Treatment equipment, treatment system and treatment method for enabling drilling fluid not to fall to ground

A technology for processing equipment and drilling fluid, which is applied in the direction of earthwork drilling, wellbore/well parts, etc., can solve problems such as soil compaction, insufficient liquid phase reuse, and damage to soil physical properties, so as to solve secondary pollution and facilitate trucking The effects of loading and transportation and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

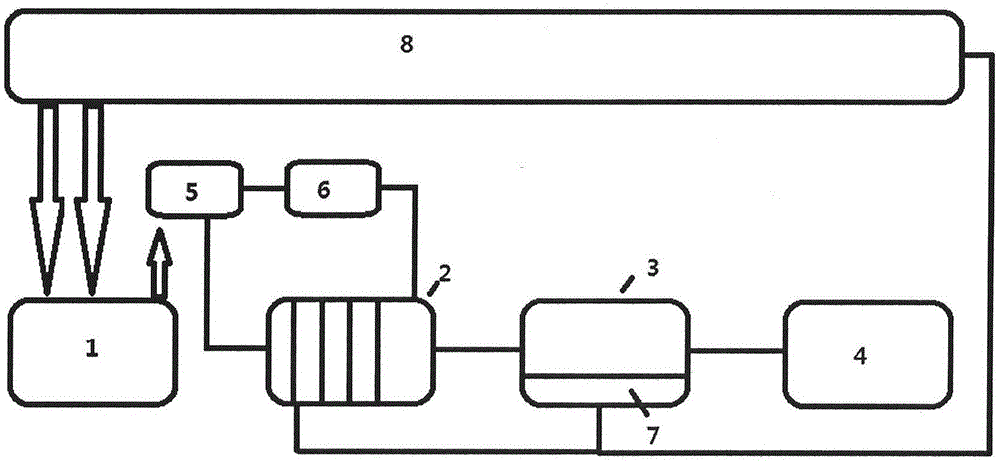

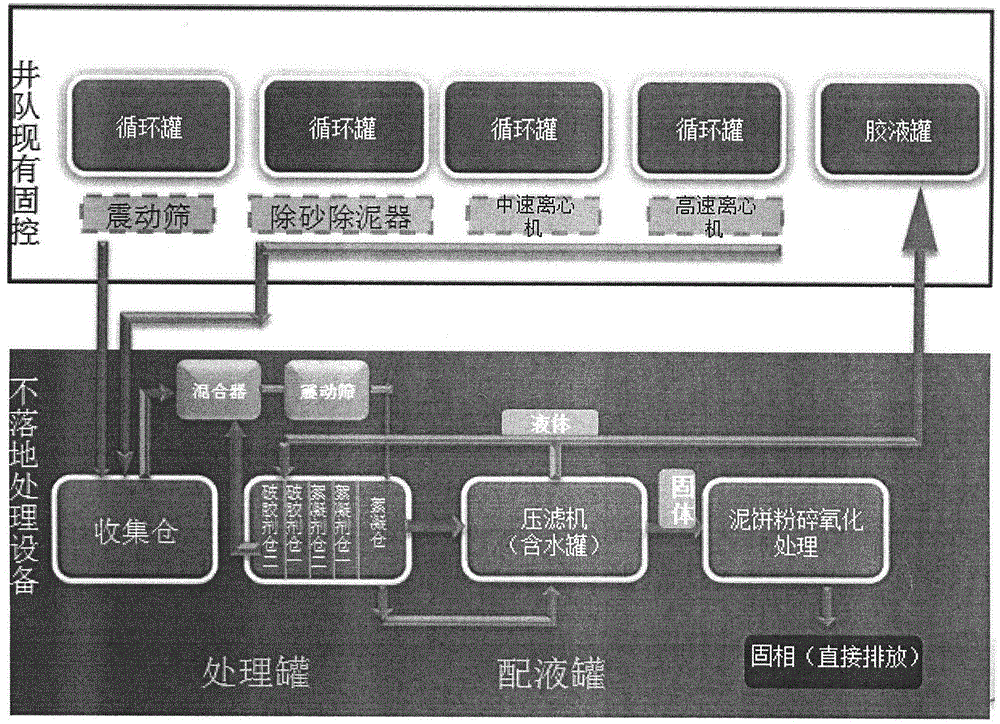

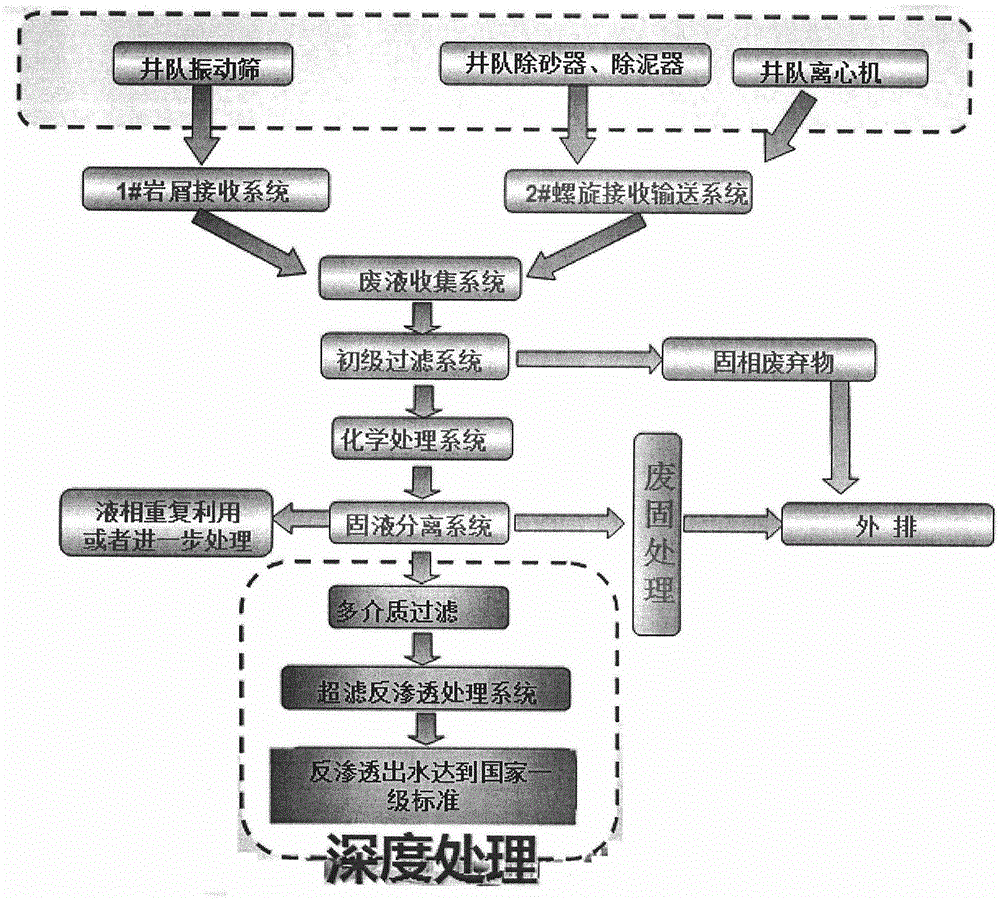

[0049]In a preferred embodiment, a drilling fluid non-landing processing equipment includes a collection unit 1, a chemical treatment unit 2, a solid-liquid separation unit 3, a crushing oxidation unit 4, a mixer 5 and a vibrating screen 6, and the collection unit 1 includes The feeding device and the discharging device, the feeding device is connected to the solid control equipment 8 and collects materials from the solid control device 8, the discharging device is connected to the chemical processing unit 2 and transports the material to the chemical processing unit 2; the chemical processing unit 2 includes device and flocculation device, which receive the material transported by the collection unit 1 and perform gel breaking and flocculation treatment on the material; the chemical proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com