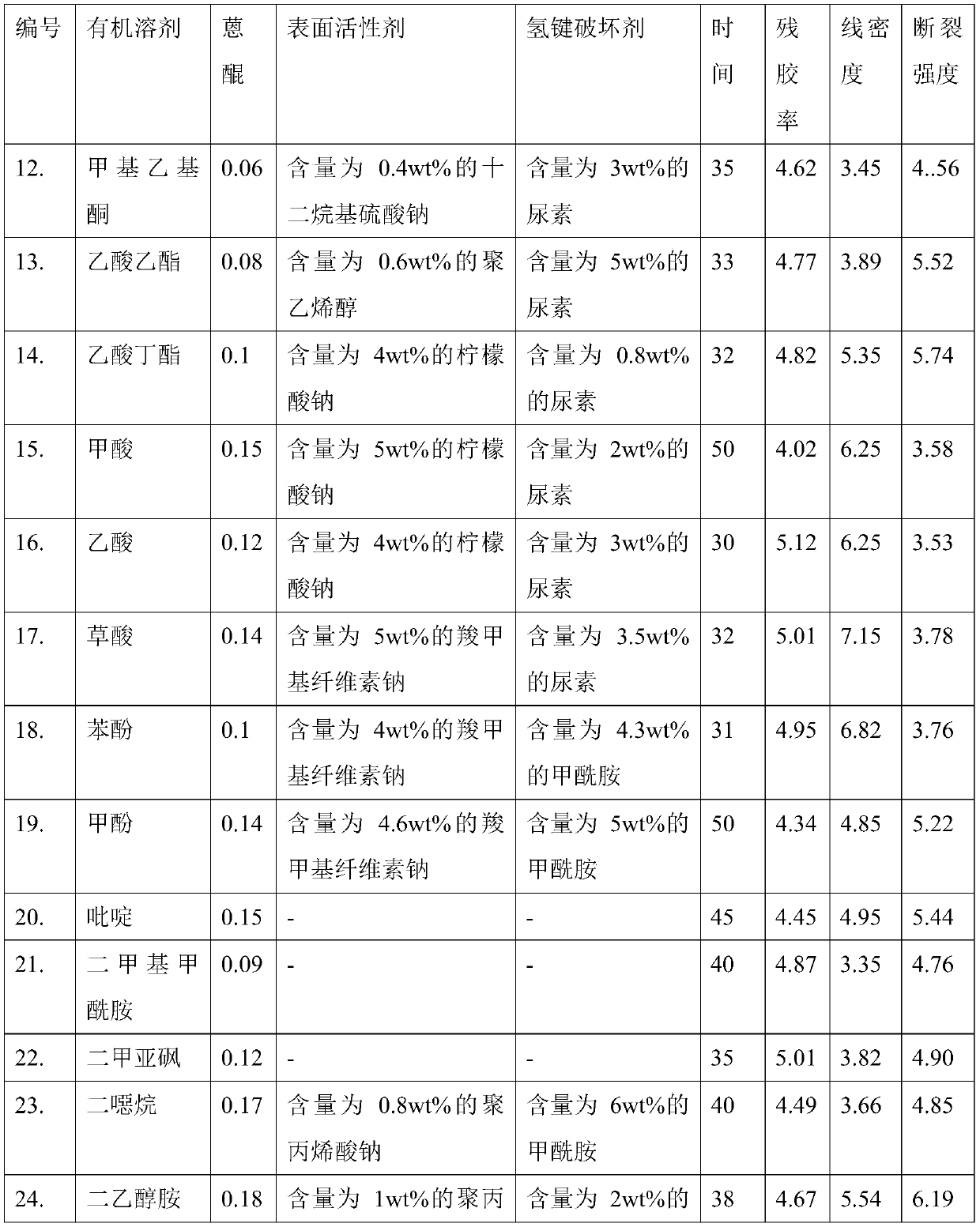

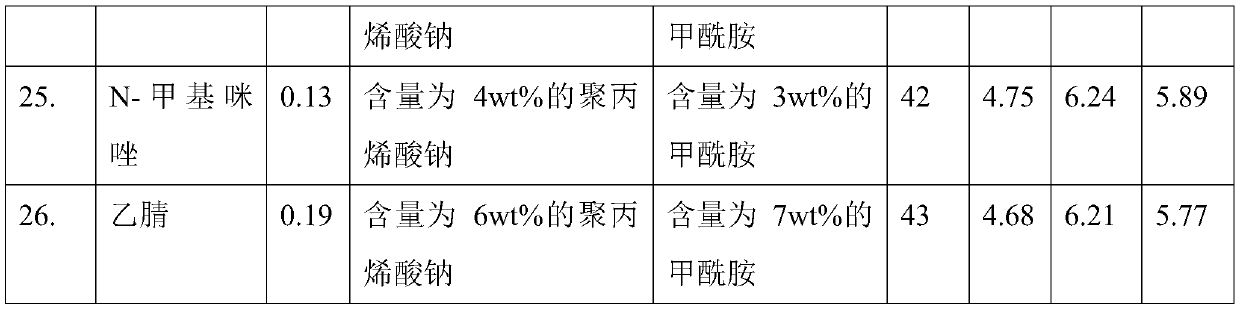

Examples

Embodiment 1

[0037] A method for preparing textile fibers with raw hemp through degumming with an organic solvent, the steps are as follows:

[0038] (1) prepare degumming solution;

[0039] The degumming solution is an anhydrous system composed of ethylene glycol and anthraquinone, and the content of anthraquinone in the degumming solution is 0.1wt%;

[0040] (2) Set up a circulating closed system;

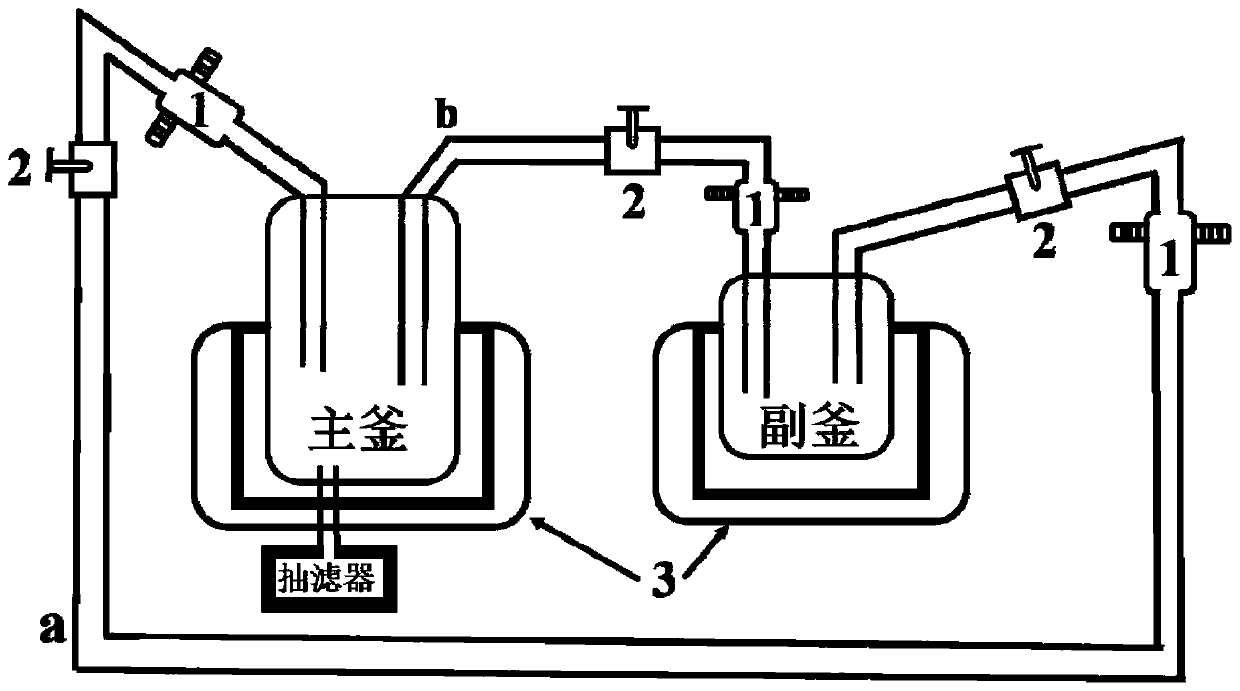

[0041] Such as figure 1 As shown, the circulating closed system is mainly composed of a main kettle and an auxiliary kettle. The heating device 3 is respectively installed on the main kettle and the auxiliary kettle. A closed loop is formed between the main kettle and the auxiliary kettle through a pipeline a and a pipeline b. Both are equipped with valve 2 and condenser 1;

[0042] (3) First, mix the prepared degumming solution and ramie raw hemp in the main kettle of the closed system at a weight ratio of 1:30, then heat the main kettle and the auxiliary kettle to 200°C, and heat the mix...

Embodiment 2

[0049] A method for preparing textile fibers with raw hemp through degumming with an organic solvent, the steps are as follows:

[0050] (1) prepare degumming solution;

[0051] The degumming solution is an anhydrous system composed of glycerol and anthraquinone, and the content of anthraquinone in the degumming solution is 0.01wt%;

[0052] (2) Set up a circulating closed system;

[0053] The structure of the closed loop system is identical to that of Example 1;

[0054] (3) First, mix the prepared degumming liquid and hemp raw hemp in the main kettle of the closed system at a weight ratio of 1:20, then heat the main kettle and the auxiliary kettle to 180°C, and heat the mixture under a pressure of 0.6MPa. Next, use the degumming liquid in the circulating closed system to treat the raw cannabis for 0.5 hours. During the treatment process, the circulating closed system realizes the circulation of the degumming liquid through continuous distillation, condensation and reflux, ...

Embodiment 3

[0057] A method for preparing textile fibers with raw hemp through degumming with an organic solvent, the steps are as follows:

[0058] (1) prepare degumming solution;

[0059] The degumming solution is an anhydrous system consisting of 1,2-propanediol, sodium citrate, urea and anthraquinone. In the degumming solution, the contents of anthraquinone, sodium citrate and urea are 0.05wt%, 0.2wt% and 0.2wt% respectively %;

[0060] (2) Set up a circulating closed system;

[0061] The structure of the closed loop system is identical to that of Example 1;

[0062] (3) First, mix the prepared degumming solution and kenaf raw hemp in the main kettle of the closed system at a weight ratio of 1:15, then heat the main kettle and the auxiliary kettle to 198°C, and heat the mixture under a pressure of 0.2MPa. Next, use the degumming solution in the circulating closed system to treat the raw kenaf for 1 hour. During the treatment process, the circulating closed system realizes the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com