Marine riser and offshore drilling system

An offshore drilling and riser technology, which is applied to underwater drilling, drilling equipment, drill pipes, etc., can solve the problems of waste of resources, large amount of engineering, and large area, so as to reduce engineering difficulty and slow down the sinking speed. , the effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

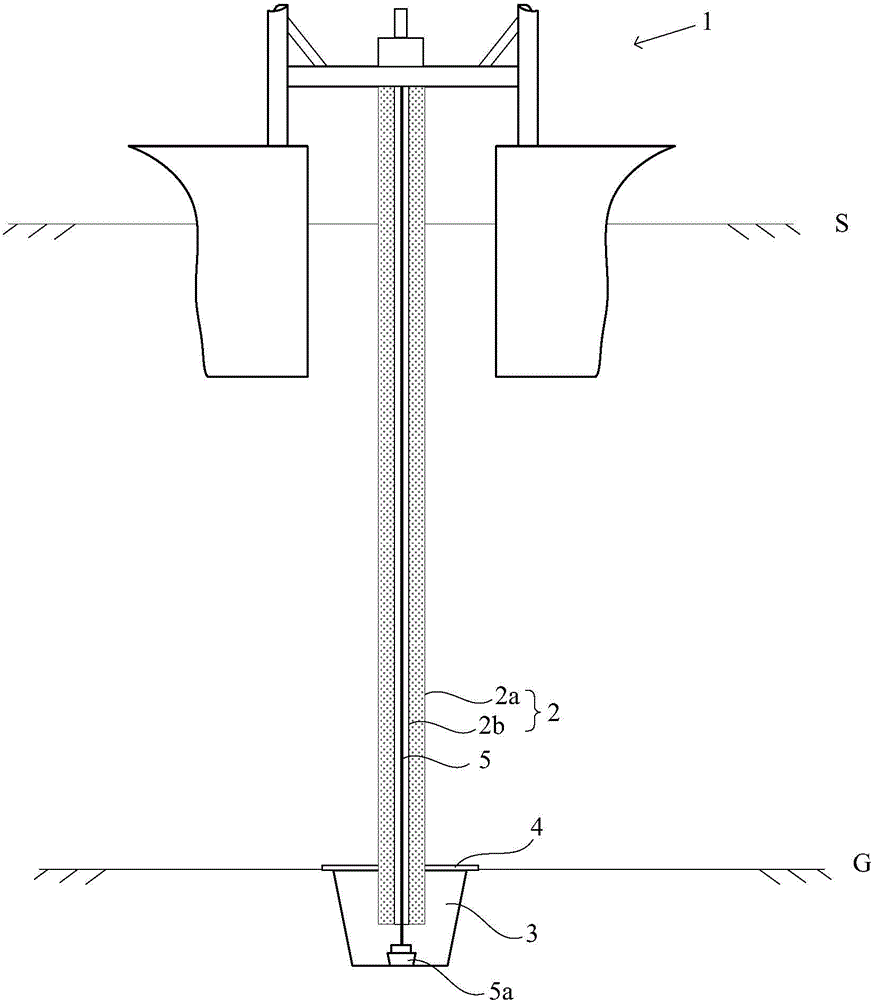

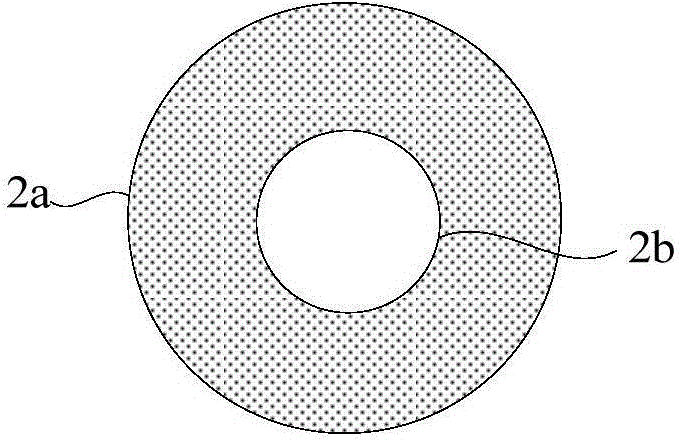

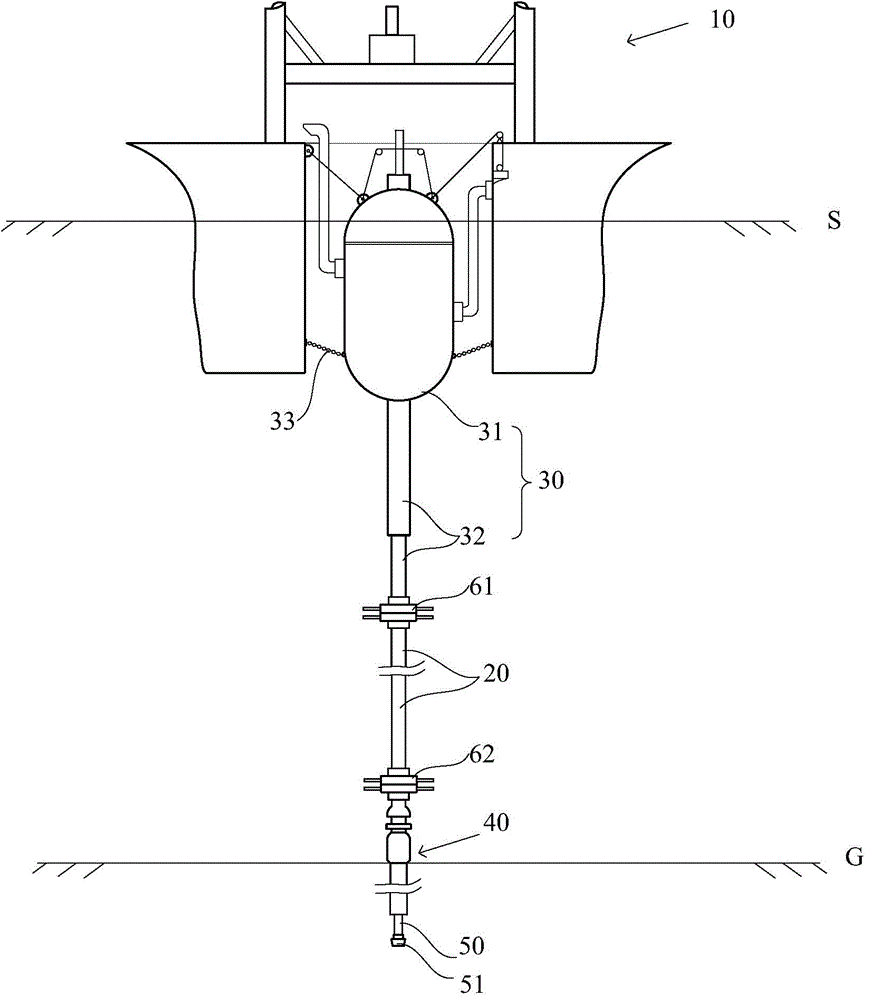

[0060] Since the drilling operation may be carried out in the sea area with a water depth of 3000m, the pressure on the riser at the end close to the seabed is very high. In order for the riser to resist water pressure, the riser wall needs to have sufficient thickness, which greatly increases the riser's volume and weight.

[0061] In order to meet the buoyancy requirements, the diameter of the outer pipe (that is, the outer diameter of the riser) is very large. For example, the outer diameter of each riser in the "981" drilling platform is 1.37m. Taking the length of 22m as an example, the heaviest each riser At least 65 tons, the weight of the 3000m long riser will reach 7000 tons. Due to the huge volume and weight, when installing the riser, the connection between adjacent risers and between the riser and other devices can basically only be connected by screws, which is laborious and time-consuming, and the installation efficiency is very low.

[0062] In order to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com