A method of extracting and degumming banana fiber by steam explosion technology

A banana fiber and degumming technology, which is applied in the chemical post-processing of fibers, fiber treatment, textiles and papermaking, etc., can solve the problems of uneven strength of banana fibers, low average breaking strength, and inconspicuous removal. The effect of printing quality, improving yield and reducing residual glue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

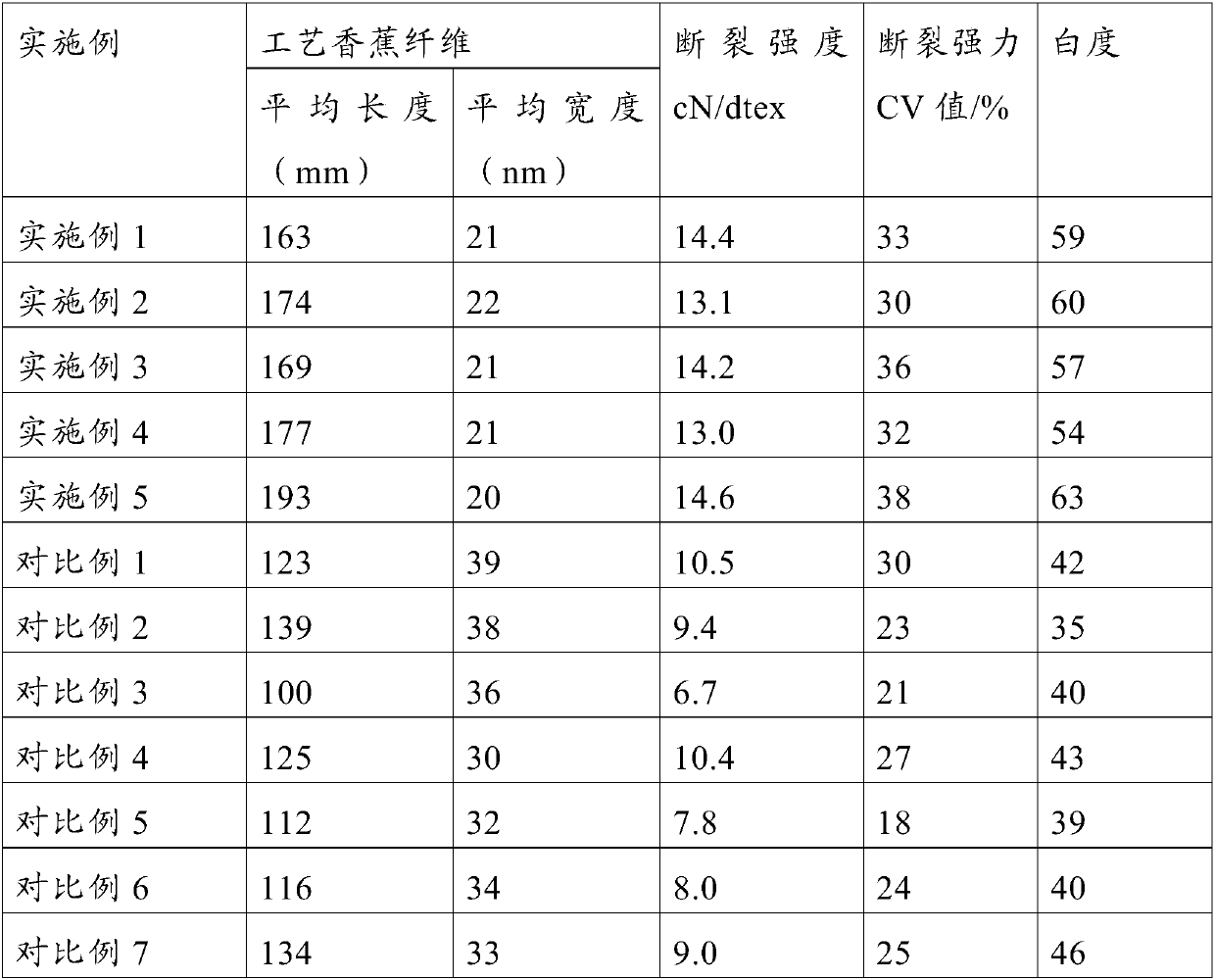

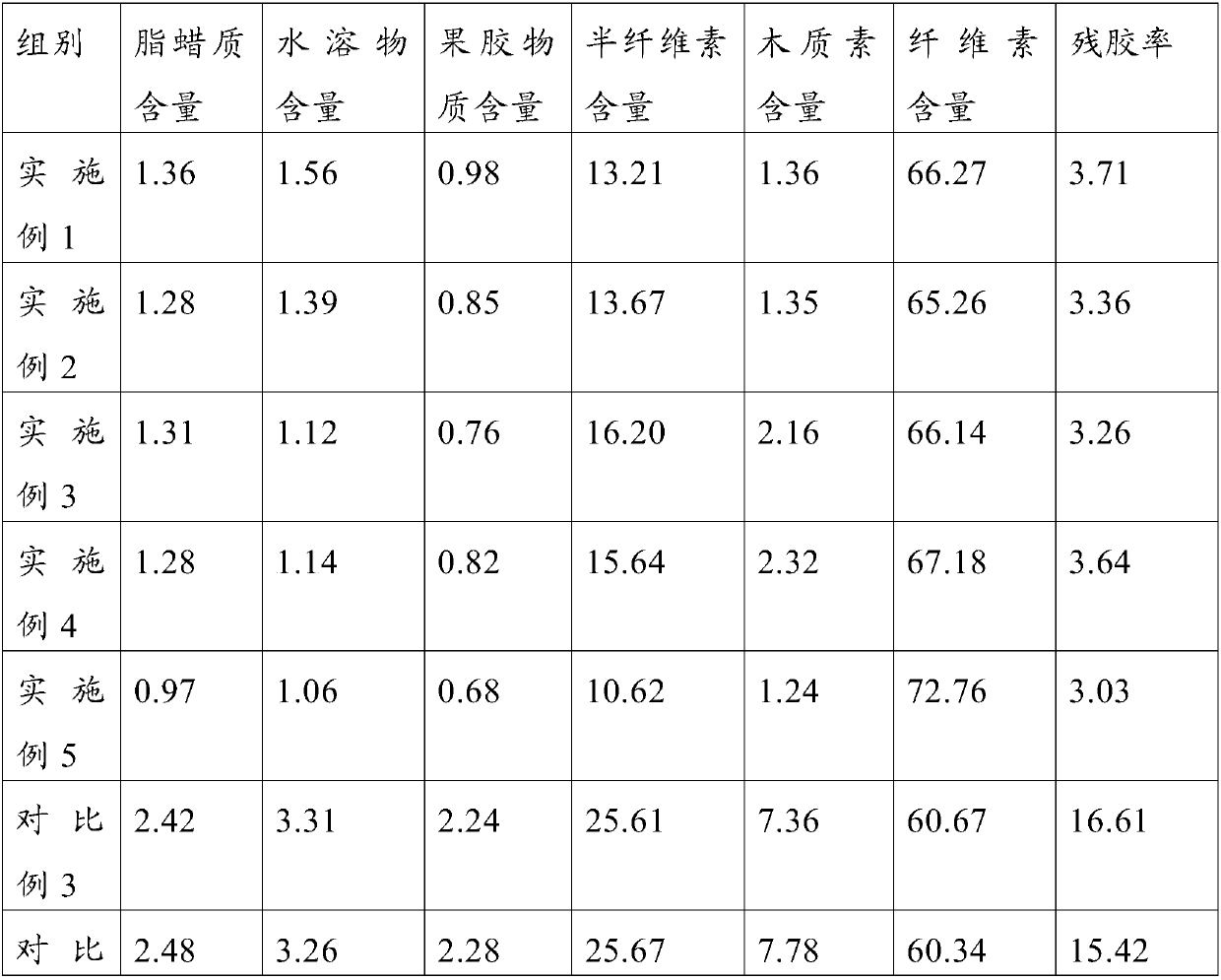

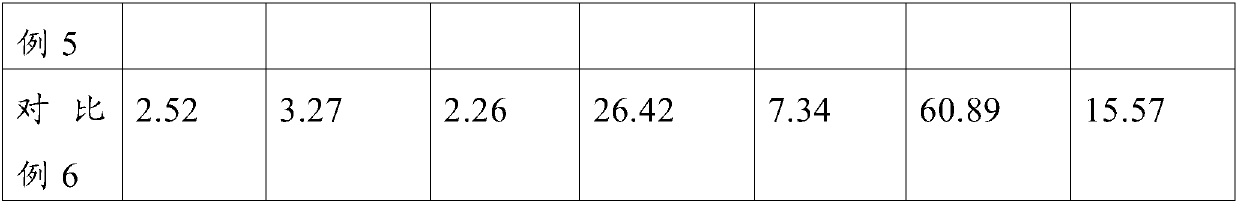

Examples

Embodiment 1

[0029] A method utilizing steam explosion technology to extract and degumming banana fiber, comprising the following steps:

[0030] 1) Steam explosion extraction: Take fresh banana stalks and leaves, cut them, put them in a steam explosion tank, hold them under a steam explosion pressure of 1.7Mpa for 70s, release them instantly, wash them with water and dehydrate them to obtain banana crude fibers.

[0031] 2) Pre-acid treatment: soak the banana crude fiber in an acid solution with a concentration of 0.5%, and carry out high-temperature cooking with a solid-to-liquid ratio of 1:15; Composition, and the weight ratio is 50:1:0.1, the penetrant is penetrant JFC-1.

[0032] 3) Washing: wash the crude banana fiber after high-temperature cooking in warm water at 20° C., the temperature of the high-temperature cooking is 80° C., and the time is 10 hours.

[0033] 4) Enzyme degumming: degumming treatment is carried out by using a compound enzyme, the compound enzyme is hemicellulas...

Embodiment 2

[0039] A method utilizing steam explosion technology to extract and degumming banana fiber, comprising the following steps:

[0040] 1) Steam explosion extraction: take fresh banana stalks and leaves, cut them, put them into a steam explosion tank, press them for 200s under a steam explosion pressure of 3.0Mpa, release them instantly, wash them with water and dehydrate them to obtain banana crude fibers.

[0041] 2) Pre-acid treatment: soak the banana crude fiber in an acid solution with a concentration of 2%, and carry out high-temperature cooking; the acid solution is composed of water, hydrochloric acid solution or dilute nitric acid solution and a penetrant Composition, and the weight ratio is 100:10:2, the penetrant is low foam penetrant SF.

[0042] 3) Washing: wash the crude banana fiber after high-temperature cooking in warm water of 50° C., the temperature of the high-temperature cooking is 100° C., and the time is 20 hours.

[0043] 4) Enzyme degumming: degumming tr...

Embodiment 3

[0049] A method utilizing steam explosion technology to extract and degumming banana fiber, comprising the following steps:

[0050] 1) Steam explosion extraction: take fresh banana stalks and leaves, cut them, put them into a steam explosion tank, press them for 100s under a steam explosion pressure of 2.0Mpa, release them instantly, wash them with water and dehydrate them to obtain banana crude fibers.

[0051] 2) Pre-acid treatment: soak the banana crude fiber in an acid solution with a concentration of 1%, and carry out high-temperature cooking; the acid solution is composed of water, hydrochloric acid solution or dilute nitric acid solution and a penetrant Composition, and the weight ratio is 70:5:0.5, the penetrant is penetrant JFC-1.

[0052] 3) Washing: wash the crude banana fiber after high-temperature cooking in warm water of 30° C., the temperature of the high-temperature cooking is 85° C., and the time is 12 hours.

[0053] 4) Enzyme degumming: degumming treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com