Ferrite particle powder for bonded magnet, resin composition for bonded magnet, and molded article using ferrite particle powder and resin composition

A technology of resin composition and bonded magnet, which is applied in the fields of ferrite particle powder for bonded magnets and resin composition for bonded magnets, can solve the problems of high price and limitation, and achieve excellent tensile elongation, magnetic Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087]

[0088] Weigh powdered α-Fe so that the molar ratio becomes 2Fe:Sr=5.90:1 2 o 3 and SrCO 3 , after mixing for 30 minutes using a wet mill, filter and dry. SrCl was added to the obtained raw material mixed powder 2 and Na 2 B 4 o 7 The aqueous solution is mixed thoroughly and then granulated. At this time, SrCl 2 and Na 2 B 4 o 7 The addition amount of the powder was set to 2.0% by weight and 0.2% by weight with respect to the above-mentioned raw material mixed powder. The obtained granulated material was baked at 1120 degreeC for 2 hours in air|atmosphere. The obtained fired product was roughly pulverized, then pulverized by a wet mill for 30 minutes, washed with water, filtered, and dried. Then, a mixed solution of isopropanol and triethanolamine was added, and further pulverized by a vibration mill for 30 minutes. At this time, mixed solutions of isopropanol and triethanolamine were added in amounts of 0.2% by weight and 0.1% by weight to the above-men...

Embodiment 2

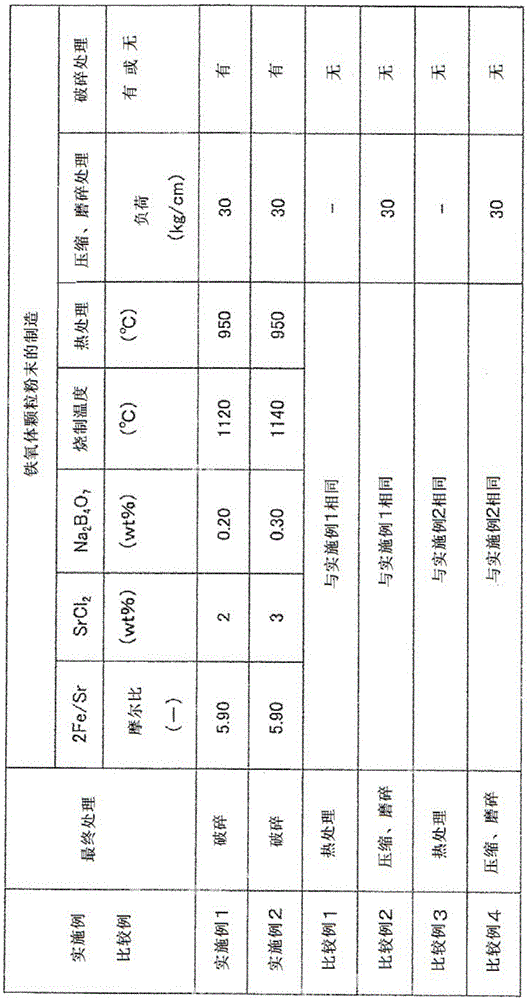

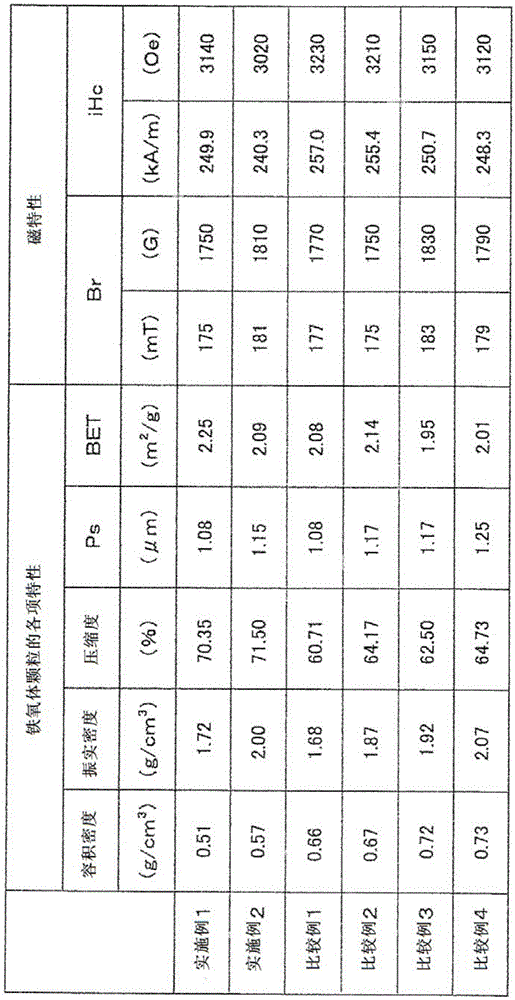

[0090] Ferrite particle powder was produced in the same manner as in Example 1 above except that the composition, the type and amount of additives, the firing temperature, and the like were changed in various ways.

[0091] The production conditions at this time are shown in Table 1, and the characteristics of the obtained ferrite particle powder for bonded magnets are shown in Table 2.

Embodiment 3

[0097]

[0098] Add 25000g of the ferrite particle powder obtained in Example 1 to the Henschel mixer, add 0.6wt% aminoalkyl silane coupling agent relative to the ferrite particle powder, mix for 20 minutes until uniform, and then add 3067 g of 12-nylon resin with a relative viscosity of 1.60 was mixed for another 30 minutes to prepare a mixture of resin compositions for bonded magnets.

[0099] The obtained bonded magnet composition mixture was quantitatively supplied to a twin-screw kneader, kneaded at a temperature at which 12-nylon melts, and the kneaded product was formed into strands, taken out, and cut into The resin composition for bonded magnets was obtained in the form of pellets of different sizes.

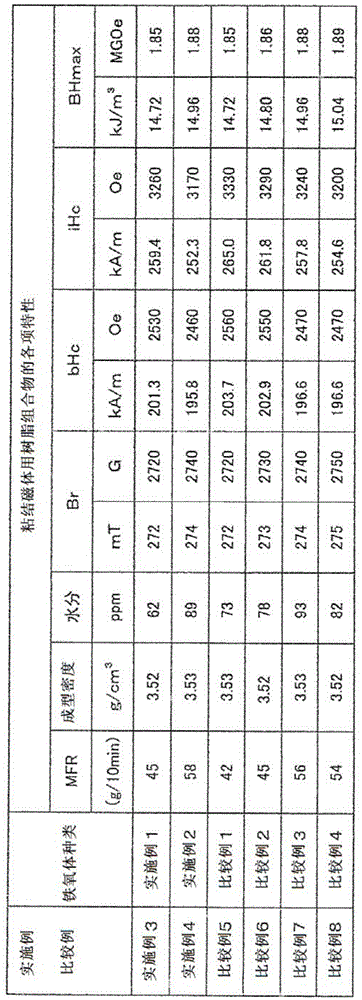

[0100] Table 3 shows the production method and characteristics of the resin composition for bonded magnets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com