Gene recombinant plasmid, gene recombinant pichia pastoris and straw fiber degumming application

A gene recombination, Pichia pastoris technology, applied in application, fiber processing, genetic engineering and other directions, can solve the problems of surface adhesion of impurities, uneven thickness, fiber damage, etc., to achieve high degumming efficiency, low cost, and fiber residue. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

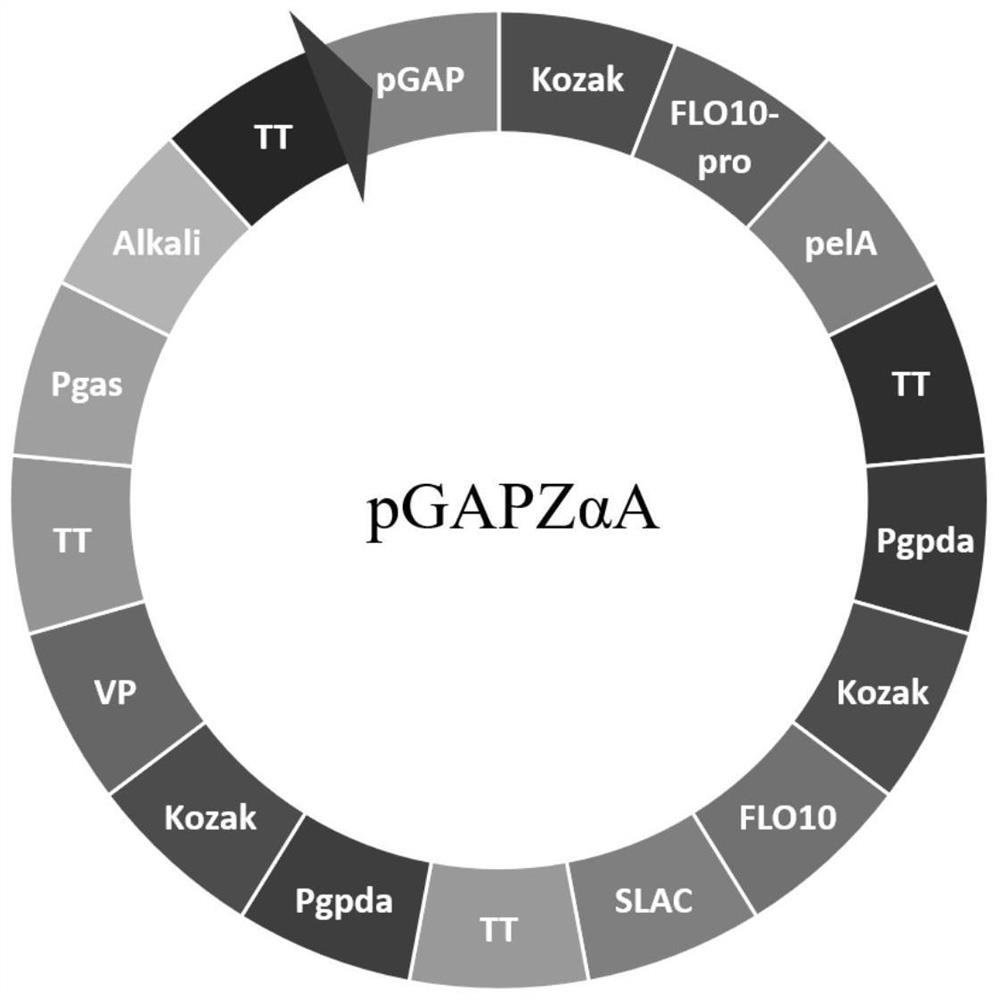

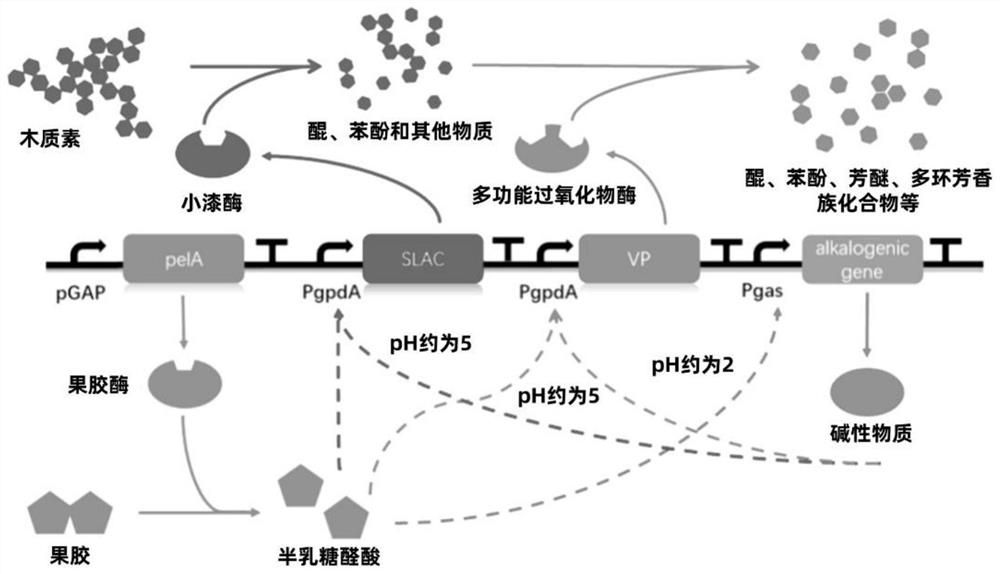

[0035] The present invention uses the ppic9k plasmid as a carrier to design and synthesize the gene pathway for fiber degumming. The specific plasmid structure is as follows: figure 1shown. Select the ppic9k plasmid vector, select the pectin degrading enzyme gene pelA (pectate lyase) found in Aspergillus niger EIM-6, the multifunctional peroxidase gene VP (Versatile peroxidase) found in Pleurotus ostreatus, and the small laccase gene SLAC (Small laccase), Kozak ribosome binding sequence, self-designed basic gene Alkali. Each gene, promoter and terminator (TT) were sequentially connected to the ppic9k plasmid vector by using Gibson Assembly technology. like image 3 As shown, the sequence is pGAP constitutive promoter, Kozak ribosome binding site, FLO10-pro signal peptide gene modified pelA gene, terminator (TT); acid-sensitive promoter Pgpda, Kozak ribosome binding site, FLO10 Signal peptide gene modified SLAC gene, terminator (TT); acid-sensitive promoter Pgpda, Kozak ribo...

Embodiment 2

[0037] Select Pichia pastoris GS115 as the biological chassis, and use electroporation technology to introduce the recombinant plasmid pGAPZαA into GS115, including the following steps:

[0038] a. Take out 80-100 μL of Pichia pastoris medium for continuous culture into a centrifuge tube and put it in an ice water bath;

[0039] b. Add 7-15 μL of linearized pGAPZαA recombinant plasmid, and put it in an ice-water bath for 5 minutes;

[0040] c. Connect the pre-cooled electrodes, and stimulate with 1500v, 5ms, 200Ω and 25μF electricity;

[0041] d. Immediately after stimulation, add 1mL, 1mol / L sorbitol solution (to increase the permeability of the cell membrane, in the Pichia pastoris expression system, adding sorbitol also has the effect of carbon source), and mix thoroughly;

[0042] e. 30°C water bath for 1-2h, add 1mL medium, continue water bath for 1-2h;

[0043] f. Centrifuge at 12000rpm for 0.5min, remove the supernatant, then add 1mL of culture medium and antibiotics ...

Embodiment 3

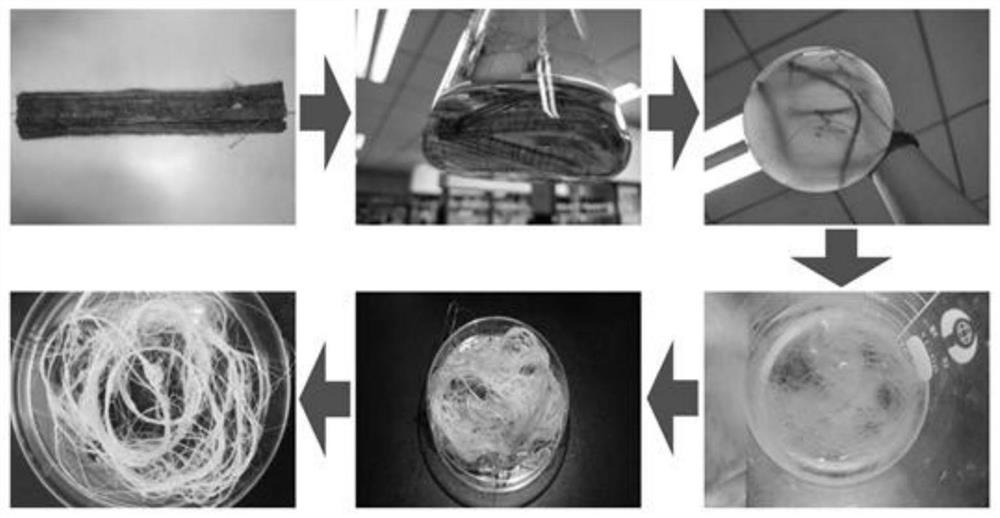

[0045] Straw fiber degumming of the present invention such as figure 2 as shown, figure 2 The six steps shown are:

[0046] (1) Raw material straw;

[0047] (2) Carry out pretreatment to straw, use mechanical rolling to process;

[0048] (3) Carry out constant turbidity continuous culture together with the cultivated engineering yeast thallus;

[0049] (4) Obtain the processed fiber, and extract by-products such as hemicellulose and galacturonic acid from the fermented liquid taken out from constant turbidity culture;

[0050] (5) bleaching, drying, etc. are carried out as required by the fiber obtained;

[0051] (6) Obtain straw fiber crude product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com